3

screwdriver counterclockwise will widen the air gap (increasing the current draw).

To adjust the air gap to a proper setting, turn the knob on the front of the jogger to a "100" dial setting. Then

turn the core clockwise until a striking condition exists, then immediately turn the screwdriver counterclockwise,

just until the striking stops.

Check the current draw of the jogger using an a-c ammeter. If a clamp-on type ammeter is used the reading

must be multiplied by 1.7. Do not exceed a current draw of 1.0 amps.

When the proper air gap has been achieved (indicated by the current draw), lock the core in place by turning

the socket head cap screw on the bottom of the jogger. The jogger is now ready for further operation.

TROUBLE SHOOTING

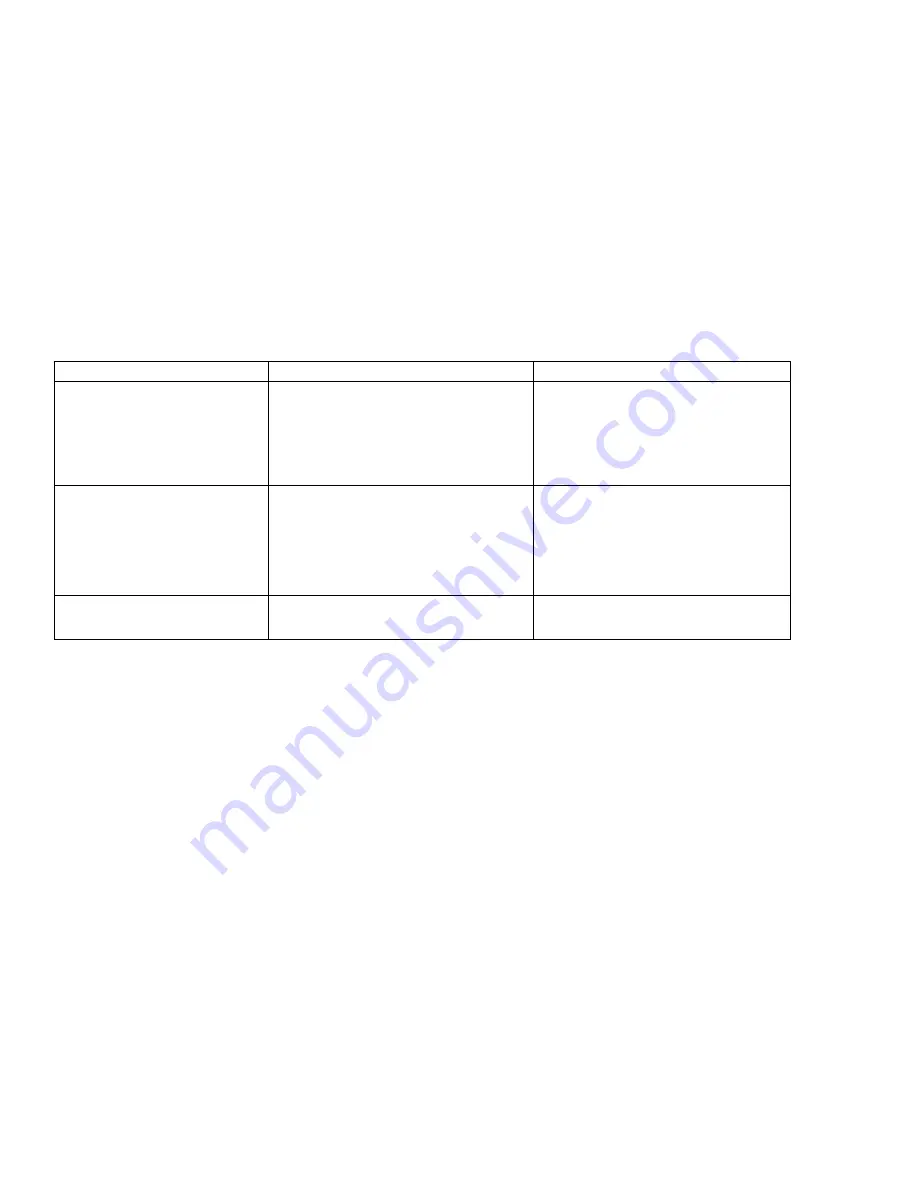

PROBLEM

CAUSE

CORRECTION

Unit does not operate

Defective control board

* Replace

Shorted wiring, loose

Repair

connection, no power to unit

Unit operates, will not

Defective Control Board

*Replace

vibrate

Defective leaf springs

*Replace

Unit In contact with rigid

object or adjacent surface

Isolate unit

Excessive noise

Armature and magnet

Adjust air gap

assemblies making contact

*Replace only with parts supplied, or recommended, by Syntron Material Handling, LLC.