Page 9

23/03/01

Cold water pressure test:

The assembled boiler is to be subjected to a cold

water pressure test of 1.5 times the operating pressure.

The maximum test pressure of the boiler is 5.2 bar.

In addition, at the time of testing for water pressure,

no pressure control fittings or safety fittings may be

assembled which cannot be separated from the water

area of the boiler.

Only fill, slowly from the bottom via the filling and

draining cock.

Ventilate during the filling procedure from time to

time, until the water emerges.

If a nipple connection is leaking then drain off the

water via the filling and draining cock. Separate by

driving flat wedges around the perimeter of the join

between sections. New nipples MUST be used for re-

assembly.

Assemble and repeat test.

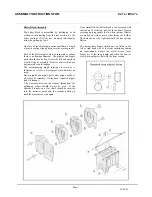

The order of assembly from (1) to (7) must be

observed.

Important points:

•

When fitting the long injection tube (1) (only

fitted to boilers with 7 sections or more) care

should be taken to ensure that the holes for the

direction of water, are facing upwards.

•

The boiler flow (3) must be assembled with the

connection facing upwards eccentrically.

•

The boiler return (2) must be assembled with the

connection facing downwards eccentrically.

•

It is possible to hinge the door to swing from

either side of the front section. Car should be

taken to ensure the burner plug is mounted

accordingly.

ASSEMBLY INSTRUCTIONS FOR: Ca 7s / BCa 7s

Содержание BCa7s

Страница 1: ...Page 1 23 03 01 Ca 7s and BCa 7s 61 235 kW INSTALLATION AND OPERATING INSTRUCTIONS ...

Страница 21: ......