3

INSTALLATION

Only qualified, licensed personnel should install pump

and wiring.

Pump mount must:

Be located away from corrosive or flammable chemicals.

Have enough ventilation to maintain air temperature at less

than the maximum ambient temperature rating (Max. Amb.)

listed on the motor model plate. If this pump is installed in

an enclosure/pump house, the enclosure must have ade-

quate ventilation and air circulation to keep the tempera-

ture in the enclosure at or below the motor’s rated ambient

temperature whenever the pump is running.

Be solid - Level - Rigid - Vibration free. (To reduce vibra-

tion and pipe stress, bolt pump to mount.)

Allow pump suction inlet height to be as close to water

level as possible.

Allow use of short, direct suction pipe (To reduce friction

losses).

Allow for gate valves in suction and discharge piping.

Have adequate floor drainage to prevent flooding.

Be protected from excess moisture.

Allow adequate access for servicing pump and piping.

NOTICE:

Use Teflon tape or Plasto-Joint Stik

1

for making

all threaded connections to the pump. Do not use pipe

dope; pipe dope will cause stress cracking in the pump.

NOTICE:

Pump suction and discharge connections have

molded in thread stops. DO NOT try to screw pipe in be-

yond these stops.

Fire and burn hazard.

Modern motors run at

high temperatures. To reduce the risk of fire, do not allow

leaves, debris, or foreign matter to collect around the

pump motor. To avoid burns when handling the motor, let

it cool for 20 minutes before trying to work on it.

Teflon Taping Instructions:

Use only new or clean PVC pipe fittings.

Wrap male pipe threads with one to two layers of Teflon

tape. Cover entire threaded portion of pipe.

Do not

overtighten or tighten past thread stop in pump

port!

If leaks occur, remove pipe, clean off old tape, rewrap

with one to two additional layers of tape and remake the

connection.

NOTICE:

Support all piping connected with pump!

1

Lake Chemical Co., Chicago, Illinois

Piping:

Use at least 2" IPS PVC (51mm) pipe. Increase size if a

long run is needed.

To avoid strains on the pump, support both suction and

discharge pipes independently. Place these supports near

the pump.

To avoid a strain left by a gap at the last connection, start

all piping at the pump and run pipe

away

from the pump.

Never use a suction pipe smaller than pump suction con-

nection.

To avoid airlocking, slope suction pipe slightly upward

toward the pump.

NOTICE:

To prevent flooding when removing pump for

service, all flooded suction systems

must

have gate valves

in suction and discharge pipes.

Fittings:

Fittings restrict flow; for best efficiency use fewest possi-

ble fittings.

Avoid fittings which could cause an air trap.

Pool fittings must conform to International Association of

Plumbing and Mechanical Officials (IAPMO) standards.

Use only non-entrapping suction fitting or double suction.

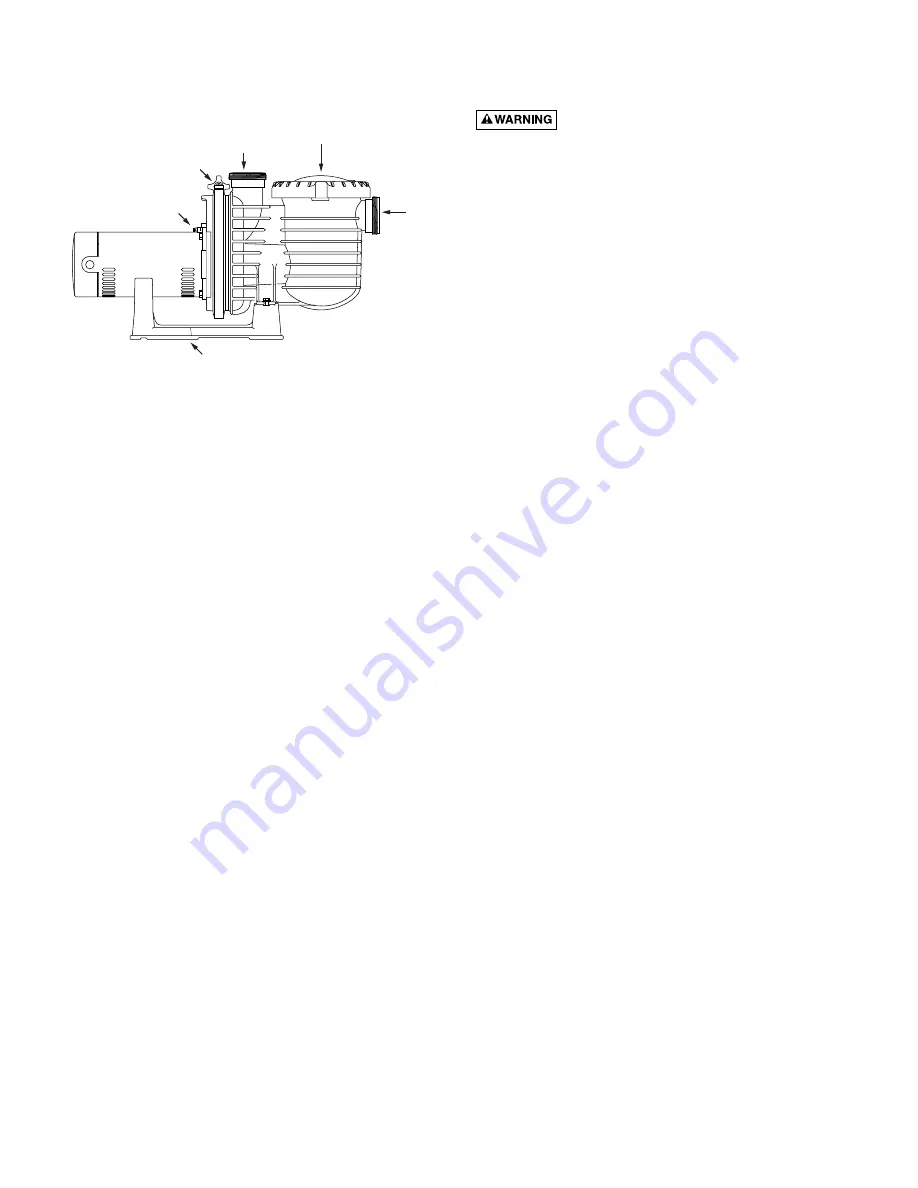

Suction

Port

from

pool or

vacuum

filters

Strainer Basket

cover

Discharge Port

to filter

or pool

Clamp

Knob

Bonding Lug

Pump may be bolted to level

foundation or mounting bracket

4284 1102

Figure 1