17

•

Sanding stock wider than the drum

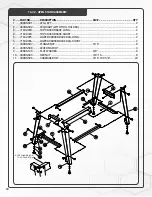

When sanding stock wider than the drum the fast lever

will be very useful (see picture). Wide stock requires

extra space between the drum and conveyor on the

outboard (left) edge. The extra space prevents overlap

ridge lines from developing along the part that extends

beyond the drum. Adjust the fast lever 45 degrees from

the vertical position to slightly shift the drum position

without changing initial drum alignment. Before san-

ding always test on a scrap piece. If a line or ridge is

still visible, adjustments can be made to the drum

alignment. Always return the lever to the upright posi-

tion when wide stock sanding is completed.

Note: The fast lever raises the inboard side of the table .003. Upon first use, you may notice that the conveyor table bolts

have been set be too tight at the factory not allowing the Fast Lever to be moved. This was done to keep the unit secure for

shipping. The conveyor table bolts may need a slight loosening to allow for proper Fast Lever movement. Never tighten the

table bolts all the way. Tighten the bolts enough to still allow the fast lever to be moved between the up and down positions.

•

Sanding multiple pieces simultaneously

When sanding multiple pieces at once, make sure to stagger or step the pieces across the width of the conveyor

belt. This position provides better contact with the tension rollers. It is best to only process multiple pieces that

are all of a similar thickness. If there is a thickness difference the thinner pieces may not come in contact with

the tension rollers and may slip on the conveyor belt

•

Sanding Imperfect or Tall Stock

To avoid bodily injury take special care when sanding stock that is twisted, bowed or otherwise varied in thickness

from end to end. If possible support such stock as it is being sanded to keep it from slipping or tipping. Use extra

roller stand, assistance from another person, or hand pressure on the stock to minimize potentially hazardous

situations. When sanding high or tall stock special attention is necessary to prevent tipping or slippage. Extra

care may be needed as the stock exits the machine.

•

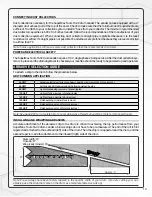

Stock Feeding Position and Angle

Positioning the stock at an angle will allow the most effective stock removal and least loading on the abrasives.

Feeding stock straight through yields the widest sanding capacity and least noticeable scratch pattern. Some

pieces because of their dimensions will need to be fed into the sander at a 90-degree angle, which will be per-

pendicular to the drum. However, even a slight offset angle of the stock can provide for more effective sanding.

Final pass sanding should be done following the grain pattern.

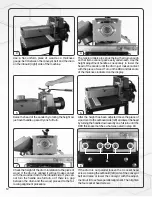

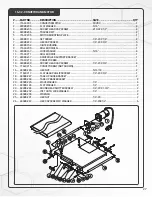

TENSION ROLLER PRESSURE

The tension roller pressure is factory set and should

be adequate. However, the pressure of each roller can

be adjusted as needed.

To increase the tension turn the tension adjusting

screw clockwise 1/4 revolution at a time. To decrease

tension turn the adjusting screw counter-clockwise

1/4 revolution at a time (see opposite picture).

Note: Too little pressure can result in slippage of stock on

conveyor belt or kick-back. Too much tension can cause

snipe when drum sanding.

Содержание 16-32

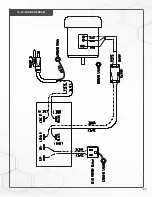

Страница 23: ...23 16 32 WIRING DIAGRAM...

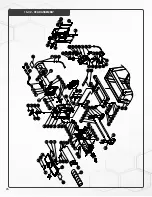

Страница 26: ...16 32 HEAD ASSEMBLY 26...

Страница 29: ...NOTES 29...

Страница 30: ...P 1 888 454 3401 F 1 651 454 3465 SuperMaxTools com sales SuperMaxTools com...