THESE ADJUSTMENTS should not be disturbed until it is necessary to replace the xenon

bulb. At that time, the procedure on obtaining a smooth, round black spot, or “hot spot,” may have to be

repeated. Replace the cover plate over the bulb positioning controls.

BECAUSE OF NORMAL BULB AGING, and manufacturing tolerances between individual

xenon bulbs, it may be necessary to operate lamps at slightly higher or lower current settings to maintain

uniform light output when two or more spotlights are used in one installation. This entails a slight current

output adjustment at the xenon power supplies. See the power supply manual.

TO EXTINGUISH the arc, place the LAMP switch on the instrument panel to “OFF.” The

lamphouse blowers will continue to operate until the xenon power supply is de-energized. Allow the blowers to

operate for ten minutes before turning off the power supply; a forced-air bulb cooling cycle is required by all

bulb manufacturers.

DAILY OPERATION in the “Manual” mode requires only that the xenon power supply be

energized, the MODE switch be left in the “MAN.” position, and the lamp switched ON and OFF by means of

the LAMP switch. No bulb alignment or “warm up” are necessary. Always allow for the ten minute bulb

cooling cycle.

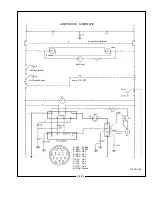

OPERATION IN THE “AUTO” MODE is intended for use only if the spotlight is to be used as

a fixed spot without an operator at the equipment. Place the MODE switch in the “AUTO” position, and the

LAMP switch to “ON.” The lamp will ignite when a sustained dry contact is made between the automation

leads 3 and 6, and extinguish when the contact is opened. See the INSTALLATION DIAGRAM in the power

supply manual. The lamphouse blowers will operate until the xenon power supply is de-energized; allow for ten

minutes bulb cooling.

BEFORE OPENING the lamphouse enclosure for servicing, allow the blowers to operate for

twenty minutes, or until the bulb has cooled to room temperature.

HANDLING THE SPOTLIGHT

GENERALLY THE BEST POSITION for the operator to stand is hear the center of the spot-

light on the right side. The angle of tilt, the size of the porthole, and the layout of the spotlight position may

dictate another location.

EACH OPERATOR will, after a few minutes of operation, generally develop his own system

and position for most convenient operation.

THE HORIZONTAL SWING and vertical tilt are individually adjustable to give the desired

degree of friction to suit the operator. The locking clamps are located on the right side of the yoke assembly.

THE EASE with which the spot size control handle (“trombone”) can be operated may be

adjusted by means of the nylon friction brake screw in the outrigger of the large lens carriage casting. To access

this adjustment, open the color boomerang and remove the gel frames. Slide the large lens carriage to the

extreme rear position. Reach through the boomerang housing and loosen the nylon friction screw locknut. Turn

the nylon friction screw clockwise to increase drag, or counterclockwise to relieve. Tighten the locknut after the

desired adjustment is reached.

XG2/011

Содержание XENON GLADIATOR II

Страница 2: ......

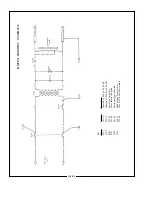

Страница 27: ...1 2 3 4 5 6 7 8 9 10 11 12 13 FIGURE 1 XG2 025 ...

Страница 29: ...1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 FIGURE 2 XG2 027 ...

Страница 32: ...1 2 3 4 5 6 7 8 9 10 11 12 13 FIGURE 3 XG2 030 ...

Страница 34: ...1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 FIGURE 4 XG2 032 ...

Страница 36: ...1 2 3 4 5 6 7 8 9 10 FIGURE 5 IGNITER ASSEMBLY XG2 034 ...

Страница 39: ...FIGURE 6 XG2 037 ...

Страница 41: ...FIGURE 7 XG2 039 ...

Страница 43: ...FIGURE 8 XG2 041 ...

Страница 46: ...58 59 FIGURE 9 Item 58 Bracket mounts to back surface of Item 31 XG2 044 ...

Страница 50: ...FIGURE 10 47 XG2 048 ...

Страница 53: ......

Страница 54: ......