ENGLISH •

5

The pressure vessel quality certificate must be presented to

authorities, in case of inspection. Keep it in a safe place along

with the instruction manual.

COMPRESSOR INSPECTION

Inspect for signs of obvious or concealed freight damage.

Report any damage to the delivering freight carrier

immediately. Be sure that all damaged parts are replaced and

any mechanical problems are corrected prior to the operation

of the air compressor. The air compressor serial number is

located on the pump or tank. Please write the serial number in

the space provided in the service section for future reference.

Warning!

When using electric product, basic

safety precautions should always be followed to

reduce risk of fire, electric shock, and personal

injury.

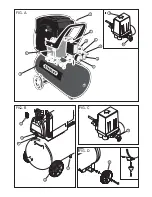

FEATURES (Fig. A and B)

1.

Air intake filter housing

2.

Compressor pump

3.

Pressure vessel

4.

Compressed air outlet (quick coupler), air not regulated

5.

Compressed air outlet (quick coupler), air regulated

6.

Outlet pressure gauge

7.

Tank pressure gauge

8.

Pressure regulator

9.

On/Off switch

10.

Safety valve

11.

Condensate drain cock

12.

Oil drain plug

13.

Oil sight glass

14.

Dip stick

15.

Wheels

TECHNICAL SPECIFICATIONS

NOTE:

The tank’s filling up time varies from ± 10%, according

to the installation.

1. Compressor (pump) Unit.-

Pull in and compresses

the atmospheric air.

2. Air Tank.-

Stores the compressed air.

3. Electric Motor.-

Makes the compressor unit run.

4. Pressure Switch.-

Controls the operation of compressor

to avoid that the maximum working pressure is surpassed.

See

Installation and Electrical Connection Chapter.

5. Safety Valve.-

Automatically exhausts the tank in case

the pressure is above the maximum allowed.

6. Check Valve.-

Keeps the compressed air inside the tank

avoiding its return when the compressor unit stops.

7. Drain.-

Removes the condensed water that accumulates

inside the tank.

8. Pressure Gauge.-

Shows the pressure inside the tank

in psi or bar.

9. Pressure Regulator with Valve.-

Used to adjust working

pressure on the indicator panel.

10. Protecting Screen.-

Protects the rotating parts.

11. Intercooler.-

Carries and cools down the compressed air.

12. Air Filter.-

Filters atmospheric air impurities that are

sucked by the compressor.

13. Valve.-

Controls the compressed air release, connects

KEY PARTS AND FUNCTIONS

CT224

CT250

Peso:

52,8 lbs 24 Kg

70,4 lbs 32 Kg

Altura:

24,0 in

625 mm

28,7 in

775 mm

Largo:

23,0 in

575 mm

27,1 in

325 mm

Ancho:

12,2 in

270 mm

12,2 in

730 mm

MODELO

CT224 CT250

DESPLAZAMIENTO

PRESIÓN MÁXIMA

l/min

50 Hz

140 140

60 Hz

185 185

ROTACIÓN

RESERVATÓRIO

(TANQUE) DE AIRE

psi

120 120

bar

8,4 8,4

rpm

50 Hz

2850

2850

60 Hz

3480

3480

Volumen geom. (L)

24 50

Tiempo

de llenar

MOTOR ELÉCTRICO

MONOFÁSICO

CON PROTECTOR

TÉRMICO

Tensión (V)

120/127 ó 220 120/127 ó 220

HP

1,5 1,5

Máx. HP

2,0 2,0

kW

1,1 1,1

Máx. kW

1,5 1,5

ACEITE

LUBRICANTE

PESO

PINTURA

NARANJA NARANJA

Kg

24 32

Lbs

52,8 70,4

Volumen (ml)

220 220

50 Hz

1’57

3’55

60 Hz

1’38

3’25

CT224

CT250

Peso:

52,8 lbs 24 Kg

70,4 lbs 32 Kg

Altura:

24,0 in

625 mm

28,7 in

775 mm

Comp.:

23,0 in

575 mm

27,1 in

325 mm

Largura:

12,2 in

270 mm

12,2 in

730 mm

MODELO

CT224 CT250

DESLOCAMENTO

TEÓRICO

PRESSÃO MÁXIMA

l/min

50 Hz

140 140

60 Hz

185 185

ROTAÇÃO

RESERVATÓRIO

Lbf/pol

2

120 120

bar

8,4 8,4

rpm

50 Hz

2850

2850

60 Hz

3480

3480

Volumen geom. (L)

24 50

Tempo

enchimento

MOTOR ELÉTRICO

MONOFÁSICO

COM PROTETOR

TÉRMICO

Tensão (V)

120/127 ou 220 120/127 ou 220

HP

1,5 1,5

Max. HP

2,0 2,0

kW

1,1 1,1

Max. kW

1,5 1,5

ÓLEO

LUBRIFICANTE

PESO

PINTURA

LARANJA LARANJA

Kg

24 32

Lbs

52,8 70,4

Volume (ml)

220 220

50 Hz

1’57

3’55

60 Hz

1’38

3’25

CT224

CT250

Weight:

52,8 lbs 24 Kg

70,4 lbs 32 Kg

Height:

24,0 in

625 mm

28,7 in

775 mm

Length:

23,0 in

575 mm

27,1 in

325 mm

Width:

12,2 in

270 mm

12,2 in

730 mm

MODEL

CT

S

224 CT250

DISPLACEMENT

MAX. PRESSURE

l/min

50 Hz

140 140

60 Hz

185 185

ROTATION

AIR TANK

psi

120 120

bar

8,4 8,4

rpm

50 Hz

2850

2850

60 Hz

3480

3480

Geom. Volume (L)

24 50

Filin

up time

ELETRIC MOTOR

SINGLE-PHASE

WITH THERMAL

PROTECTOR

Voltage (V)

120/127 or 220 120/127 or 220

HP

1,5 1,5

Max. HP

2,0 2,0

kW

1,1 1,1

Max. kW

1,5 1,5

OIL

CAPACITY

WEIGHT

COLOR REF:

ORANGE ORANGE

Kg

24 32

Lbs

52,8 70,4

Volume (ml)

220 220

50 Hz

1’57

3’55

60 Hz

1’38

3’25

CT224

CT250

Peso:

52,8 lbs 24 Kg

70,4 lbs 32 Kg

Altura:

24,0 in 625 mm

28,7 in 775 mm

Largo:

23,0 in 575 mm

27,1 in 325 mm

Ancho:

12,2 in 270 mm

12,2 in 730 mm

MODELO

CT224 CT250

DESPLAZAMIENTO

PRESIÓN MÁXIMA

l/min

50 Hz

140 140

60 Hz

185 185

ROTACIÓN

RESERVATÓRIO

(TANQUE) DE AIRE

psi

120 120

bar

8,4 8,4

rpm

50 Hz

2850

2850

60 Hz

3480

3480

Volumen geom. (L)

24 50

Tiempo

de llenar

MOTOR ELÉCTRICO

MONOFÁSICO

CON PROTECTOR

TÉRMICO

Tensión (V)

120/127 ó 220 120/127 ó 220

HP

1,5 1,5

Máx. HP

2,0 2,0

kW

1,1 1,1

Máx. kW

1,5 1,5

ACEITE

LUBRICANTE

PESO

PINTURA

NARANJA NARANJA

Kg

24 32

Lbs

52,8 70,4

Volumen (ml)

220 220

50 Hz

1’57

3’55

60 Hz

1’38

3’25

CT224

CT250

Peso:

52,8 lbs 24 Kg

70,4 lbs 32 Kg

Altura:

24,0 in 625 mm

28,7 in 775 mm

Comp.:

23,0 in 575 mm

27,1 in 325 mm

Largura: 12,2 in 270 mm

12,2 in 730 mm

MODELO

CT224 CT250

DESLOCAMENTO

TEÓRICO

PRESSÃO MÁXIMA

l/min

50 Hz

140 140

60 Hz

185 185

ROTAÇÃO

RESERVATÓRIO

Lbf/pol

2

120 120

bar

8,4 8,4

rpm

50 Hz

2850

2850

60 Hz

3480

3480

Volumen geom. (L)

24 50

Tempo

enchimento

MOTOR ELÉTRICO

MONOFÁSICO

COM PROTETOR

TÉRMICO

Tensão (V)

120/127 ou 220 120/127 ou 220

HP

1,5 1,5

Max. HP

2,0 2,0

kW

1,1 1,1

Max. kW

1,5 1,5

ÓLEO

LUBRIFICANTE

PESO

PINTURA

LARANJA LARANJA

Kg

24 32

Lbs

52,8 70,4

Volume (ml)

220 220

50 Hz

1’57

3’55

60 Hz

1’38

3’25

CT224

CT250

Weight: 52,8 lbs 24 Kg

70,4 lbs 32 Kg

Height:

24,0 in 625 mm

28,7 in 775 mm

Length: 23,0 in 575 mm

27,1 in 325 mm

Width:

12,2 in 270 mm

12,2 in 730 mm

MODEL

CT

S

224 CT250

DISPLACEMENT

MAX. PRESSURE

l/min

50 Hz

140 140

60 Hz

185 185

ROTATION

AIR TANK

psi

120 120

bar

8,4 8,4

rpm

50 Hz

2850

2850

60 Hz

3480

3480

Geom. Volume (L)

24 50

Filin

up time

ELETRIC MOTOR

SINGLE-PHASE

WITH THERMAL

PROTECTOR

Voltage (V)

120/127 or 220 120/127 or 220

HP

1,5 1,5

Max. HP

2,0 2,0

kW

1,1 1,1

Max. kW

1,5 1,5

OIL

CAPACITY

WEIGHT

COLOR REF:

ORANGE ORANGE

Kg

24 32

Lbs

52,8 70,4

Volume (ml)

220 220

50 Hz

1’57

3’55

60 Hz

1’38

3’25

STCT224

STCT250

Weight: 52,8 lbs 24 Kg

70,4 lbs 32 Kg

Height:

24,0 in 625 mm

28,7 in 775 mm

Length: 23,0 in 575 mm

27,1 in 325 mm

Width:

12,2 in 270 mm

12,2 in 730 mm

MODEL

ST

CT224

STCT250

DISPLACEMENT

MAX. PRESSURE

l/min

50 Hz

140

140

60 Hz

185

185

ROTATION

AIR TANK

psi

115 115

bar

8

8

rpm

50 Hz

2850

2850

60 Hz

3450

3450

Geom. Volume (L)

24 50

Filin

up time

ELETRIC MOTOR

SINGLE-PHASE

WITH THERMAL

PROTECTOR

Voltage (V)

120/127 or 2

3

0 120/127 or 2

3

0

HP

1,5 1,5

Max. HP

2,0 2,0

kW

1,1 1,1

Max. kW

1,5 1,5

OIL

CAPACITY

WEIGHT

COLOR REF:

ORANGE ORANGE

Kg

24 32

Lbs

52,8 70,4

Volume (ml)

300 300

50 Hz

1’57

3’55

60 Hz

1’38

3’25

CT224

CT250

MODEL

CT

S

DISPLACEMENT

MAX. PRESSURE

l/min

50 Hz

140

140

ROTATION

AIR TANK

psi

120 120

bar

8,4 8,4

rpm

50 Hz

2850

2850

60 Hz

3480

3480

Geom. Volume (L)

24 50

Filin

up time

ELETRIC MOTOR

SINGLE-PHASE

WITH THERMAL

PROTECTOR

Voltage (V)

120/127 or 220 120/127 or 220

HP

1,5 1,5

Max. HP

2,0 2,0

kW

1,1 1,1

Max. kW

1,5 1,5

OIL

CAPACITY

WEIGHT

COLOR REF:

ORANGE ORANGE

Kg

24 32

Lbs

52,8 70,4

Volume (ml)

220 220

50 Hz

1’57

3’55

60 Hz

1’38

3’25

STCT224

STCT250

Weight:

Height:

Length:

Width:

MODEL

STCT224

STCT250

DISPLACEMENT

MAX. PRESSURE

l/min

50 Hz

140

140

ROTATION

AIR TANK

bar

8

8

rpm

50 Hz

2850

2850

Geom. Volume (L)

24 50

Filin

up time

ELETRIC MOTOR

SINGLE-PHASE

WITH THERMAL

PROTECTOR

230

230

HP

1,5 1,5

Max. HP

2,0 2,0

kW

1,1 1,1

Max. kW

Voltage (V)

1,5 1,5

OIL

CAPACITY

WEIGHT

COLOR REF:

ORANGE ORANGE

Kg

24 32

Volume (ml)

300 300

50 Hz

1’57

3’55

24 Kg

625 mm

575 mm

270 mm

32 Kg

775 mm

325 mm

730 mm

YELLOW

YELLOW