P.12

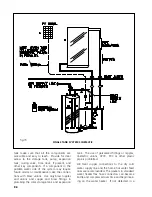

upper charge valve and the water is running,

open the lower purge/drain valve (No. 11) and let

the water run out until it is free of impurities or

debris that might have entered the piping as the

components were plumbed. Run the water long

enough to eliminate any air bubbles that may be

trapped in the system.

Close the lower purge/drain valve. The collector

loop now has been subjected to city pressure and

the pressure gauge should read somewhere in

the range of 50 - 75 PSI in most cases (No. 7).

Make a final inspection of the collector plumbing

connections to ensure that there are no leaks

anywhere in the collector loop piping.

4.11.3 After you have determined the integrity

of the entire piping system turn on the circulat-

ing pump. Flip the toggle switch to the "on"

position. If there is insufficient sun to run the

pump, contact the pump wires directly to the

positive and negative poles of a 12 volt battery or

power source. Run the pump for a full five min-

utes and carefully check to ensure there is prop-

er fluid flow and that all the air has been purged

from the solar collector glycol loop. An inexpen-

sive flow meter such as manufactured by Blue

White Industries or Letro is recommended as an

optional system component. A flow meter

allows you to monitor and adjust the flow rate

through the piping and also to visually inspect

the HTF fluid quality.

Flip the toggle switch to the "off" position and

proceed to the next step.

4.11.4 Mix the Dowfrost HD propylene glycol

and distilled water mixture in accordance with

Table 4 and Table 5 in a large clean bucket. You

will need a second empty bucket as well. The

charging process also will require a low flow

diaphragm pump (Flojet or equal) to fill and pres-

surize the collector loop.

Connect the discharge side of the pressure pump

to the upper charge faucet (No. 9) Place the

pump suction side hose in the glycol solution.

Close the isolation ball valve (No. 10) and con-

nect a second hose to the lower charge faucet

(No. 11). Place the other end of the hose in the

empty bucket.

Open the upper charge faucet and allow the

pressure from the expansion tank to push the

water in the glycol loop back to prime the pres-

sure pump. When the hose in the bucket con-

taining the glycol mixture stops bubbling you

may begin charging the collector loop with gly-

col.

With both charge faucets now open, run the

Flojet pressure pump until the pinkish glycol mix-

ture begins flowing into the empty bucket.

Quickly switch the hose from the empty/return

bucket to the bucket containing the glycol mix-

ture. Continue to circulate the fluid using the

pressure pump until the bubbling has stopped

and the air has been purged.

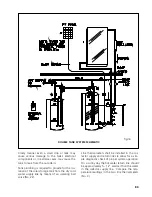

4.11.5 After charging the collector loop, shut

the lower charge faucet and let the pressure

pump drive up the loop pressure to the appropri-

ate level (Generally in the range of 25 PSI). To

more accurately calculate the proper pressure

measure the height of the solar collector above

the solar storage tank and divide this number by

2.31. Then add 20 PSI to this number. As a word

of caution, the pressure in the glycol loop should

not exceed 45 PSI when the system is operational

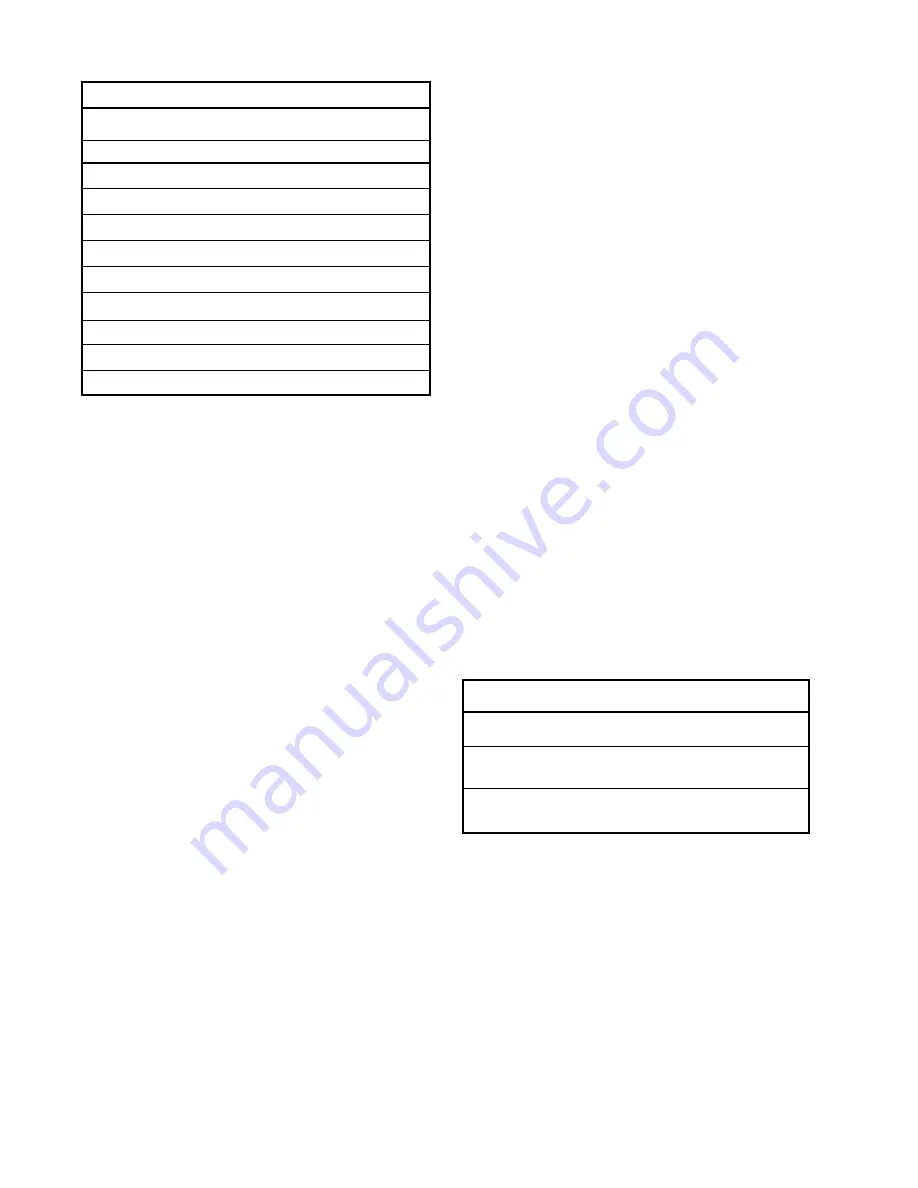

Table 5

Total Collector Loop Fluid Capacity In Gallons*

1 Collector System

4 Gallon

2 Collector System

5 Gallons

Table 4

Percent (volume) Glycol Concentration Required

Temperature F

For Freeze Protection

For Burst Protection

20

18%

12%

10

29

20

0

36

24

-10

42

28

-20

46

30

-30

50

33

-40

54

35

-50

57

35

-60

60

35

* Assumes a total 100’ pipe run using 3/4" Type

M hard copper tubing. The Rheem/Ruud heat

exchanger has a 2.2 gallon fluid capacity.