© 2007 Stevens AeroModel.

Page 32 of 33

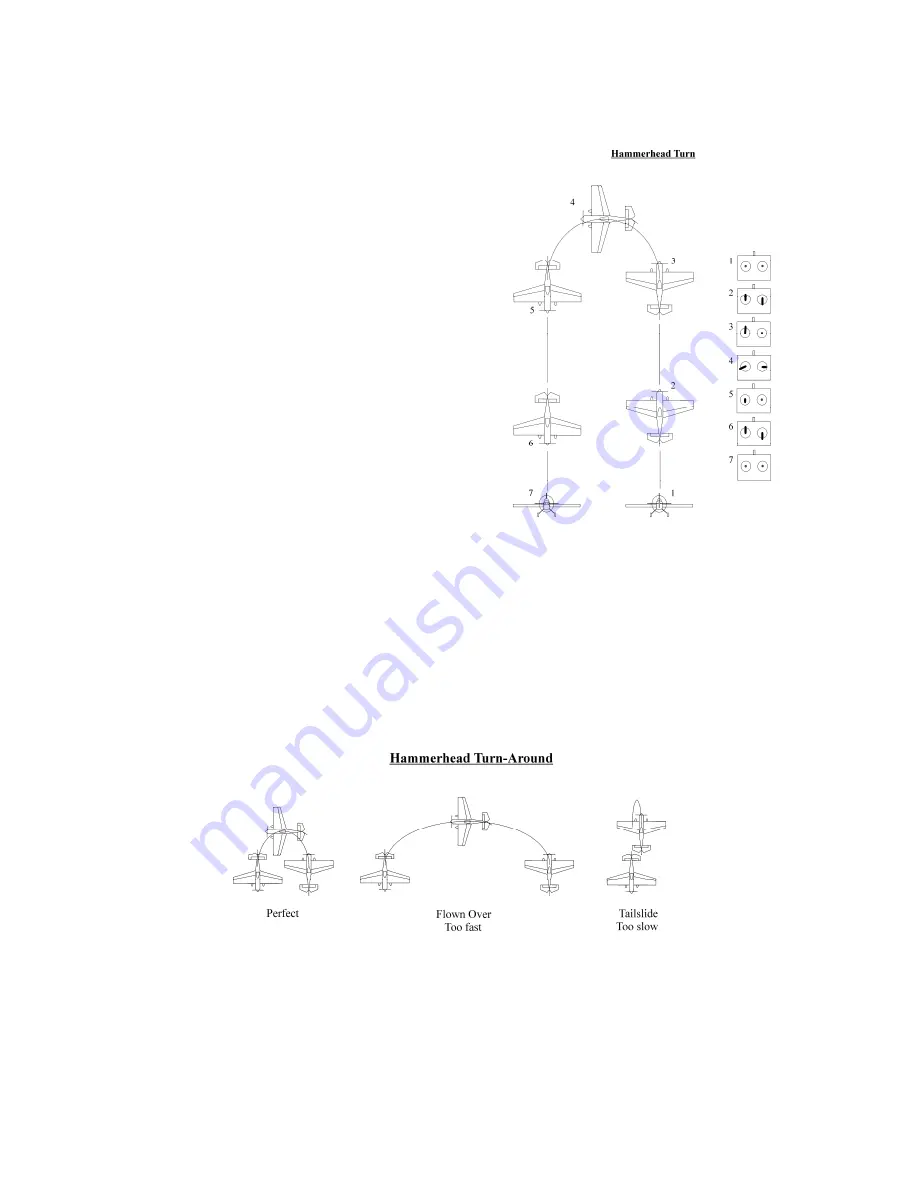

The Hammerhead Turn

Begin the hammer head turn from a level line with enough throttle to

draw a long vertical upline – but not so much that the model climbs

so high that it is hard to see. Execute a 1/4 loop up to a vertical line.

Establish and correct for a good vertical line. You will probably need

to add right rudder during the pull up to maintain good yaw balance

on the upline. As the model decelerates, add right aileron to counter

torque’s tendency to roll the model to the left. This will increase as

the model slows. Adjust the throttle to maintain a slow deceleration,

up to and including reducing the throttle enough to “stop” at the point

that you want. Do not close the throttle at the top of the maneuver,

as we need thrust over the rudder to intitiate the turn-around. A

good technique is to reduce the throttle to a point that allows a slow

deceleration and stop point, and maintain that throttle setting

through the entire turn-around.

At the precise moment that the model stops vertical motion, add full

left rudder, and increase the right aileron to maintain a true vertical

track (no wing torque) during the turn-around. The model should

pivot within one wingspan diameter, to a nose down position. During

your first few hammerhead turns, you will need to adjust the amount

of rudder, and aileron needed to rotate the model to the vertical

downline. For most of my models, I end up using full left rudder and

½ right aileron. If you use too little aileron, the model will torque at

the top of the hammerhead. Torquing is the tendency of the model,

at very slow airspeeds, to roll to the left in responseto the effects of

torque.

The point at which you add rudder for the turn-around portion of the maneuver is also something that will take time and

experience to perfect. Some models don’t have enough rudder authority to rotate the nose rapidly enough at zero forward

(vertical) motion, so the turn-around will have to occur earlier. The point at which you initiate the turn-around is often

referred to as the “kick point” (in full scale aerobatics the rudder is on the foot controls, thus the “kick” of rudder for the

turn-around).

If the “kick point” is early, the model will fly over the top of the hammer (rather than a tight pirouette), and the radius of the

turn-around will be too large. If the “kick point” is late, the model may actually descend backwards (tailslide). A perfect

“kick” will make the model rotate within one wingspan radius to a vertical nose-down position. Adjust the airspeed at the

“kick point” to perfect the turn-around.

Once the model transitions to the vertical down position, your work is not done. Make sure that you actually establish the

vertical downline. Depending upon the quality of the turn-around, you will have to correct in pitch, roll, and yaw to re-

establish the vertical. Finish the maneuver with a normal ¼ loop to a level line.

Here’s to blue skies, calm winds, round loops, and soft touchdowns

Good luck with your new model!!

www.rcpilotguide.com

Содержание SHAFT S400

Страница 4: ...2007 Stevens AeroModel Page 4 of 33 Laser Cut Parts Inventory...

Страница 5: ...2007 Stevens AeroModel Page 5 of 33 Laser Cut Parts Inventory...

Страница 25: ...2007 Stevens AeroModel Page 25 of 33 THIS PAGE HAS BEEN PROVIDED TO SCHEME A COLOR SCHEME...

Страница 26: ...2007 Stevens AeroModel Page 26 of 33...