7-7

7.4 Maintenance and replacement period.

No.

Position

Items.

Period

1.

Oil filler points of the column

CC68

once per day.

2.

Oil filler points on top of the gearbox

CC68

once per day.

3.

Oil filler points in the right side of the gearbox.

CC68

once per day.

4.

Oil filler points in the left side of the gearbox.

CC68

once per day.

5.

Oil filler points of the spindle

XM2

once per day.

6

Replace oil for the speed reduction of the arm

elevating motor.

CC68

once per year.

7

Change oil inside of the gearbox.

CC68

once per year.

8

Chang the cutting fluids.

The cutting fluids

once per

month.

9

The arm transmit ion ball screw

XM2

Once per

month

A suitable Oil Type comparison:

ISO DIS-3498

SHELL

MOBIL

ESSO

CHINA

CC68

OMALA 68

MOBILGEAR 620

SPARTAN EP68

HD68

XM2

ALVANIA R2

MOBILUX 2

BEACON 2

#2

7.5 Waste disposition.

Please proceed waste disposition such as machine oil, iron filings, old machine or replaced

parts according to your country’s relevant legal regulation.

Содержание TPR1100

Страница 1: ...D E C 0 0 2 0 4 TAILIFT LTD 2006 RADIAL DRILLS TPR720A TPR820A TPR920A TPR1100 Operation Manual...

Страница 6: ...1 5 b 2 The rear view only for TPR 1100 C Oil filler position and Oil Drain outlet position Gearbox...

Страница 7: ...1 6 Arm elevating motor For TPR 720A TPR 820A TPR 920A Arm elevating motor For TPR 1100...

Страница 30: ...5 4 5 1 2 For TPR 1100 The front view of TPR 1100...

Страница 40: ...5 14 Examples of clamping using the universal clamp...

Страница 81: ...9 6 9 6 Electrical Circuit Diagram For TPR720A TPR820A TPR920A Standard...

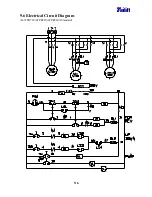

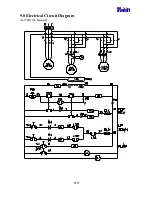

Страница 84: ...9 9 9 8 Electrical Circuit Diagram For TPR1100 Standard...