SS-400-000

4

I56-3065-000R

NOTE:

This procedure should only be used in an emergency, and

it is not intended as a permanent substitute for ordering the cor-

rect length tubes.

Step 6. Field Wiring

Wiring Installation Guidelines

All wiring must be installed in compliance with the local codes

having jurisdiction. Proper wire gauges should be used. The con-

ductors used to connect smoke detectors to control panels and ac-

cessory devices should be color-coded to prevent wiring mistakes.

Improper connections can prevent a system from responding

properly in the event of a fire.

For signal wiring, (the wiring between interconnected detectors

or from detectors to auxiliary devices), it is recommended that

single-conductor wire be no smaller than 16 gauge (1.5 square

mm), and that two- or three-conductor wire be no smaller than

18 gauge (1.0 square mm). The last foot or so of conduit should

be flexible steel conduit (available in electrical supply houses)

which facilitates easier installation and puts less strain on the

conduit holes in the housing. Solid conduit connections may be

used if desired.

Smoke detectors and alarm system control panels have specifi-

cations for allowable loop resistance. Consult the control panel

manufacturer’s specifications for the total loop resistance allowed

for the particular model control panel being used before wiring

the detector loop.

Wiring Instructions

The 7251DH is designed for easy wiring. The housing provides a

terminal strip with clamping plates. Wiring connections are made

by stripping approximately

1

/

2

˝ of insulation from the end of the

wire, sliding this bare end under the plate, and tightening the

clamping plate screw.

Step 7. Install the Filters

Most duct installations are subject to dust accumulation. System

filters remove a large percentage of this contamination, but

cannot remove all of it. Dust inside the duct detector causes

problems. First, very fine particles of dust can enter the detector

sensing chamber and cause the unit to go into alarm. Second,

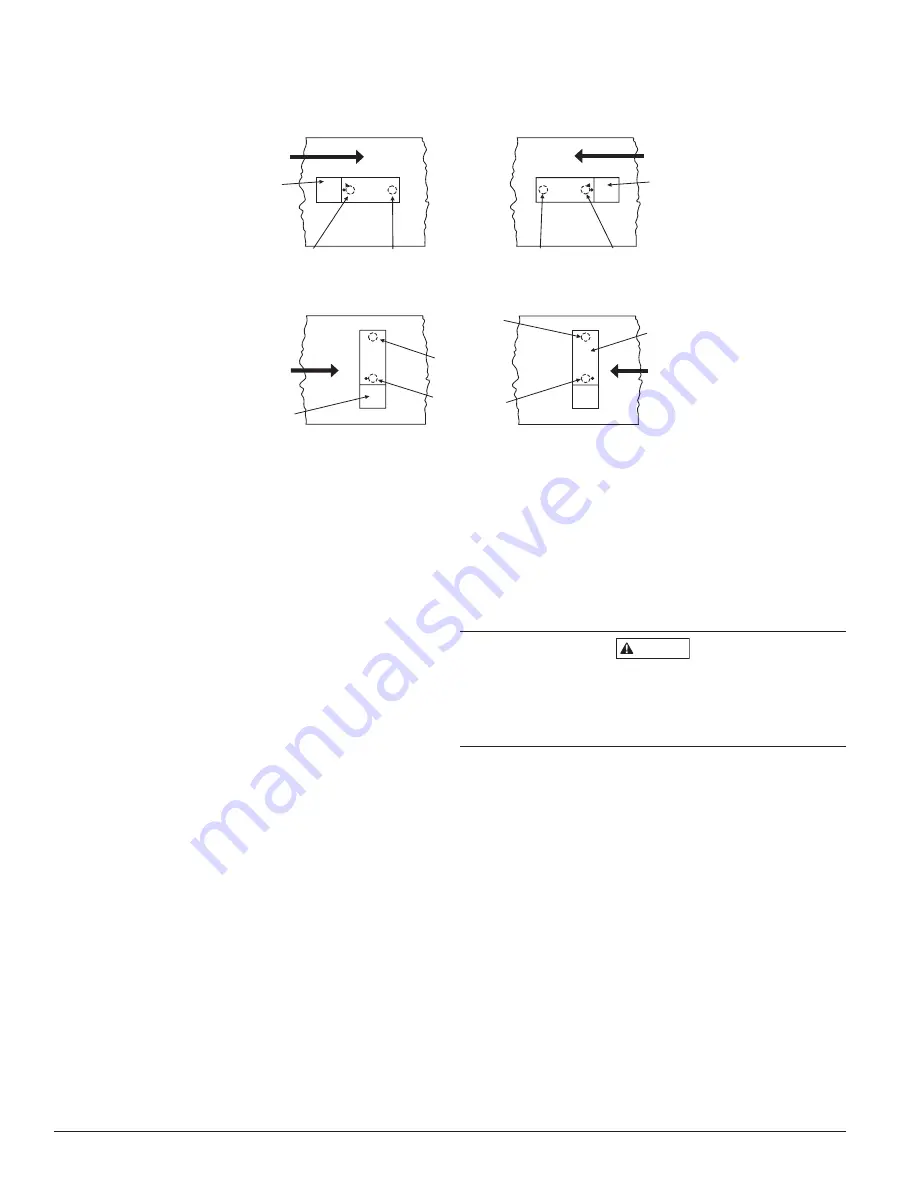

AIR FLOW

DIRECTION

DETECTOR

HOUSING

DOTS INDICATE POSITION OF

SAMPLING TUBE HOLES

AIR FLOW

DIRECTION

DETECTOR

HOUSING

INLET

TUBE

EXHAUST

TUBE

AIR FLOW

DIRECTION

EXHAUST

TUBE

INLET

TUBE

INLET

TUBE

EXHAUST

TUBE

DETECTOR

HOUSING

AIR FLOW

DIRECTION

EXHAUST

TUBE

INLET

TUBE

DETECTOR

HOUSING

A.

B.

C.

D.

HORIZONTAL MOUNTING OF HOUSING

VERTICAL MOUNTING OF HOUSING

Figure 5. Tube mounting configurations with varying air flow direction and orientation of detector housing.

Vertical as well as horizontal mounting is acceptable:

H0109-00

the accumulation of dust and dirt necessitates a more frequent

periodic cleaning schedule, which can result in substantial cost

and/or down time.

Disposable sampling tube filters can greatly reduce the nuisance

alarms caused by dust, and can also significantly extend the

maintenance interval. To install the sampling tube filters, simply

push the filter adapter into the exhaust tube, and then push the

filter onto the adapter tube on the left, as shown in Figure 6. Then

install the other filter over the end of the inlet sampling tube.

CAUTION

Filters require periodic cleaning or replacement, depending on the

amount of dust and dirt accumulated. Visually inspect the filters

at least quarterly; inspect them more often if the dust accumula-

tion warrants it. Replacement filters can be ordered from System

Sensor (exhaust tube/intake tube filter P/N F36-05-00).

The filters do not substantially affect smoke performance under

normal conditions. There is very little restriction of smoke entry

even when up to 90% of the filter is clogged. Visual inspection

is usually adequate to determine whether the filters should be

replaced because such a high percentage of contamination is re-

quired to affect performance.

However, if further testing is desired, a Dwyer Model 460 (or

equivalent) Differential Pressure Gauge may be used. Simply com-

pare the differential pressure readings with and without the filters

attached. There should be little or no difference. If the difference

exceeds 10%, replace the filters. In no case, however, should the

pressure differential be less than 0.01 inches of water or greater

than 1.2 inches of water.

Step 8. Perform Detector Check

8.1 Air Flow

1. To verify sufficient sampling of ducted air, use a manometer

to measure the differential pressure created from air flow

across the sampling tubes. The pressure should measure no

less than 0.01 inches of water and no greater than 1.20 inches

of water.

firealarmresources.com