4

INTRODUCTION

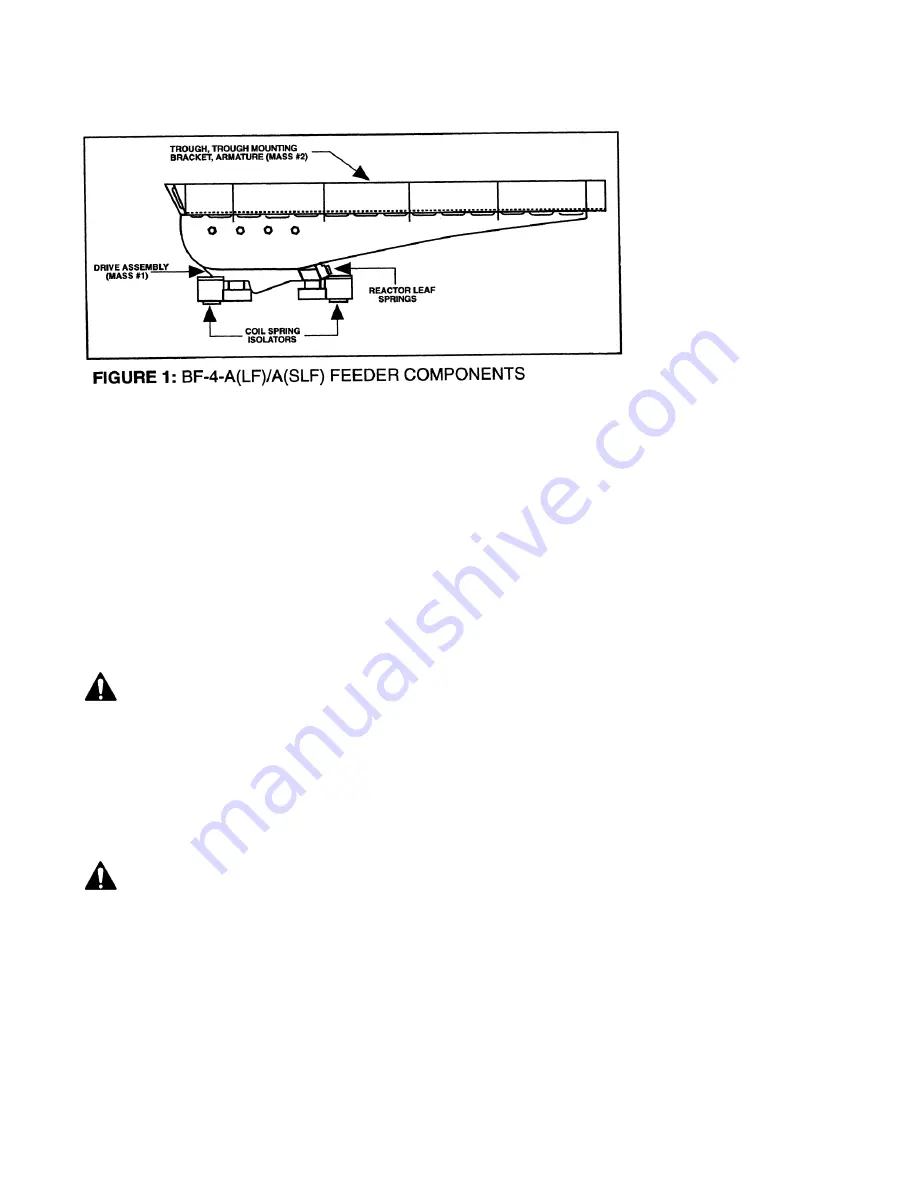

The Syntron® BF-4-

ALF/ASLF (low

frequency)

Electromagnetic Feeder

is a dynamically

balanced, two-mass

isolated vibrating system,

consisting of a trough and

trough mounting bracket,

coupled to the drive

assembly by leaf springs.

The BF-4 feeder can

accommodate a large

range of trough sizes with

a

maximum trough length of 120 inches (3048 mm), and a maximum feed rate of 50 feet (15.24 m) per

minute.

Because of its unique design, the BF-4 is ideal for feeding various types of products such as snacks and

vegtables, to packaging and processing equipment such as multi-head weigh scales and filling machines.

The BF-4 has along trough overhang that reduces product reduces product degradation by allowing the

feeder discharge to be positioned as close to the scale or transfer point as possible, minimizing product

drop.

INSPECTION AND STORAGE

WARNING: Do not drop the control or feeder; the force of the impact may damage the coponents.

Upon receipt, carefully unpack and inspect the feeder for any damage that may have occurred during

shipment. If damage is found, contact the shipping carrier and Syntron Material Handling immediately.

If the feeder is to be stored for an extended period of time, store it indoors, in its original shipping carton,

in a clean, dry area protected from extreme heat. Plug all holes to prevent dirt, rodents and insects from

entering. SMH advises placing a corrosion preventive inside the control box. Apply oil or rust preventive

to the hardware, and completely cover the unit with a waterproof covering.

WARNING: Do not oil the spring assemblies. Oiling the spring assemblies will destroy the

clamping effect of the spring pads against one another. No lubrication is required for electromagnetic

feeders.

THEORY OF OPERATION