gb

-

10

-

Tightening torque adjustment

In the tool's rear there is an LCD screen which signals

the tightening torque. Under the screen there are two

buttons, one to fasten the torque and the other one

to loosen it. You can set the automatic tightening stop

within 150Nm and 350Nm. If you keep pressing the

fastening button the screen will show a '888' message

meaning the tool will keep tightening as long as the

trigger is activated.

Loosening torque adjustment.

T

he tool does not have a loosening adjustment. The

tool will apply the maximum torque 500Nm spinning to

the left for a fast and efficient loosening.

Reversing the rotational direction

The rotational direction switch is used to reverse the

rotational direction of the machine. However, this is not

possible with the On/Off switch actuated.

–

Right rotation:

Press the rotational direction switch rightward to

the stop.

–

Left rotation:

Press the rotational direction switch leftward to the

stop.

Switching On and Off

– To start

the machine, press the On/Off switch and

keep it pressed.

– To switch off the machine, release the On/Off

switch.

To save energy, only switch the power tool on

when using it.

WORKING ADVICE

Before any work on the machine itself, pull the

mains plug.

Apply the power tool to the screw/nut only when

it is switched off.

Rotating tool inserts can slip off.

At temperatures below the freezing point, run the ma-

chine for approx. 3 minutes at no-load to improve its

lubricating capacity.

The torque depends on the impact duration. The maxi-

mum achieved torque results from the sum of all indivi-

dual torques achieved through impact. The maximum

torque is achieved after an impact duration of 3–5

seconds. After this duration, the tightening torque is

increased only minimally.

However, the transmission housing heats up

noticeably.

Note:

The consequences of excessive heating-up are

high wear of all hammer mechanism components and

a high requirement of lubricant.

The impact duration is to be determined for each

required tightening torque. The actually achieved

tightening torque is always to be checked with a torque

wrench.

Screw Applications with Hard, Spring-loaded or

Soft Seat

When in a test, the achieved torques in an impact

series are measured and transferred into a diagram,

resulting in the curve of a torque characteristic. The

height of the curve corresponds with the maximum

reachable torque, and the steepness indicates the

duration in which this is achieved.

A torque gradient depends on the following factors:

– Strength properties of the screws/nuts

– Type of backing (washer, disc spring, seal)

– Strength properties of the material being screwed/

bolted together

– Lubrication conditions at the screw/bolt connection

The following application cases result accordingly:

– A

hard seat

is given for metal-to-metal screw

applications with the use of washers. After a relatively

short impact duration, the maximum torque is reached

(steep characteristic curve). Unnecessary long impact

duration only causes damage to the machine.

– A

spring-loaded seat

is given for metal-to-metal

screw applications, however with the use of spring

washers, disc springs, studs or screws/nuts with coni-

cal seat as well as when using extensions.

– A

soft seat

is given for screw applications, e. g.,

metal on wood or when using lead washers or fibre

washers as backing.

For a spring-loaded seat as well as for a soft seat, the

maximum tightening torque is lower than for a hard

seat. Also, a clearly longer impact duration is required.

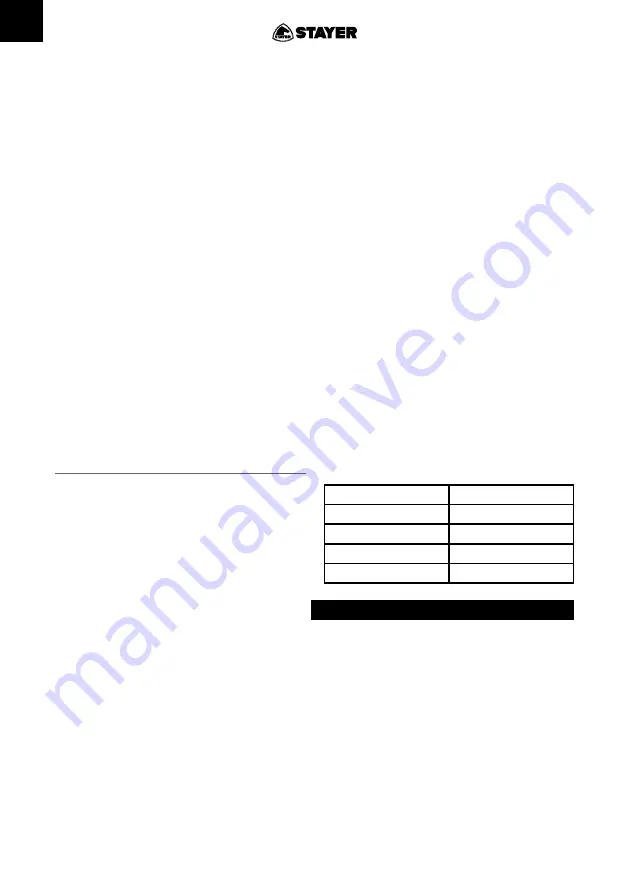

Reference Values for Maximum Screw/Bolt

Tightening Torques

Calculated from the tensional cross-section; utilization

of the yield point 90 % (with friction coefficient μtotal =

0.12). As a control measure, always check the tighte-

ning torque with a torque wrench.

Nut size

Nm

M10-M12

40-80

M12-M16

100-200

M14-M16

120-200

M18-M24

200-350

2_MAINTENANCE AND SERVICE

Maintenance and Cleaning

Before any work on the machine itself, pull the

mains plug.

For safe and proper working, always keep the ma-

chine and ventilation slots clean.

In extreme working conditions, conductive dust

can accumulate in the interior of the machine

when working with metal. The protective insula-

tion of the machine can be degraded. The use of

a stationary extraction system is recommended in

such cases as well as frequently blowing out the

ventilation slots and installing a residual current

device (RCD).

Содержание IW 500 D K

Страница 12: ...NOTES...

Страница 13: ...NOTES...