4

POWER SUPPLY

Models 530TD and 530TED are wired at the factory for operation on a single phase power supply.

For specific wiring, check the wiring diagram.

OPERATING INSTRUCTIONS

PLACE THE LAMINATED WARNING SIGN SUPPLIED WITH THE FRYER IN AN

AREA VISIBLE TO THE FRYER OPERATOR.

CLEAN KETTLE BEFORE USING

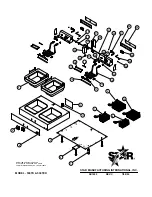

Take out baskets, push and hold element catch, lift up on element lift handle until elements lock

in a vertical position, and remove kettle. The kettle can be cleaned in a sink like any other pot or

container.

ADDING FAT

Replace kettle and swing the element down, making fryer ready for use. Add fat. Each kettle

has a 5 lb. fat capacity. A fat level line on the rear of the kettle will guide you in determining the

minimum cold fat level. A higher fat level can be used when frying bulky foods, such as chicken

or fish cakes. The fat level should be chosen carefully so that the foaming action of the fat does

not spill out of the kettle. If solid shortening is used, pack carefully around the elements.

CONTROLS

1. ON/OFF TWO-POLE SWITCH - Located on the front panel is a two-pole switch which turns

power on or off. An indicator light (Power On) is located on the control housing.

2. THERMOSTAT CONTROL - Located on the Control Housing, this control allows you to select

the desired frying temperature. A signal light "Heating" indicates when the element is on. When

the light goes off, the desired temperature has been reached.

3. HI-LIMIT THERMOSTAT - Should fat temperatures reach 450° F (230° C), this control will

shut off the power to the heating elements. The unit will still have power. The fat temperature

must cool to 400° F (202.4° C) and the manual reset button located on the back panel of the

control housing must be pressed to restore operation. Should the hi-limit control activate

twice in succession, the primary thermostat should be checked for malfunction by a qualified

service technician. Each pot is equipped with its own HI-LIMIT THERMOSTAT.

FRYING

After fat has been added, turn the switch on and set the thermostat at 200° F (92.4° C). After

the fat has melted, turn the thermostat to the desired setting. Included in this instruction booklet

is a frying chart and some helpful hints on fat use. After the selected fat temperature has been

reached, slowly lower half filled baskets into the fat. Do not overload baskets as this causes

foods to be improperly fried.

NOTE: Baskets should be allowed to drain after frying cycle. The kettle handles serve

as basket hangers.

IDLING

During idle periods turn thermostat control to approximately 200° F (92.4° C). The fast recovery

fryers can be brought up to frying temperature in a matter of minutes. Lowering the temperature

during idle periods saves energy costs and prolongs fat life.

DRAINING KETTLE

Turn switch to "OFF". Raise element to the first stop and allow to drain. Raise the element to the

vertical position and siphon the oil out of the kettle.

DO NOT ATTEMPT TO REMOVE THE KETTLE FILLED WITH HOT OIL. CONTACTING

HOT OIL CAN RESULT IN SEVERE INJURIES OR DEATH.

If you do not have a siphon, order one from your dealer or dip the oil out and strain into a

container. After oil has been removed, remove the kettle and clean.

CLEANING THE EXTERIOR

The exterior surfaces can be cleaned by regularly wiping with a soft cloth.

Any discoloration can be removed with a non-abrasive cleaner.

CAUTION

CAUTION

CAUTION