1.1 g

enerAl

notes

on

sAfety

This operation manual is applicable for the machine LWG

12.

The machine may only be handled by personnel

who are qualified.

1.2 u

se

of

the

mAchine

for

PurPoses

for

which

it

is

intended

The machine ist intended for the cutting, roughing and

brushing of metal and stone materials.

1.3 i

ncorrect

use

All uses other than those described under section

1.2 are regarded as incorrect use and are there-

fore not admissible.

1.4 ec

declArAtion

of

conformity

Otto Suhner GmbH, Trottäcker 50, D-79701 Bad Säck-

ingen, hereby declares under sole responsibility that

the product with the serial or batch no. (see reverse

side) complies with the requirements under the Directive

2006/42/EG. Applied standards: EN ISO 12100, EN ISO

11148. Document Agent: M. Voyame. D-Bad Säckingen,

08/2017.

M. Voyame/Division manager

2. c

ommISSIonIng

2.1 P

rior

to

tAKing

the

mAchine

into

serVice

Fitting of hose coupling (inside diameter min. 7

mm, available as optional accessory, item no. 908

057, type DN 8). Use oiled compressed air (see

also air quality under section 2.3). Observe national regu-

lations.

2.2 t

AKing

the

mAchine

into

serVice

2.2.1

turn

on

/t

urn

off

1. n

oteS

on

S

afety

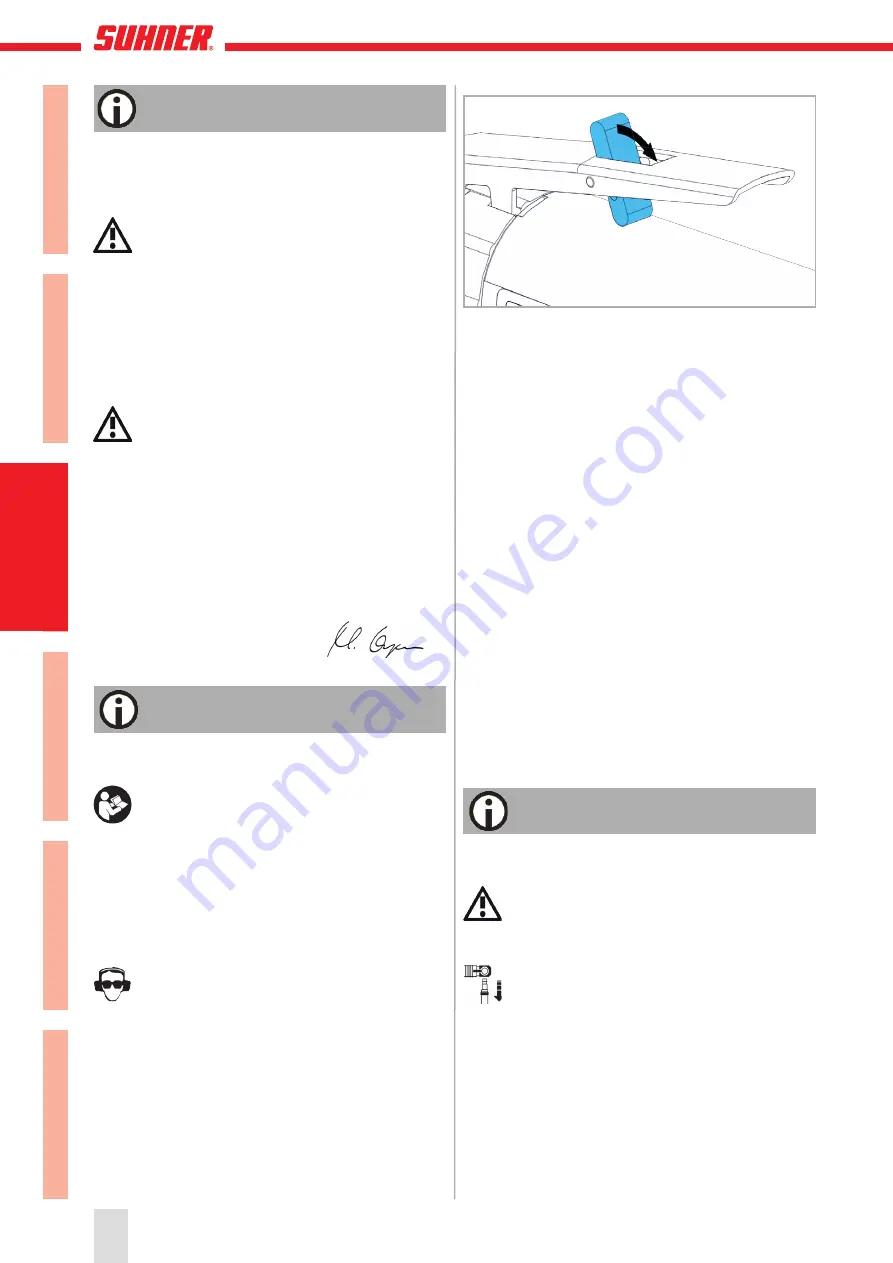

Tilt lock forward an press lever onplastic sleeve. Releas-

ing the lever switches the machine OFF.

2.3 r

Ating

dAtA

Pressure

max. 6.3bar

Power output

900W

Air consumption full load

1.1m

3

/min

Air consumption at idling

0.6m

3

/min

Setting oiler idle

2-3 drops/min

Wheel diameter

max. 125mm

Spindel thread

M14 / 5/8”

Length of spindle thread stud

20mm

No-load speed

12’000min

-1

Sound pressure level EN ISO 15744 81dB(A), K=3dB(A)

Sound power level EN ISO 15744

92dB(A), K=3dB(A)

Vibration EN ISO 28927-12

7.8m/s

2

, K=2.6m/s

2

Air quality DIN ISO 8573-1

3/4/4

Weight 1.700kg

2.4 o

PerAting

conditions

Temperature range during operation: 0 to +40°C

Relative air humidity: 95% at +10°C not condensed

3. h

andlIng

/o

peratIon

3.1 P

rotection

deVices

The machine may only be operated with the safety

guards and the additional handle fitted!

3.1.1 s

Afety

guArd

The safety guard was already correctly adjusted in

the factory. With this adjustment it can be brought

into the desired working position, or removed.

When the pressure point is overcome the protective guard

must rotate and snap in again without the use of exces-

sive force. Otherwise, either the protective guard has to

be readjusted or the locking mechanism has to be

cleaned.

16

P

ortugúes

Español

Italiano

English

F

rançais

Deutsch

English