5-33

MAINTENANCE

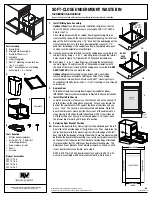

7. Clean the primary element (3) with dried

compressed air (294 to 490 kPa or 43 to

71 psi).

First blow the air from the inside of the

element along the pleats. Then blow the

air from the outside and finally from the

inside again.

8. Light up the inside of the primary element

(3) with a light bulb, inspect it, and replace

it if there are small holes or thin spots.

9. Remove the cloth or tape applied in step

5.

10. Install the primary element (3).

11. Install the dust cup (2) with its

“ TOP ” mark facing up or by

aligning the arrows “ / ”, and then

fasten it with the clamps (1).

EVERY 250 HOURS

Содержание TB128FR

Страница 1: ...C 1...

Страница 10: ...0 8...

Страница 11: ...1 1 SAFETY...

Страница 44: ...1 34 SAFETY SAFETY SIGNS DECALS...

Страница 45: ...1 35 SAFETY SAFETY SIGNS DECALS...

Страница 46: ...1 36 SAFETY SAFETY SIGNS DECALS...

Страница 47: ...2 1 CONTROLS...

Страница 79: ...3 1 OPERATION...

Страница 89: ...3 11 MEMO...

Страница 111: ...4 1 TRANSPORT...

Страница 115: ...4 5 TRANSPORT HOISTING THE MACHINE Three point suspension...

Страница 117: ...5 1 MAINTENANCE...

Страница 172: ...5 56...

Страница 173: ...6 1 TROUBLESHOOTING...

Страница 186: ...6 14...

Страница 187: ...7 1 SPECIFICATIONS...

Страница 189: ...7 3 MEMO...

Страница 190: ...7 4 SPECIFICATIONS MACHINE DIMENSIONS Canopy MACHINE DIMENSIONS...

Страница 192: ...7 6 SPECIFICATIONS Cab MACHINE DIMENSIONS...

Страница 194: ...7 8 SPECIFICATIONS OPERATING RANGES OPERATING RANGES...

Страница 196: ...7 10 MEMO...

Страница 198: ...7 12 SPECIFICATIONS Standard arm LIFTING CAPACITIES...

Страница 199: ...7 13 SPECIFICATIONS Standard arm LIFTING CAPACITIES...

Страница 200: ...7 14...

Страница 201: ...8 1 OPTIONS...