23

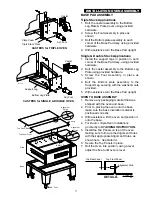

EIC

S1

24

17

THS 2

M.V. 3

SENSE 4

GND

5

51

35

S2

E1

E2

S1

S2

SCG

5

64

3

8

71

2

14

28

13

54

22

18

21

12

27

40

20

YEL

TA

CH SIGNAL

WHT

- REF

RED + REF

GR

Y

L2

BRN CAP

(CW)

BLK CAP

(CCW)

GM

C1

27

13

14

18

22

29

29

40

J7

6 = COM

5 = ENABLE

4 = DIR

3 = SPEED

2 = COM

1 =

TA

CH

1

PCB

CPI GEN-1

J2

T/C

TYPE K

J1 (IN)

1 = H

2 = N

J5 (OUT)

1 = N/C

2 = 24V

3 = COM

SH (BLK)

+ (YEL)

- (RED)

--

--

--

28

12

54

J6

6 = COM

5 = ENABLE

4 = DIR

3 = SPEED

2 = COM

1 =

TA

CH

1

1

1

33

25

--

34

23

CB1

BLK

1

CB2

WHT

11

39 30

38 53

51

25

31

5

33

32

VS

VC

DO

NOT

USE GRD

LUGS

34

23

26

37

26

24

37

35

S1

1

4

2

5

8

15

2

30

LT

2

1

2

3

NC

C

~

3

(-)

NO

TCD

6

~

2

(+)

52

3

52

56

NOTES:

1) F

A

NS MUST

ROT

A

TE IN DIRECTION SHOWN

AS VIEWED FROM REAR OF OVEN.

REMOVE "DIR" JUMPER OR SWITCH V & W CONNECTIONS ON INVER

T

ER.

2)

ADJUST

COOLDOWN

TIMER

T

O

55 MINUTES (APPROX.)

3) IGNITION/SP

A

RK WIRE (S2) SUPPLIED WITH BURNER (NOT

LABELED). BLACK, RED

OR ORANGE, RUBBER INSULA

TED, 1/4" FEMALE QC BOTH

TERMINAL

ENDS.

4) FLAME SENSE WIRE (S1) SUPPLIED WITH BURNER (NOT

LABELED). BLUE, WHITE

OR ORANGE, PLASTIC INSULA

TED, 1 EACH 1/4" & 3/16" FEMALE QC

TERMINAL

ENDS.

5)

TRANSFORMER IS MUL

T

I-VOL

TA

GE CAP

ABLE

AND HAS BARE WIRE LEADS.

A

T

TA

CH

TERMINALS ON

YELLOW

, BLUE & BLACK WIRES

AND NUMBER

AS SHOWN.

A

T

TA

CH

TERMINALS

T

O

THE ORANGE, RED & WHITE WIRES BUT

ONL

Y

NUMBER

THE

LEAD FOR

THE VOL

TAGE REQUIRED (208V=200-225V

, 240V=225-250V).

6) INVER

TER DEF

A

UL

T

SETTINGS:

TQ LIMIT

= 100%, BOOST

= 10-15%, DECEL

= 0-10%,

ACCEL

= 25-35%, MAX = 30% (SET

FOR 60HZ OUTPUT)

56

55

4

55

TB

36 48

50 4

39

47

49

-

-

-

TB

21 8

9 7

15

20

19

-

-

-

TB

11

SSC

XF1

0V

120V

208V

240V

ORN

RED

WHT

BLK

LT1

SD1

SD2

C

NO

C

NO

10

10

17

6

5

6

BLU

YEL

F4

F3

SCF

POWER

FAULT

TQ LIMIT

BOOST

MAX

ACCEL

TQ

DECEL

L1

L2

W

V

U

E2 E1 S1 S2 S3 DIR

58

59

36

38

NC

C

~

2

(-)

NO

TFS

~

1

(+)

61

62

61

62

45

41

44

42

46

43

44

45

46

57

43

41

42

60

60

F1

F2

F5

BLU

BRN

48

47

9

53

C

NO

NC

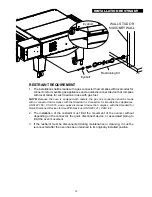

SD2

: "HIGH" PRESSURE POR

T

A

T

TA

CH

T

O

COMBUSTION BLOWER

SD1

: "LOW" DRAFT/V

ACUUM POR

T

A

T

TA

CH T

O

DRAFT

TUBE

LT

1

LT

2

CB

E1

E2

6.0

T/C

2M-Z9031 revG

XF2

2

1

5

8

7

11

6

12

31

J1

J1

19

32

7

L1

L2

CB2

CB1

CE SPECIFIC WIRING:

1) SUPPLEMENT

A

L WIRING KIT

REQUIRED

2)

TRANSFORMER & POWER INLET

CONNECTIONS

ARE DIFFERENT

FROM UL

WIRING

C1

CAP

A

CIT

O

R, GEARMOT

O

R RUN

CB1 CIRCUIT

BREAKER

CB2 CIRCUIT

BREAKER

E1 ELECTRODE,

SP

ARK

E2 ELECTRODE,

SENSE

EIC

ELECTRONIC IGNITION CONTROL

F1

F

A

N,

AIR CIRCULA

TION (W/

TEMP

SWITCHES)

F2

F

A

N,

AIR CIRCULA

TION (W/

TEMP

SWITCHES)

F3

F

A

N, CONTROL

BOX MUFFIN

F4

F

A

N, CONTROL

BOX MUFFIN

F5 F

A

N,

COMBUSTION

AIR

GM GEARMOT

O

R

LT

1

LIMIT

, TEMP

(COOK CHAMBER, BULB & CAP)

LT

2

LIMIT

, TEMP

(CONTROL

BOX, MAN. RESET)

PCB

PROGRAMMABLE CONTROL

BOARD

SCF

SPEED CONTROL, F

A

N (INVER

TER)

SCG

SPEED CONTROL, GEARMOT

O

R (OCT

AL

BASE)

TCD TIMER,

COOLDOWN

TFS TIMER,

F

A

N

ST

AR

T

SD1

SWITCH, DIFFERENTIAL

PRESSURE

SD2

SWITCH, DIFFERENTIAL

PRESSURE

S1

SWITCH, MAIN (DPST)

SSC SWITCH,

ST

ANDBY

COOLDOWN

XF1

TRANSFORMER, 24V UL

XF2

TRANSFORMER, 24V CE

VS

V

A

LVE, SINGLE (ON/OFF HIGH FIRE)

VC

V

A

LVE, COMBINA

T

ION (REGULA

T

O

R/LOW FIRE)

T/C THERMOCOUPLE

(TYPE

K)

MOV

MET

AL

OXIDE V

A

RIST

OR

TB TERMINAL

BLOCK(S)

WIRING DIAGRAM PROVIDED ON THE INSIDE COVER OF

YOUR CONTROL

BOX T

O

P

LID.

Содержание Ultra-max UM3240

Страница 27: ......