16

4-4. Trial run (Pedal operation)

[ Caution ]

·

Make sure not to touch or press down parts that are operating or moving during operation. Failure to follow the safety rules

may result in physical injuries or mechanical damages.

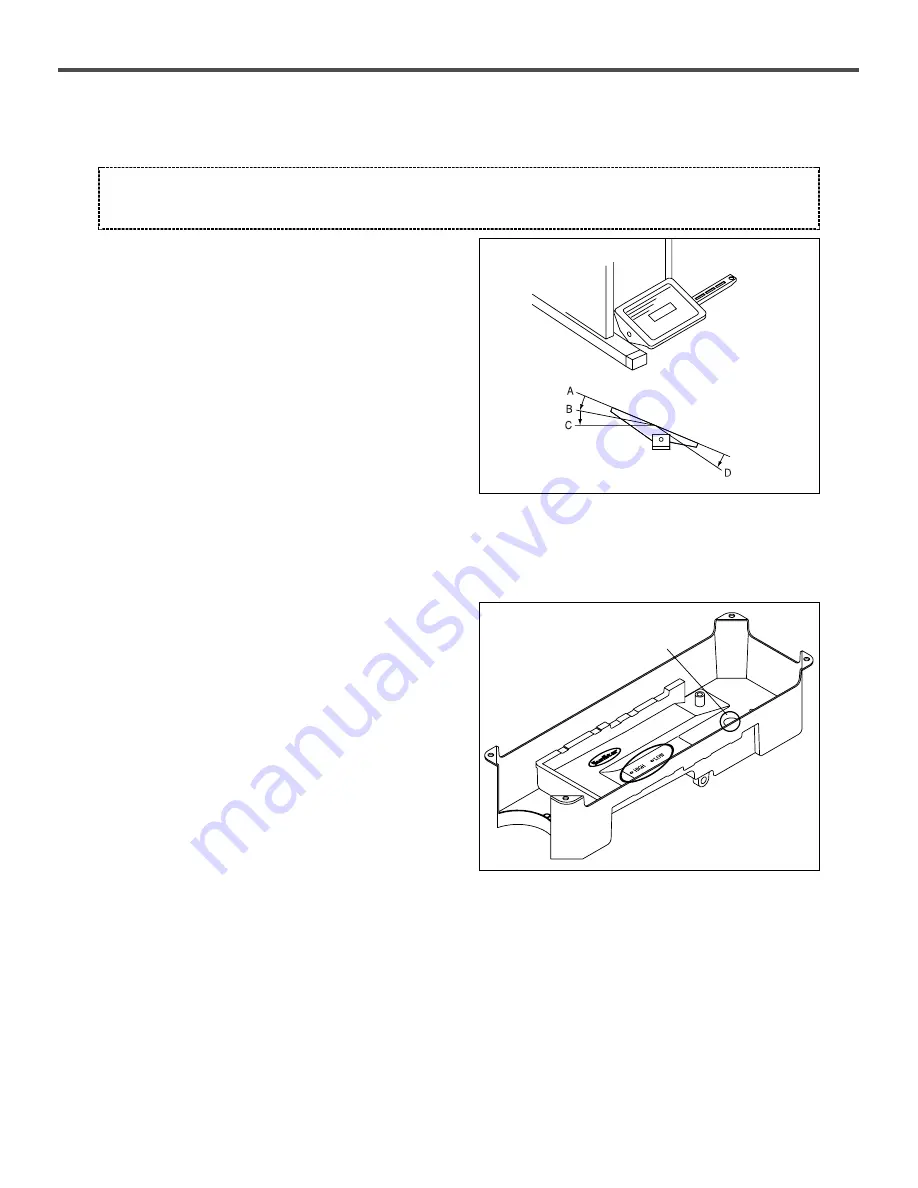

[ Figure 18 ]

1. Press pedal lightly to the position of B to check if the

machine is operating low-speed sewing.

2. Press pedal to the position of C to check if the machine is

operating high-speed sewing.

3. Press pedal backward and forward. And then put the pedal at

neutral position of A to check if needle stops lower than the

upper surface of needle plate.(in case that needle down stop

is set)

4. When pressing pedal to the position of D(or pressing pedal

the position of to D and then replacing pedal to the position

of A), needle will stop higher than the upper surface of

needle plate after trimming.

[ Figure 19 ]

4-5. Installation (KM-2310 Series)

1. Installing magnet for chip (metal powder) removal

1) Take out the magnet for chip (metal powder) removal

from the accessory box and attach it to

①

inside the oil

fan.

※

If the sewing machine is operated without the magnet, it

may cause abnormalities in the sewing machine. Use of

the magnet can improve machine durability.

2. Lubricant supply to oil fan

1) Fill the oil fan with lubricant up to the “HIGH” mark.

2) Use either the oil for SunStar industrial sewing machines

or Shell

’

s Tellus C10 as lubricant.

3) When the lubricant level falls to “Low”, the oil fan shall

be refilled with lubricant until it reaches the “HIGH”

mark again.

4) Replace lubricant every two weeks.

①

Содержание KM-2300

Страница 2: ......