4-2

SECTION 4 – MAINTENANCE

DAILY MAINTENANCE

1. Grease lift arms, walking tandem assemblies, casters and hitch pivot.

2. Check all hydraulic components for leaks.

3. Check tightness of all wheel bolts.

PERIODIC MAINTENANCE

1. Tillage Hub Bearings: Every 50 hours add four strokes of grease to hub bearing. USE

ONLY NLGI #2 grease.

2. Repack wheel bearings and check tightness (See Page 6-32).

3. Check tire air pressure (See specification page 5-2).

4. Check tightness of trip assembly hardware as explained under “Maintenance for after

the first day and week of operation” (Page 4-1).

5. Check tightness of all hardware. Pay special attention to the hitch bolts and all pivot

retaining bolts.

6. Check machine for damaged or worn parts. Replace as needed.

STORAGE

1. Clean and remove all excessive dirt and grease from coulter-chisel.

2. Grease all zerks.

3. To prevent rusting, repaint any areas that have been worn, chipped or scratched.

4. Retract cylinders when possible. Apply grease* to any exposed part of cylinder shafts.

*NOTE:

Before returning machine into service, all grease must be removed from cylinder

shafts to prevent damage to seals.

Содержание CoulterChisel CC2815

Страница 6: ...NOTES iv ...

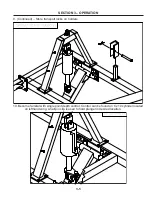

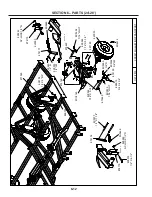

Страница 65: ...2 53 SECTION 2 INSTALLATION OF SHANKS AND COULTER GANGS ...

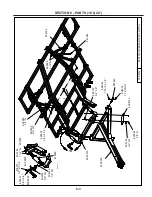

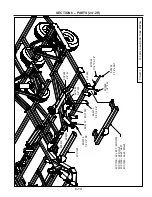

Страница 126: ...6 26 SECTION 6 PARTS ...

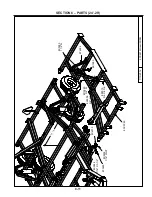

Страница 128: ...6 28 SECTION 6 PARTS ...

Страница 144: ...6 44 SECTION 6 PARTS NOTES ...