1-7-4

T5307EA

5. V. Size Adjustment

Purpose: To obtain correct vertical height of screen

image.

Symptom of Misadjustment: If V. Size is incorrect,

vertical height of image on the screen may not be

properly displayed.

1. Enter the Service mode. (See page 1-4-1.)

Press "9" button on the remote control unit and

select V-S Mode. (Press "9" button then display will

change to V-P and V-S).

2. Input monoscope pattern.

3. Press CH

o

/

p

buttons on the remote control unit

so that the monoscope pattern is 90

±

5% of display

size and the circle is round.

6. V. Shift Adjustment

Purpose: To obtain correct vertical position of screen

image.

Symptom of Misadjustment: If V. position is incor-

rect, vertical position of image on the screen may not

be properly displayed.

1. Enter the Service mode. (See page 1-4-1.)

Press "9" button on the remote control unit and

select V-P Mode. (Press "9" button then display will

change to V-P and V-S).

2. Input monoscope pattern.

3. Press CH

o

/

p

buttons on the remote control unit

so that the top and bottom of the monoscope pat-

tern are equal to each other.

7. H. Shift Adjustment

Purpose: To obtain correct horizontal position and

size of screen image.

Symptom of Misadjustment: Horizontal position and

size of screen image may not be properly displayed.

1. Enter the Service mode. (See page 1-4-1.)

Press "8" button on the remote control unit and

select H-P Mode.

2. Input monoscope pattern.

3. Press CH

o

/

p

buttons on the remote control unit

so that the left and right side of the monoscope pat-

tern are equal to each other.

4. Turn the power off and on again.

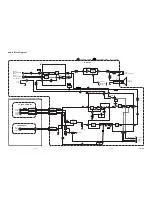

8. Cut-off Adjustment

Purpose: To adjust the beam current of R, G, B, and

screen voltage.

Symptom of Misadjustment: White color may be

reddish, greenish or bluish.

Test point

Adj. Point

Mode

Input

---

CH

o

/

p

buttons

---

Monoscope

Tape

M. EQ.

Spec.

---

Pattern Generator

90

±

5%

Test point

Adj. Point

Mode

Input

---

CH

o

/

p

buttons

---

Monoscope

Tape

M. EQ.

Spec.

---

Pattern Generator

90

±

5%

Test point

Adj. Point

Mode

Input

---

CH

o

/

p

buttons

---

Monoscope

Tape

M. EQ.

Spec.

---

Pattern Generator

90

±

5%

Test point

Adj. Point

Mode

Input

---

Screen-Control

Ext.

Black

Raster /

White

Raster

Tape

M. EQ.

Spec.

---

Pattern Generator

See Reference

Notes below

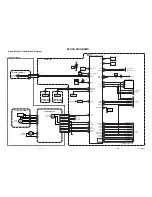

Figure

PATTERN GENERATOR

EXT. INPUT

Fig. 3

Содержание SRC2213

Страница 20: ...1 6 2 T5307DC Fig 1 S 1 S 1 1 REAR CABINET S 1 S 1 S 1 S 1 Fig 2 ...

Страница 21: ...1 6 3 T5307DC S 2 S 4 S 3 S 3 S 4 S 4 S 4 S 4 S 2 S 2 S 2 2 TRAY CHASSIS 4 MAIN CBA 3 DECK UNIT Fig 3 ...

Страница 22: ...1 6 4 T5307DC Fig 4 CRT CBA S 5 S 5 S 5 S 5 ANODE CAP 5 CRT ...

Страница 25: ...1 6 7 T7308DC Fig 1 ANT S 1 S 1 1 REAR CABINET S 1 S 1 S 1 S 1 Fig 2 ...

Страница 26: ...1 6 8 T7308DC S 2 S 4 S 3 S 3 S 4 S 4 S 4 S 4 S 2 S 2 S 2 2 TRAY CHASSIS 4 MAIN CBA 3 DECK UNIT Fig 3 ...

Страница 27: ...1 6 9 T7308DC Fig 4 S 5 S 5 S 5 S 5 5 CRT CRT CBA ANODE CAP ...

Страница 88: ...Packing SRC2213 SRC22134 FRONT X 4 X 3 X 2 TAPE X 1 S 1 X 5 S 4 S 6 S 2 S 3 S 3 S 2 3 1 5 T5307PEX ...

Страница 89: ...Packing SRC22194 X 1 S 1 S 4 S 3 S 3 S 2 TAPE TAPE X 4 X 3 X 2 S 6 S 14 FRONT 3 1 6 T7308PEX ...

Страница 108: ...Printed in Japan 2002 02 20 HO SRC2213 SRC22134 SRC22194 T5307UH 8UJ 7308UJ ...