1600C LP USER MANUAL

SECTION 2

28

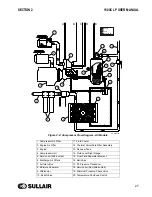

2.6

COMPRESSOR DISCHARGE

SYSTEM, FUNCTIONAL

DESCRIPTION

Refer to

. The Sullair compressor unit

discharges compressed air/fluid mixture into the

receiver tank.

The receiver tank has three functions:

1. It acts as a primary fluid separator.

2. Serves as the compressor fluid storage

sump.

3. Houses the final fluid separator.

The compressed air/fluid mixture enters the receiver

tank and is directed against the tank side wall. By

change of direction and reduction of velocity, large

droplets of fluid separate and fall to the bottom of the

receiver tank. The fractional percentage of fluid

remaining in the compressed air collects on the

surface of the final separator element as the

compressed air flows through the separator. As more

and more fluid collects on the element surface, the

fluid descends to the bottom of the separator. A

return line (or scavenge tube) leads from the bottom

of the separator element to the inlet region of the

compressor unit. Fluid collecting on the bottom of the

separator element is returned to the compressor by

the pressure difference between the area

surrounding the separator element and the

compressor inlet. An orifice (protected by a strainer)

is included in this return line to help assure proper

flow.

The receiver tank is code rated. A minimum

pressure/check valve, located downstream from the

separator, helps assure a minimum receiver pressure

during all conditions. This pressure is necessary for

proper air/fluid separation and proper fluid

circulation.

A minimum pressure/check valve at the outlet of the

receiver is installed to prevent compressed air in the

service line from bleeding back into the receiver on

shutdown when the compressor is being run in

parallel with other compressors tied to a large air

system.

Fluid is added to the receiver tank via a capped fluid

filler. A fluid level gauge glass enables the operator

to visually monitor the receiver tank fluid level.

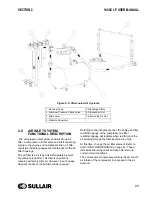

2.7

AFTERCOOLED AIR SYSTEM,

FUNCTIONAL DESCRIPTION

Refer to

. The purpose of the aftercooled

air system is to operate the air compressor in

conditions when compressed air temperatures are

required to be 10 to 25

°

F (5 to 13

°

C) over ambient

temperature. Two discharge valves are provided on

all aftercooled compressor models. One valve is

labeled standard air and one valve is labeled

aftercooled air. Closing the standard air (non-

aftercooled) valve completely forces the air flow from

the receiver tank to the aftercooler. The ambient air,

which is drawn through the aftercooler by the engine

fan, cools the compressed air as it passes through

the aftercooler core. Cooled air enters the moisture

separator where condensation is removed from the

cooler air and discharged. This condensation does

carry some oil and it should be disposed of properly

in accordance with local regulations. A condensation

drain port is located in the frame on the front of the

machine for convenience of condensate removal.

This drain port should never be plugged or closed off

in any way. From the moisture separator the

compressed air goes through the discharge filters (if

equipped) and on to the service valve.

WARNING

DO NOT remove caps, plugs, and/or other

components when compressor is running

or pressurized. Stop compressor and

relieve all internal pressure before doing so.

NOTE

Aftercooled system should not be operated

in ambient conditions below 32°F (0°C). If it

is necessary to operate in these conditions,

Sullair can supply optional equipment to

accommodate this requirement. To operate

in the non-aftercooled mode, close the

aftercooler service valve completely and

open non- aftercooled valve.

Содержание 02250175-949 R01

Страница 2: ......

Страница 20: ...SECTION 1 20 ...

Страница 30: ...1600C LP USER MANUAL SECTION 2 30 2 9 PIPING INSTRUMENTATION DIAGRAM COMPRESSOR 02250176 713 R03 S1 ...

Страница 32: ...1600C LP USER MANUAL SECTION 2 32 2 10 PIPING INSTRUMENTATION DIAGRAM ENGINE 02250176 713 R03 S2 ...

Страница 42: ...42 NOTES ...

Страница 46: ...1600C LP USER MANUAL SECTION 3 46 3 6 ID TANDEM AXLE 02250175 070 r00 ...

Страница 48: ...1600C LP USER MANUAL SECTION 3 48 3 8 ID 4 WHEEL 02250175 073 r00 ...

Страница 50: ...1600C LP USER MANUAL SECTION 3 50 3 9 ID WITHOUT RUNNING GEAR 02250175 075 r01 ...

Страница 52: ...NOTES 52 ...

Страница 56: ...NOTES 56 ...

Страница 68: ...68 NOTES ...

Страница 73: ...NOTES ...