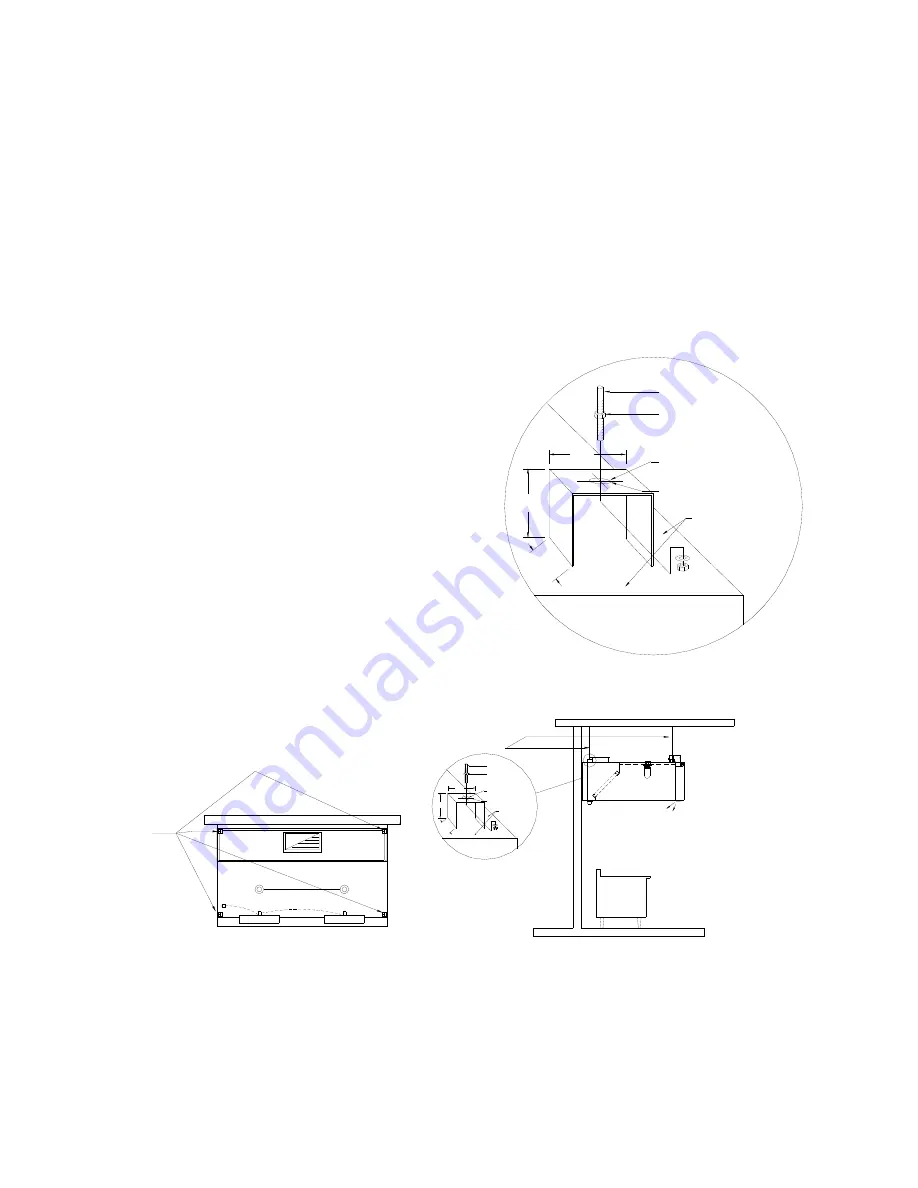

5

2.5"

(FROM FRONT OF HOOD)

TYPICAL HANGER ROD

BRACKET ISOMETRIC

HOOD

2.25"

TOP OF

2.5

HANGER BRACKET

OFFSET 1/2" FROM

EDGE OF HOOD

Ø 17/32"

PRE DRILLED HOLE,

ACCEPTS UP TO

1/2" Ø ROD

HANGER ROD

HANGER ROD NUT

Standard

Dynaflow MJ hood Specification

The unit casing shall be a minimum 18 GA. stainless steel, with No. 4 finish on all exposed surfaces. The hood shall include UL/ULC

listed grease filters mounted in an integral stainless steel rack inclined at 45 degrees. The filter rack shall include a full length stainless

steel grease gutter and grease cup.

The MJ blowers provides ceiling return air to the MJ plenum which discharges out the bottom of the plenum through a s/s perforated

plate along the length of the MJ plenum. The return air is directed through the MJ plenum towards the appliances. MJ blower(s) mounted

on top of the plenum shall be complete with adjustable Triacs, washable filters and wired to a common J-box on top of the hood. A

fusible link fire damper is located below each MJ blower.

The hood shall have ______ incandescent/fluorescent/recessed/incandescent/LED lights evenly spaced along the length of the hood.

Optional Sideflow right and/or left MJ blower assemblies are available.

Dynaflow Installation

The Dynaflow hoods are hung from 4 or more hanging brackets

(depending on the model) mounted on top of the hoods as

indicated on the engineering drawings. The engineering

drawings indicate number and location of the hanger bracket.

All hanger brackets shown on the Spring Air Systems

drawings must be used to support the hood. Spring Air

Systems assumes no responsibility for the field installation

of the any hood.

A typical schematic is shown to the right with recommend

method on installing the hanger rods to the hanger brackets.

The size of the hanger rods, washers and nuts must be

determined by a structural engineer based on hood weight and

site conditions. All hood weight is shown on the Spring Air

Systems section view drawing. The hanger rods must be size to

safely hold the weight of the hood from the structure above.

The structure above must be designed to hold the weight of the

hood. Structural engineers will be required to determine what is

acceptable. The hanger bracket diagram indicates how the rod

is attached to the hood. All hanger rods must be installed

perpendicular to the roof of the hood.

MJ BLOWER

MJ BLOWER

FOUR (4)HANGER

BRACKET LOCATION

MJ DYNAFLOW PLAN VIEW

APPLIANCE

2.5"

(FROM FRONT OF HOOD)

TYPICAL HANGER ROD

BRACKET ISOMETRIC

HOOD

2.25"

TOP OF

2.5

HANGER BRACKET

OFFSET 1/2" FROM

EDGE OF HOOD

Ø 17/32"

PRE DRILLED HOLE,

ACCEPTS UP TO

1/2" Ø ROD

HANGER ROD

HANGER ROD NUT

HANGER ROD BY INSTALLER

MJ DYNAFLOW HANGER BRACKET SECTION VIEW

Wall mounted Dynaflow model FN-B-MJ Hood in Plan and Section View showing hanger rod locations.

Figure 7

Hanger Rod Schematic

Figure 6

Содержание Dynaflow

Страница 23: ...21 Chart No 4...