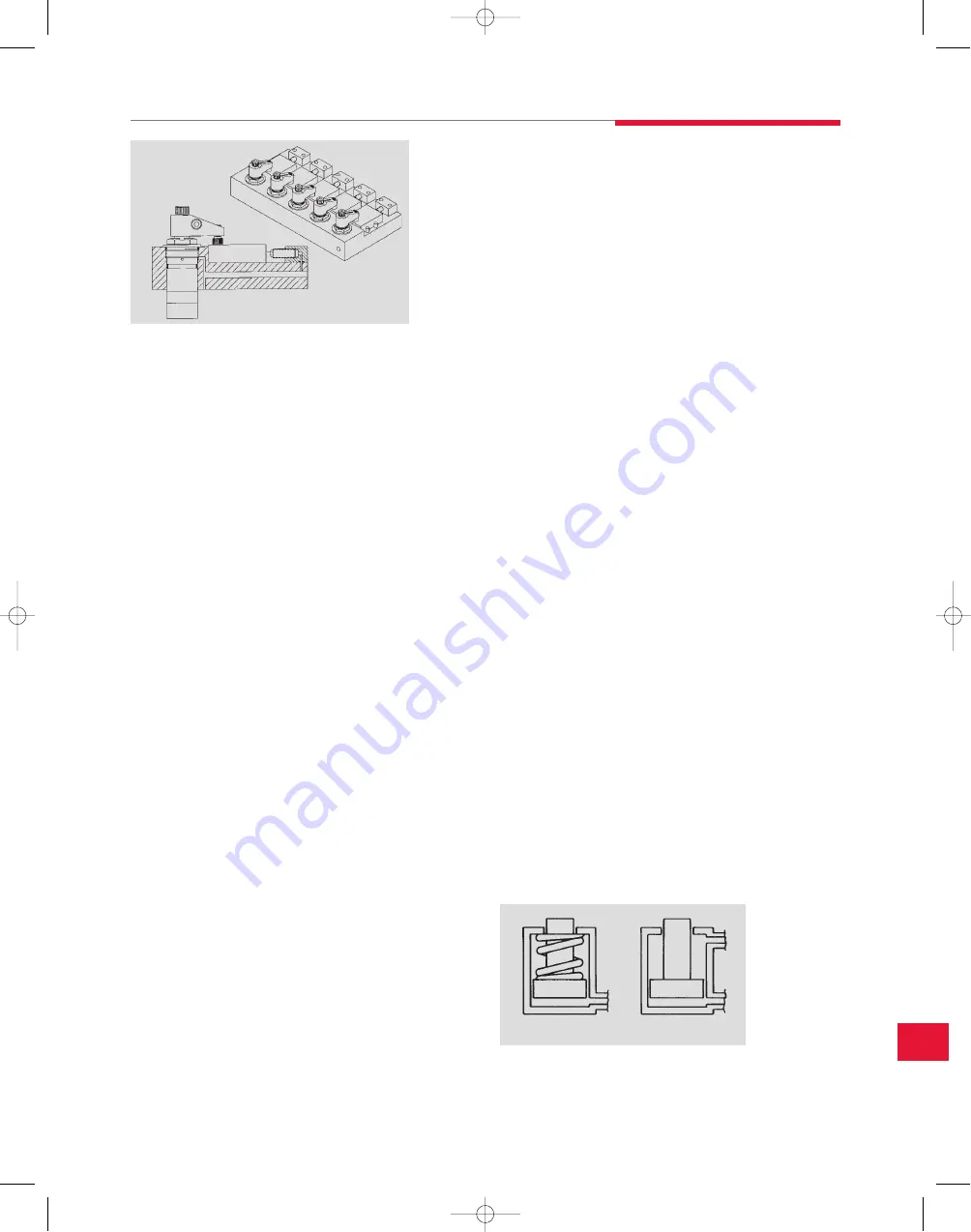

Manifold

Mounting

Manifold mounted components eliminate the need for external fittings,

tubing, and hoses because the fluid passages are machined directly

into the fixture. Securing the workholding component to the fixture

automatically makes the hydraulic connection.

Manifold Mounting:

Provides no-tool hydraulic connections

Saves valuable fixture space

Eliminates tubes, hoses or fittings that disrupt coolant

flow and collect chips

Simplifies post-machining fixture cleaning

Reduces assembly and maintenance time

Improves performance

Means fewer hydraulic connections resulting in fewer

potential leak points

Results in a cleaner, more professional-looking fixture

Plumbing Sizing

When designing and assembling your hydraulic system, keep in mind

that your choices of size and length of plumbing lines can significantly

change the performance of your fixture. The back-pressure created by

fittings, tubing and hoses can slow the operation of your system, especially

single-acting systems. Larger diameter plumbing runs with a minimum

number of bends and fittings will reduce this back pressure.

When sizing hydraulic lines, make sure you look at the inside diameter:

1⁄4" hose is not the same as 1⁄4" tubing. Hose is specified by its inside

diameter. Hydraulic tubing is usually specified by the outside diameter.

As example, 1⁄4" O.D., .035" wall tubing has an inside diameter of

.180", a flow carrying capacity of only 50% of that of the hose.

Single-acting clamps can develop only a limited amount of pressure to

force hydraulic fluid out of the clamp and allow it to retract. When the

return fluid from multiple clamps must share the same hydraulic line,

back pressure can easily become excessive and slow the

clamp’s retraction.

When connecting multiple clamps, you can use either a “daisy chain”

or “home run” configuration. In a daisy chain, you use a tee at each

clamp and run tubing from the first clamp to the second and then to the

third and then the fourth, etc. When using a home run configuration,

you begin at a manifold and run hydraulic lines all the way from the

manifold to each clamp.

The daisy chain method uses less tubing so it might appear that this

would minimize back pressure. However, in the daisy chain the fluid

from all of the clamps must pass through a single hydraulic line. In the

home run, while there may be longer runs, each line only has to

accommodate flow from one clamp.

The viscosity of the hydraulic fluid used will also affect back pressure.

Viscosity is affected by temperature. Contact the factory to discuss

applications running below room temperature. We recommend using

only DE-STA-CO fluids. Other fluids may have different viscosities or

other characteristics that can adversely affect system operation.

Single-acting vs. Double-acting

Another decision to be made early in the planning stage is whether to

use single-acting or double-acting components.

Single-acting components are typically actuated using hydraulic

pressure. When released, the pressure is removed and the actuator is

returned by a spring which forces the hydraulic fluid back into the

pump reservoir. This type of system is usually the most cost effective

because each actuator needs only one pressure source connection for

operation. Single-acting actuators should be vented to clean

atmosphere whenever appropriate. Remember to double the plumbing

for double-acting systems. This does, however, use more valuable

fixture space and adds to the cost.

Nevertheless, there are good reasons to use double-acting systems.

The larger and/or more complex the circuit design, the greater the

potential for return restrictions which will slow the return of the

single-acting actuators. Double-acting actuators are ideal for

applications which require both pushing and pulling or returning

clamps with heavy, custom designed attachments. They work well for

powering linkages which require fast actuation in both directions.

Double-acting clamps are often used in automated systems where

coordinating the action of the clamp with that of the rest of the system

requires fast, positive, predictable cycle times. By installing pressure

switches in both the pressure and return lines, the status of the clamp

can constantly be monitored.

DE-STA-CO

Subject to technical modifications without notice

15.9

S

tr

o

n

g

H

o

ld

C

la

m

p

in

g

S

y

s

te

m

T

M

System design information

Single-acting

Double-acting

15_StrongHold.qxp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.9