P.13

on a good sunny day. Contact your solar con-

tractor if the charged collector loop pressure

exceeds this threshold.

Your SolaRay solar water heating system must be

charged and the fluid quality maintained by an

experienced contractor. If the system is drained

during the winter, or you notice a significant drop

in collector loop pressure, contact your installa-

tion contractor immediately for service. The gly-

col HTF provides the freeze protection for your

system and must be properly maintained. An

experienced contractor should periodically check

the HTF fluid quality.

4.11.6 Dowfrost HD HTF

To ensure maximum effectiveness for corro-

sion protection, the glycol inhibitor package

is designed for a minimum 25-30 percent

concentration of glycol in water.

Table 4

shows the concentrations of Dowfrost HD

required to provide freeze and burst protection at

various temperatures. Use the mixture most

appropriate for your climate. Do not use a high-

er glycol to water concentration than necessary,

as this will adversely impact the relative heat

transfer efficiency of the solution.

Generally, for an extended margin of protection,

you should select a temperature that is at least

5°F lower than the expected lowest ambient

temperature. These figures are examples only

and should not be regarded as specifications. As

use conditions are not within our control, neither

SunEarth nor Dow Chemical guarantees that

freeze damage may not occur at temperatures

other than shown.

Water used to dilute the HTF must meet certain

minimum standards for purity. Impurities in the

dilution water can increase metal corrosion,

reduce the effectiveness of corrosion inhibitors,

increase inhibitor depletion rate, and cause the

formation of scale and other deposits on the heat

exchanger's internal heat transfer surfaces.

Distilled or deionized water is required.

The HTF pH level must be maintained

between 8 and 10 to minimize corrosion and

glycol oxidation in the piping system.

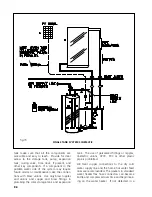

5) SYSTEM START-UP PROCEDURES

Throughout the installation procedures outlined

in Section 4 above, emphasis has been placed on

the correct procedures for plumbing and wiring

the components, checking for plumbing leaks,

pressurizing the collector glycol loop, and elimi-

nating any trapped air that can impact fluid qual-

ity and pump performance. Having completed

these tasks it is time to start up your SolaRay

solar water heating system.

When the glycol loop has been fully charged and

the pressure is around 25 psi (check the pressure

gauge, No. 7) turn the circulating pump toggle

switch to the "on" position. Your system is now

set for automatic operation. Remember that the

speed at which your pump will circulate is direct-

ly related to the intensity of the sunlight. If your

installation is completed on a cloudy or overcast

day the pump may run very slowly.

Adjust the valve settings in accordance with

Section 6 below.

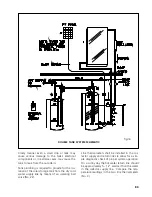

6) THREE MODES OF SYSTEM OPERATION

Both single and double tank Solaray systems are

designed to accommodate three separate modes

of operation. Your solar water heating system

can, (1) provide 100% solar operation during

good weather, or (2) serve as a preheater to your

electric water heater adding solar energy when

and as available, or (3) completely bypass the

solar collector loop and solar storage tank and

run 100% on utility power during inclement

weather.

Single Tank Operating Instructions:

6.1 100% Solar Operation:

Turn off the circuit breaker to your solar storage

tank. If a mechanical water heater time switch

has been installed, turn the switch to the "off"

position and remove the trippers from the face of

the switch.

6.2 Solar Preheat

Leave the circuit breaker to your solar storage

tank on and set the tank thermostat to the low-

est acceptable temperature setting. The electric

resistance heating elements will come on only