33/70 |

FDS...EX

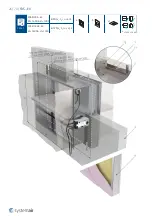

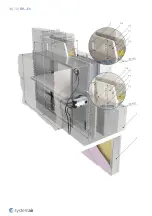

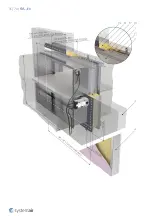

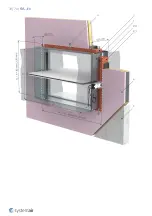

Installation 3 - Soft

Installation into a Soft Crossing with fire-resistive coating

With this installation, we recommend using flexible connections (see accessory FCR) due to thermal expansion of

connected ducts during fire. Install the compensator so that the flexible part has a minimum distance of 50 mm from

the edge of a damper‘s blade in an open position.

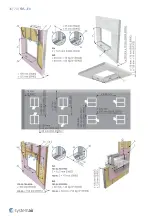

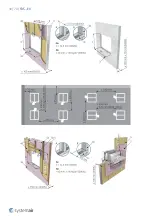

1. The supporting construction opening must be prepared as depicted. Opening surfaces must be even and cleaned

off. The flexible wall opening must be reinforced as per the standards for plasterboard walls. The opening

dimensions are driven by the nominal dimensions of the damper with added clearance. For rectangular dampers,

the opening will have the dimensions of W1 and H1.

2. Prepare mineral wool installation segments (F5) with a thickness of the opening height. First apply a suitable fire-

resistive coating (F6) onto the damper at the place of its future placement, assemble and glue the filling of the

future installation with the same fire-resistive coating. After the fire-resistive coating has dried, the damper and

the filling are ready for installation.

3. Apply the same fire-resistive coating (F6) onto the internal surface of the wall opening. Also apply the fire-resistive

coating on the external surface of the filling glued on the damper surface. Immediately after the fire-resistive

coating is applied, place the damper into the wall opening. The damper blade must be located in the supporting

structure.

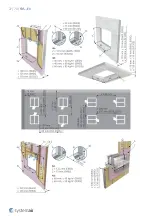

4. After inserting the damper into the opening and fixing it using the bendable hangers and suitable screws (F1),

apply the same fire-resistive coating (F6), at least 2 mm thick and 100 mm wide, on the exposed filling and wall

edges evenly from both sides. Do not apply this layer in the place where the mechanism is located, inspection

openings and manufacturer labels.

5. It is necessary to fix the dampers installed in a wall using four steel L-profiles (F7) from above and below. Anchor

the profiles to the wall on each end using at least one screw (F1) and self-drilling screws (F8) against the damper

with gaps of a maximum of 200 mm.

6. Dampers installed into a ceiling need to be fixed onto the ceiling using two steel L-profiles (F7) from above (applies

for all types). Anchor the profiles to the ceiling on each end using at least one screw (F1) and self-drilling screws

(F8) against the damper with a maximum of 200 mm gaps.

7. If needed, uncover and clean the damper after installation.

8. Check the damper’s functionality

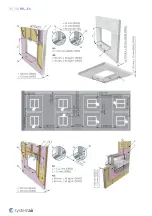

Installation - Standard Distances

According to standard EN 1366-2, the minimum distance from the wall or ceiling to the damper body is 75 mm. For

multiple crossings through a fire-resistive wall the minimum distance between two damper bodies is 200 mm. This

applies to distances between the damper and a nearby foreign object crossing the fire-resistive wall.

Installation - Smaller Distances

The distance between 2 individual fire dampers can be reduced to 60 mm, measured from surface to surface of the

housing and the distance between the surface of the damper installed in the duct and the adjacent supporting

construction (wall/floor) can be reduced to 40 mm.

Installation in a Wall thinner than tested

Installation in a thinner wall is allowed under the condition that an additional layer/layers of fire protective board are

fixed to the surface of the wall in order to achieve the same length of damper penetration seal as was tested. The

minimum width of added boards around the damper is 200 mm. In addition, the alternative thinner wall should be

classified in accordance with EN 13501-2:2007 + A1: 2009 for the fire-resistance required for product application. For

a protruding wall, the additional layers must be fixed on the steel supporting construction of the wall.

Содержание FDS-3G EX Series

Страница 1: ...FDS EX Atex Fire Damper ...

Страница 8: ...8 70 FDS EX Product parts ...

Страница 27: ...27 70 FDS EX ...

Страница 30: ...30 70 FDS EX ...

Страница 31: ...31 70 FDS EX ...

Страница 35: ...35 70 FDS EX ...

Страница 36: ...36 70 FDS EX ...

Страница 39: ...39 70 FDS EX ...

Страница 40: ...40 70 FDS EX ...

Страница 43: ...43 70 FDS EX 5 1 On Out FDS EI90S EX W 1600 H 1000 EI 90 ve i o S a b ...

Страница 44: ...44 70 FDS EX ...

Страница 48: ...48 70 FDS EX ...

Страница 49: ...49 70 FDS EX ...

Страница 52: ...52 70 FDS EX ...

Страница 53: ...53 70 FDS EX ...

Страница 57: ...57 70 FDS EX 5 4 On Out FDS 3G EX 100 100 1200 800 EI 60 ve i o S a b ...

Страница 58: ...58 70 FDS EX ...

Страница 59: ...59 70 FDS EX ...

Страница 63: ...63 70 FDS EX 7 Multi FDS EI90S EX W 1600 H 1000 EI 90 ve i o S b ...

Страница 70: ...Systemair DESIGN 2021 04 27 Handbook_FDS_EX_en GB ...