9

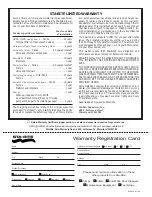

PUMP SERVICE

Pump should only be serviced by qualified personnel.

Be sure to prime pump (Pg. 7) before starting.

Before removing trap cover:

1. STOP PUMP before proceeding.

2. CLOSE GATE VALVES in suction and discharge pipes.

3. RELEASE ALL PRESSURE from pump and piping system.

4. NEVER tighten or loosen clamp while pump is operating.

To avoid dangerous or fatal electrical shock hazard, turn OFF power to

motor before working on pump or motor.

Aside from lubricating trap cover O-Ring, no lubrication or regular mainte-

nance is needed beyond reasonable care and periodic cleaning.

If shaft seal is worn or damaged, repair as follows:

Pump Disassembly/Removing Old Seal

Disconnect power to pump motor.

Be sure gate valves on suction and return piping are closed before start-

ing work.

Release all pressure by opening all vents before starting work.

1. Drain pump by removing drain plugs on bottom of pump body and trap

body.

2. After making sure that there is no pressure in trap body, remove cover (un-

screw by turning counterclockwise).

3. Remove clamp holding pump halves together.

4. Remove pump base mounting bolts, if used. Motor and seal plate assem-

bly can now be pulled away from pump body.

5. Remove five screws and washers holding diffuser to seal plate.

6. Remove motor canopy.

Capacitor voltage can be dangerous. Before proceeding,

short the capacitor terminals together with a screwdriver that has an insu-

lated handle.

Being careful not to touch capacitor terminals, loosen capacitor clamp

and move capacitor to one side.

7. Hold shaft with 7/16" open-end wrench on motor shaft flats.

NOTICE: On models with impeller screw, remove impeller screw (left

hand thread - turn clockwise) and gasket before removing impeller.

Inspect gasket for damage, cracks, etc. Replace if damaged.

8. Unscrew impeller from shaft (turn counterclockwise when facing it).

9. Remove four screws holding seal plate to motor.

10. Place seal plate face down on flat surface and tap out ceramic seat (Fig. 4).

NOTICE: Do not force out heat sink insert (Key No. 7, Pages 12-14).

If insert has moved, pump will leak; see “Installing Insert”, Page 10.

11. Clean seal cavity in seal plate and clean motor shaft.

Hazardous voltage.

Can shock, burn,

or cause death.

Disconnect power

before working

on pump or motor.

Figure 4