T

herm

e

lecT

h

ydronic

S

afeTy

i

nformaTion

SAFETY PRECAUTIONS

1. Fully assemble the system and load ceramic heat storage brick prior to energizing the system.

2. Pressure relief valve must be installed prior to operation of the system.

3.

Use or storage of explosive or flammable gases or liquids within close proximity of the system presents

a hazard.

4.

Clearance requirements are critical to safe operation of the system. Follow all requirements specified

in this manual (page 3.03).

5. Keep the top of system clear.

6. Ensure openings for ventilation to the heat sink are clear and unobstructed.

7. Use caution when working around the heating system as inlet and outlet piping can be very hot.

8. De-energize all branch circuits before servicing. This heating system may be connected to more than

one branch circuit.

9.

Installation of and/or service to this heating system should be performed by a qualified technician

in accordance with information contained herein and with national, state, and local codes and

requirements.

10. Repeated error codes on the system display (pages A.10 – A.12) indicate a need for service by a

qualified technician.

11. Special requirements must be considered if placing the system in a garage or other area where

combustible vapors may be present. Consult local, state and national codes and regulations to ensure

proper installation.

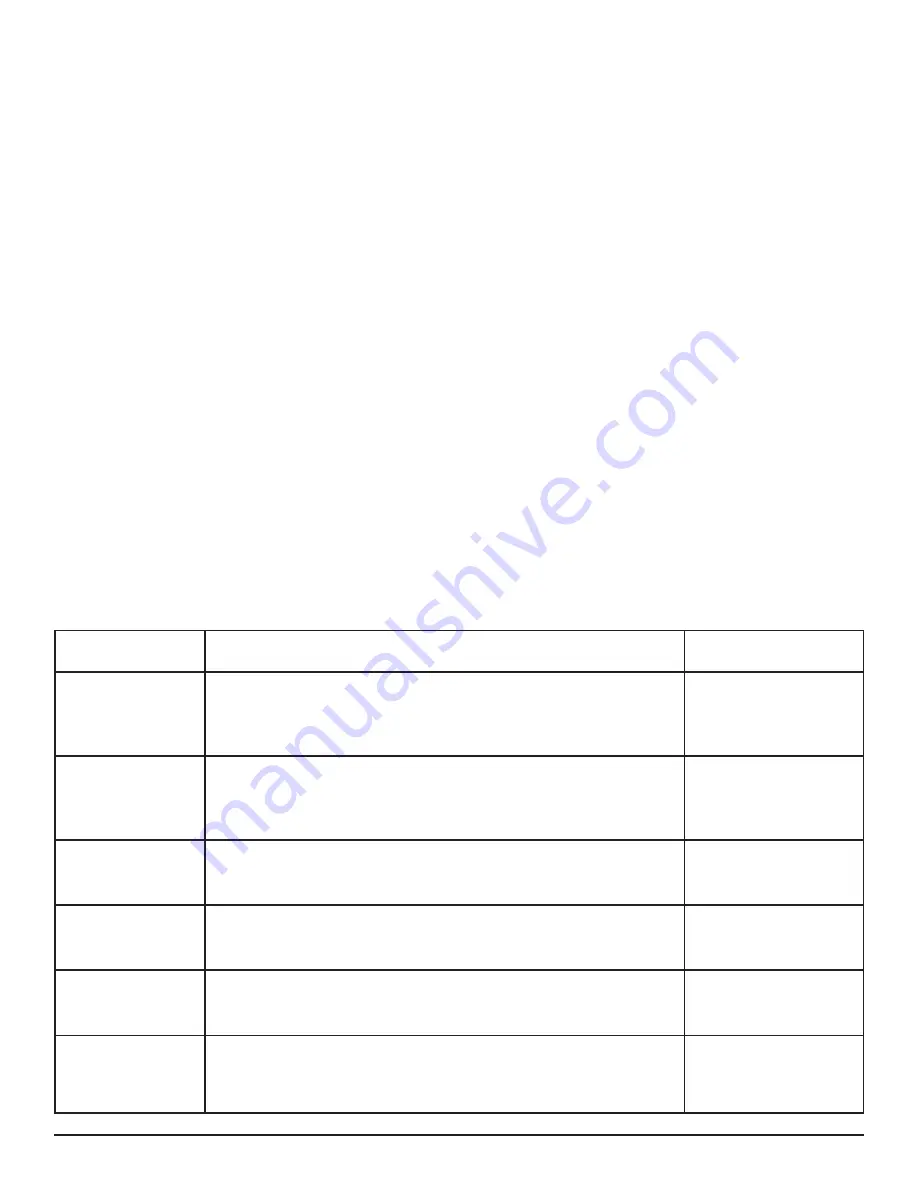

BUILT-IN SAFETY DEVICES

The ThermElect Hydronic heating system incorporates safety devices to ensure normal operating temperatures

are maintained. The chart below describes these safety devices.

DEVICE NAME

FUNCTION

LOCATION

ON SYSTEM

Core Charging

High Limit

Switches

(Auto Reset)

These limit switches monitor the core and top temperatures. If

normal operating temperatures are exceeded, the system will

display "CORE FAIL" and the elements will not be allowed to

operate.

Right side and top of

the system.

Heat Exchanger

Limit Switch

(Manual Reset)

This linear limit switch monitors the temperature of the water in

the exchanger and interrupts power to the core blower if a water

temperature of 250

o

F/121

o

C is exceeded. If this limit switch opens,

contact a qualified service technician.

Behind front lower

painted panel. Reset

button visible in lower

right front corner.

Outlet Water

Temperature Limit

Switch (Auto Reset)

This linear limit switch monitors the temperature of the water in

the exchanger and interrupts power to the core blower if a water

temperature of 225

o

F/107

o

C is exceeded.

Behind front lower

painted panel.

Pressure Relief

Valve

If the water pressure exceeds maximum psig, the pressure relief

valve opens. Once water pressure of less than maximum psig is

achieved, the valve closes.

Factory provided, field

installed to outlet of

heat exchanger.

Definite Purpose

Contractors

If one or more of the core charging high limits open, the definite

purpose contactors will interrupt power to the heating elements

until the core limit closes.

Inside the Electrical

Panel.

Heat Sink High

Limit Switches

(Auto Reset)

These limit switches monitor the heat sink temperature for

abnormal temperature rise. If the temperature of the heat sink is

too high, the limits open and remove power from the SSR’s causing

the elements to turn off.

Inside the Electrical

Panel.