Advantage 3000

USER MANUAL

R

EV

.

1.8

1) Introduction

2) Main Menu

3) Profile Settings

a)

Step, Target Temp, Ramp, Soak and Link settings

b)

Programmer, Slave and Unused selection

4) Operation Mode

a)

Operation RUN / STOP screen

b)

Output monitoring

c)

Function or program changing of “STOP” mode channels

d)

Trend all channels screen

e)

Detail channel screens

f)

Step function

g)

Manual Hold function

h)

Calibration screen

i)

PID settings

j)

Trend channel screen

5) Basic Settings

a)

Auto Hold Settings

b)

°C/F selection

c)

PID settings

d)

Copy data to USB

6) Extra settings

a)

Brightness setting

1) Introduction

2)

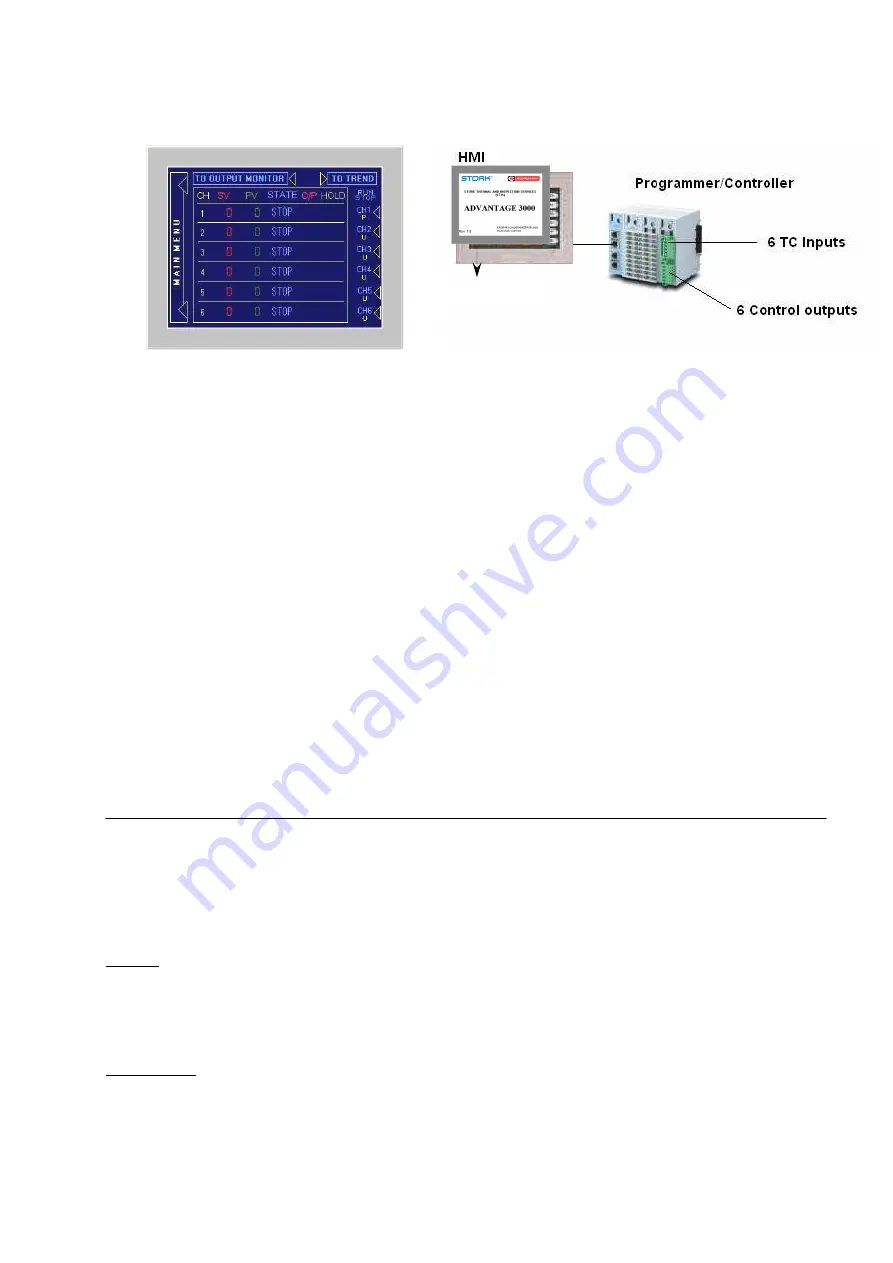

The Advantage 3000 is the latest innovation on Heat Treatment control technology which combines user friendly

operation with state of the art control and data logging as well. The heart of the Advantage 3000 is the Full color TFT

touch-screen from which you can set-up and run your system. The control is done by a dedicated rack-mounting system

that is located inside the cabinet.

Benefits:

User friendly operation

Cost and time saving installation

Better protection against dust and Heavy-duty environments

Build-in data logger

Copy .csv file to USB function

Basic features:

Colour TFT touch-screen

6 loop controller

Free selectable programmer/slave combinations

Up to 8 ramp/soaks per program

Auto and Manual Hold function

°C / °F selection on base unit

0 ~ 2400 °F only model available

Excel data sheet

Calibration function

Real time trend-charts (paperless recorder)

Output status monitor

Step function

Lock function against unauthorized operation

PID settings with Auto tuning