26

8. If the Flame Sensor does not detect a strong enough flame, the

Ignition Control shuts off the Gas Valve and allows the blower to

purge the unit for 30 seconds. At that time, the Ignition Control

restarts with step 6. It will try and ignite the main burners 2 more

times. If the unit does not light, the Ignition Control will wait 15

minutes and then restart at step 6. This cycle will continue until the

unit lights or the power is shutoff to the unit.

9. If the Flame Sensor detects a strong flame, the Ignition Control

will energize the main gas valve output, which will cause the

blower to run at a pre-determined high speed until call-for-heat

is removed.

10. Once the unit is satisfied, the Thermostat will shut off the blower,

Gas Valve and Ignition Control and the unit will be in standby

mode until another call for heat is initiated by the thermostat.

See the flow chart on page 27 for more detailed information.

seQuenCe of operation

The following information will describe the Sequence of Operation

for this water heater.

1. Switch power on to unit.

2. Thermostat calls for heat.

3. UGb send PWM signal to blower to start the blower at high pre-

purge speed.

4. The blower pressure switch is closed, 24VAC power is applied to

the Ignition Control Module.

5. 20 seconds later blower starts to slow down to a slow ignition

speed preparing for ignition process.

6. 30 seconds after being energized, the Ignition Control provides

power to the Spark Igniter and opens the Gas Valve.

7. Ignition Control maintains spark for up to 4 seconds and monitors

Flame Sensor to determine if burner is lit.

lighting & operating laBel

S

N

O

I

T

C

U

R

T

S

N

I

G

N

I

T

A

R

E

P

O

G

N

IT

A

R

E

P

O

E

R

O

F

E

B

D

A

E

R

Y

T

E

F

A

S

R

U

O

Y

R

O

F

1.

2.

STOP! Read the safety information

above on this label.

Set the ON/OFF switch on the control box to

the “OFF” position.

6. Turn on all electrical power to the appliance.

7. Set the ON/OFF switch on the control box to

the “ON” position.

8. Set the thermostat to the desired setting.

9. If the appliance will not operate, follow the

instructions “TO TURN OFF GAS TO

APPLIANCE” and call your technician or gas

supplier.

Wait five (5) minutes to clear out any gas.

If you then smell gas, STOP! Follow “B”

in the safety information above on this label. If

you don’t smell gas, go to the next step.

3. Set the thermostat to the lowest setting.

4. This appliance is equipped with a device which

automatically lights the burner.

DO NOT TRY TO LIGHT THE BUNER BY HAND.

5.

CAUTION: Hotter water increases the risk

of scald injury. Consult the instruction

manual before changing temperature.

WARNING: TURN OFF ALL ELECTRIC

POWER BEFORE SERVICING.

FLAMMABLE

WARNING:

If you do not follow these instructions exactly, a fire or

explosion may result causing property damage, personal injury

or loss of life.

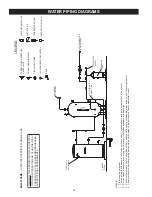

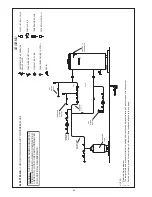

BEFORE OPERATING: ENTIRE SYSTEM MUST BE FILLED WITH WATER AND AIR PURGED FROM ALL LINES.

A.

B.

This appliance does not have a pilot. It is equipped with

an ignition device which automatically lights the burner.

Do not try to light the burner by hand.

C. Use only your hand to push the control buttons. Never use

tools. If the control buttons will not push in, don’t try to

repair them, call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately contact a qualified installer or service agency

to replace a flooded water heater. Do not attempt to repair

the unit. It must be replaced!

BEFORE OPERATING smell all aroung the area for gas.

Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Immediately call your gas supplier from a neighbor's

phone. Follow the gas suppliers instructions.

If you cannot reach your gas supplier, call the fire

department.

Do not touch any electric switch;

do not use any phone in your building.

2. Set the ON/OFF switch on the control box to

the “OFF” position.

1. Set the thermostat to the lowest setting.

3. Turn off all electrical power to the appliance

if service is to be performed.

TO TURN OFF GAS TO APPLIANCE

ON

OFF

figure 23.

Содержание SBL81120NE

Страница 49: ...49 Model Dimension A SBL 120 154 68 SBL 180 199 250 A 76...

Страница 50: ...50 Notes...