11

11.1 Hopper emptying

procedure

The hopper drain cap can be removed to help empty the hopper.

Any remaining product is best removed by using an industrial vacuum

before the feed block is removed from the machine. Once the feed

block has been removed from the machine dispose of any remaining

product held in the feed block. Release the bottom calibration door

and check the air chambers for any sign of debris or build up of

product and clear as necessary.

11.2 Clearing a feed hose

blockage

In the unlikely event of a blockage remove the hose and clear any obstruction and from within the hose or

manifold on the machine. Remove the feed block and check the air chamber below the feed block opening and

clear any debris. Re-position the feed hoses if this has been the cause of the problem (See page 12 for advice

on best hose positioning)

11.3 Checking the feed motor

If the control system has alarmed to indicate the feed motor has stalled

WARNING

this procedure must be carried out by a competent person who is aware of any

risks involved

Firstly empty the hopper then remove the feed block assembly

as described on page 10

Remove the motor guard by releasing the fixing screws

Check to see if the feed motor shaft rotates when pressing the

prime button. If the shaft is not rotating this may indicate the

motor had been damaged and needs to be replaced.

For any parts required or if no faults found and the alarm persists contact your local stocks dealer

Содержание Turbo Jet 10 i-CON

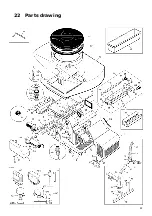

Страница 22: ...22 22 Parts drawing 5 ...

Страница 26: ...26 26 Feed roller kits ...

Страница 29: ...29 29 Notes page ...

Страница 30: ...30 ...