4

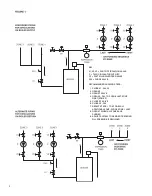

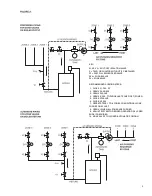

ACCEPTABLE MOTOR MOUNTING POSITIONS

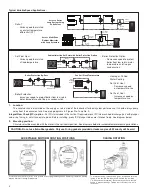

CASING ROTATION

To rotate the casing, remove the 4 motor screws and spin the

casing to the desired flow direction. Reattach the 4 screws

(

5

⁄

32

" allens wrench required). Be sure body gasket is seated

evenly to prevent leakage. Tighten motor screws to 34-42 in-

lbs torque.

Position electrical knockout at 6 o’clock position for best programming and LCD viewing orientation. Casing

may be rotated to change flow direction.

Across a Series

Loop System Using

Zone Valves

M

M

Return

Sensor

M

Across Multi-Zone

Radiant Manifolds

with Loop Actuators

iS

erie

s-R

B

C

A

B

C

A

M

M

M

M

M

M

M

M

Outdoor

Sensor

Boiler

Sensor

Supply

Sensor

Supply

Sensor

Return

Sensor

Boiler

Return Sensor

Boiler Protection By-Pass

Duct

Supply

Sensor

Fan Coil Fixed Temperature

Typical Variable Speed Applications:

Supply

Sensor

Boiler Return

Sensor

Mixing

Radiant Injection Set Point with Boiler Protection Option

• Delta-T

- Varies speed to maintain

a constant temperature

differential (∆T)

• Set Point Heat

- Varies speed to maintain

a fixed temperature

• Boiler Protection Option

- Decreases speed to protect

boiler from low return water

temperature and flue gas

condensation

• Boiler Protection

- Increases speed to protect boiler from low return

water temperature and flue gas condensation

• Heating or Chilled

Water Cooling

• Set Point Heat

- Decreases speed

on temperature rise

• Set Point Cool

- Increases speed on

temperature rise

1. Location:

The circulator can be installed on the supply or return side of the boiler but for best system performance, it should always pump

away from the expansion tank. See piping diagrams in Figures No.1 and No. 2.

Integral Flow Check (IFC

®

) option

- An IFC

®

is included in the carton. If required, press IFC into machined discharge port with plunger

and o-ring facing in, until it snaps into place. Before installing, press IFC plunger to be sure it moves freely. See diagram below.

2. Mounting position:

Circulator must be mounted with the motor in the horizontal position. See diagrams below for acceptable motor mounting orientations.

CAUTION: Do not use flat rubber gaskets. Only use O-ring gaskets provided or leaks may result. Warranty will be void.