12

13

USING THE AIR COMPRESSOR

Your compressor does not require running in. Before use

ensure you have read and understood these instructions.

Before use ensure this compressor is fully assembled as per

pages 10 and 11.

Before starting run through this simple list;

1. Fully assembled.

2. Drain tap – open and drain tank.

3. Drain tap – close fully.

4. Check power lead for any damage. If damaged have

replaced by an authorised service centre.

5. Plug compressor into a standard 240V 10Amp AC

power point and turn ON.

6. Lift the red button to turn ON, see page 11, Pic. 5.

7. Allow the compressor to fill the air tank.

8. Turn the compressor OFF.

9. Turn the power point OFF and disconnect the

power lead from the power point.

10. Connect your air hose and air tools.

11. Reconnect to the power lead to the power point

and turn ON.

12. Turn your compressor ON.

13. Once turned on and you begin using the connected

air tools the compressor will start and stop without

warning. This is controlled by the pressure switch.

These pressure settings are factory set and should

not be changed.

IMPORTANT

Pumping starts at (minimum) 115PSI and stops at

(maximum) 145PSI. Once the initial pump up stage

has finished you can use the compressor.

This compressor has a maximum pressure of 10 bar.

Always regulate the outlet air pressure to match your

air tool.

Different air tools require different operating

pressures. Always check with the air tool

manufacturer if unsure.

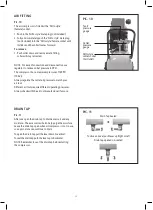

PIC. 6

Regulator

Air outlet

Water filter

bowl

Pull down to

drain/empty

FILTER REGULATOR

Pic. 6

This air compressor comes with a filter regulator, which will

filter some water and other particulates from the air as it

passes through the regulator.

To drain any fluid from the filer regulator;

1. Gently pull the nipple down.

2. Allow fluid to drain.

3. Allow nipple to seal.

To clean bowl (no tools required);

1. Unscrew the clear bowl.

2. Rinse the bowl in clear water.

3. Allow to air dry fully.

4. Screw the clear bowl back into place.