10

VENTILATION

A VENT IS REQUIRED: Local codes prevail. These are the "authority having

jurisdiction" as stated by the National Fire Protection Association, Inc. in NFPA

96-Latest Edition. For further ventilation information see below.

A ventilation hood is required to remove heat and cooking odors. For gas ovens, a ventilation

hood is also required to remove the products of combustion. The hood and HVAC installation

must meet local codes to gain approval by the authority having jurisdiction. Requirements may

vary depending on the location by city, county, and state. Obtain information from the authority

having jurisdiction to determine the requirements for your installation. Obtain information and

review copies of codes or documents that will be used to inspect and approve your installation.

Your ventilation hood supplier and HVAC contractor should be contacted to provide guidance. A

properly engineered and installed ventilation hood and HVAC system will expedite approval and

reduce oven maintenance costs. Proper ventilation is the responsibility of the oven's owner.

The ventilation hood must operate in harmony with the building HVAC system. (The ef

fi

ciency

of various hood designs makes it necessary to specify such a wide range of ventilator CFM.)

Make-up air must be supplied by either a hood design or the HVAC system to avoid a negative

pressure condition. This will vary with hoods from various manufacturers. Air supplied directly

from outside the building to the kitchen or oven area, non-tempered, could be used as supply

air but the design would have to accommodate potential operational changes.

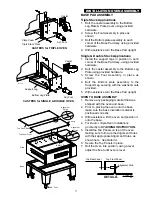

IL1177

RIGHT SIDE

FRONT SIDE

VENTILATION

CAPTURE AREA

VENTILATION

CAPTURE AREA

CAUTION

Prevent air

fl

ow through the cooking

tunnel. Air must NOT be directed onto

the oven's front or rear or to the sides

of the cooking area.

The following drawing shows a typical

installation and is intended to be a guideline.

This is not a rigid specification. Hood

dimensions and positioning over the oven

will vary with hood manufacturer & local

guidelines.

Damage sustained as a direct result of

improper ventilation will not be covered by

the warranty.

Failure to properly vent the oven can be hazardous to the health of the operator

and may result in operational problems, unsatisfactory baking, and possible

damage to the equipment.

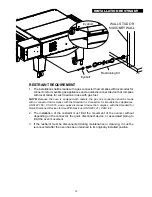

SMOKE CANDLE TEST

In order to verify the proper function of your ventilation system, a smoke candle test should

be done. If testing a multiple oven system, this test should be done on the bottom oven. The

conveyor coupling should be disconnected so conveyor does not move and the oven temperature

must be set and operating at a minimum of 480°F (249°C).

Test Procedure:

CAUTION

1. Wear heat-resistant gloves to prevent burns.

2. Put the smoke candle in an cake pan.

3. Insert candle through conveyor tunnel or oven

door.

(Use Star Smoke Candle

2W-Z5668.)

4. Light the fuse of the smoke candle and

immediately center the pan in the oven cavity on

the conveyor belt (keeping the oven door and

window closed).

5. Observe the smoke pattern coming out of

all oven openings and the collection of this

smoke by the ventilation system.

6. All smoke from the oven must be captured

by the ventilation system.

INSTALLATION VENTILATION

Содержание Ultra-max UM3240

Страница 27: ......