6

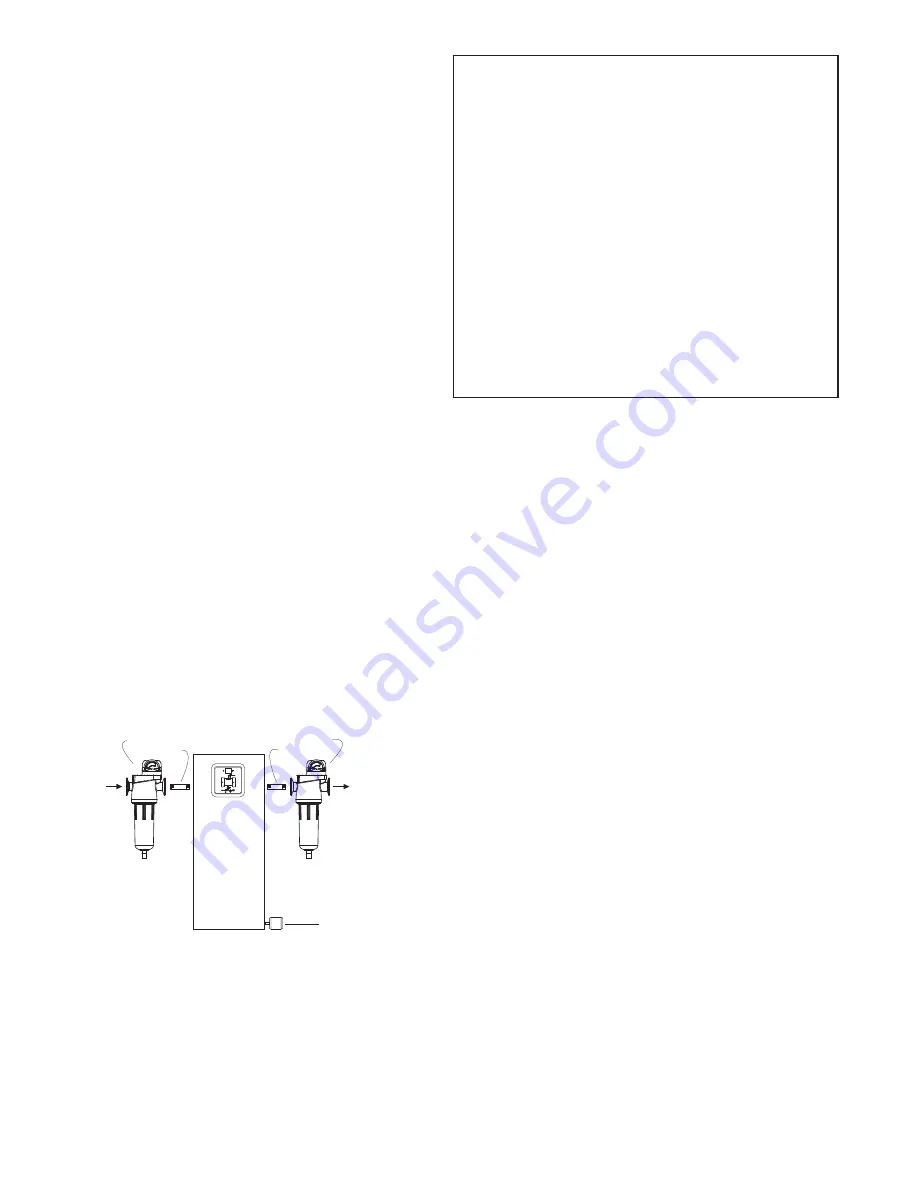

Figure 5

PREFILTER

AFTERFILTER

NIPPLE

NIPPLE

MUFFLER

From

Compressor

To Downstream

Air Lines

P1

P2

D.

Afterfilters

- To ensure downstream air purity (prevent

desiccant dust from traveling downstream) adequate

filtration down-stream of the dryer is required. De-

pending on the degree of purity you require from your

compressed air system, the following filters are recom-

mended:

1.

Air Line Filter

- Use as an afterfilter to remove desic-

cant fines and protect downstream components from

solid particles 1 micron and larger. Filters for finer

solid particle filtration are available.

2.

Oil Vapor Adsorber

- Use as an afterfilter to remove

oil vapor and its subsequent taste and odor and to

protect downstream components from solid particles

0.01 micron and larger.

NOTE:

By-pass lines and isolation valves are recom-

mended so that maintenance work can be performed

without shutting off the air supply.

IMPORTANT:

The compressed air supply inlet should be

periodically checked to ensure that equipment design

specifications are not exceeded. Normally the compressor

installation includes intercoolers, aftercoolers, separators,

receivers, or similar equipment which adequately pretreat

the compressed air supply in order to avoid excessively high

air temperatures and liquid slugging of down-stream equip-

ment.

3.4 PreFilter and AfterFilter Installation

If supplied, install Prefilter and Afterfilter.

NOTE:

When installing, hold bulkhead fitting on dryer with

wrench and thread filter on by hand.

A. Install prefilter (F04-HF-DG1) ahead (upstream) of dryer.

Use nipple supplied to connect filter to inlet port of dryer.

B. Install afterfilter (F04-PF-TG1) downstream of dryer. Use

nipple supplied to connect filter to outlet port of dryer.

NOTE:

Observe arrows on differential pressure gauge to

ensure proper flow direction through filter.

3.5 Wall-mounting

Four holes are provided in rear of cabinet. Attach cabinet

to wall using four (4) screws. User is responsible for select-

ing screws of the appropriate strength and ensuring the wall

mounting surface can safely support the weight of the dryer

(See Section 3.1).

3.6 Piping

Connect air line from compressor to inlet of prefilter or

dryer. Connect downstream air line to outlet of afterfilter or

dryer.

3.7 Electrical connection

Check to see that power supply to dryer is the same as the

power requirements indicated on the identification label.

Install plug into receptacle of proper voltage or hardwire to

pigtails and ground screw inside cabinet.

3.8 Muffler Installation

Install muffler (packaged separately inside dryer shipping

box) to fitting on side of cabinet.

3.9 Moisture Indicator Installation

Install the moisture indicator (shipped separately inside

of cabinet) directly into the pipe line anywhere in air/gas

system where moisture level is to be monitored. If indica-

tor is installed parallel to main line, make sure enough of a

restriction exists in main line to force adequate flow through

indicator.

3.10 Initial desiccant charge

The dryer is shipped complete with desiccant and ready to

operate after piping and electrical connections are made.

CUSTOMER ASSEMBLY

INSTRUCTIONS

These instructions MUST be followed prior to mounting of

dryer enclosure.

1. Connect prefilter and afterfilter to enclosure (if

applicable).

2. Mount dryer.

3. Connect to inlet, outlet, and purge connections. (see

NOTE)

NOTE:

If the equipment is to dry (or reactivate with) a gas

other than air, the outlets of the safety valve, reactivation

gas outlet line, blow down valves, etc. are to piped away

to a safe location (by purchaser). In piping away gas, do

not pipe upward without adequate arrangements to

prevent trapping condensation.

4. Install moisture indicator downstream of dryer outlet (if

applicable).