_____________________________________________________________________________________________

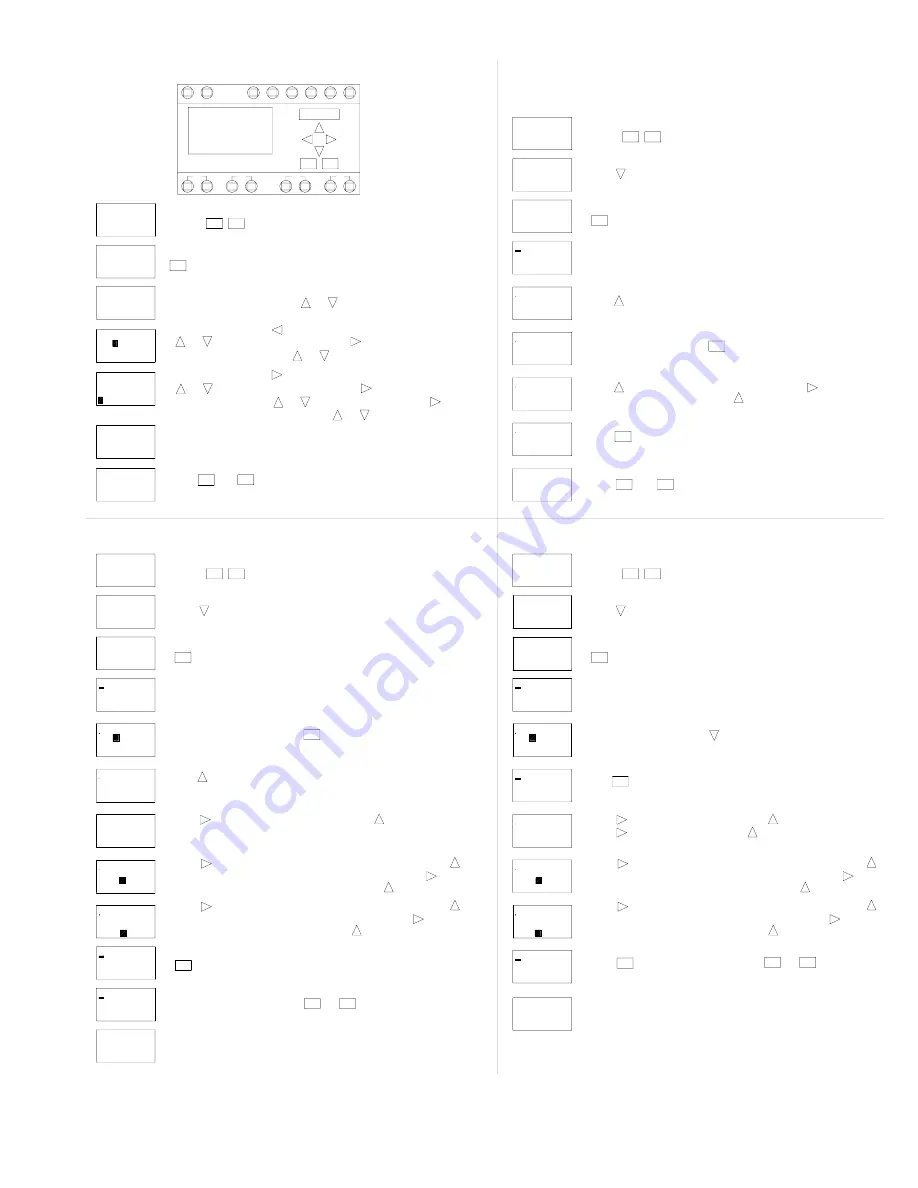

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01

36

Q: 1 2 3 4

Mo 09:14

to program a second (Weekend Operation) or third weekly setting go the the section

"Setting Weekend Operation"

Q: 1 2 3 4

Setting Weekly Fan "ON" and "OFF" times

9. Press to move to the hour that the fan will stop in the evening. Press

to change the hour you want the fan to stop each evening. Press to move

to the minute the the fan will start in the morning. Press to change the minutes.

to change the hour you want the fan to start in each morning. Press to move

8. Press to move to the hour that the fan will start in the morning. Press

fan will not automatically operate on Saturday or Sunday.

not required to operate on that given day. The screen on the left indicates the

the fan will not start automatically any given day.

6. Press to remove Monday from the weekly schedule. The - dash indicates

at 23:00 hours or 11:00 p.m. When the fan shuts off the wash activates.

4. The clock has been factory set to turn the fan on at 6:00 a.m. and off

5. To change the above settings press

7. Press to move to the next day of the week. Press each time the fan is

1. Press these two buttons together

ESC

12. You have completed programming one weekly fan "On" and "Off" cycling. If you wish

11. If your selection is complete press and to return the the operating screen.

to the minute the fan stop in the evening. Press to change the minutes.

B04: No1

D = - TWTF- -

B04: No1

I: 1 2 3 4 5 6

D = MTWTF- -

On = 06: 30

Off = 22: 30

B04: No1

D = MTWTF- -

On = 06: 30

Off = 22: 30

Off = 2 3: 00

On = 06: 30

10.Press

OK

B04: No1

On = 0 6: 00

B04: No1

D = - TWTF- -

Off = 23: 00

B04: No1

On = 06: 00

Off = 23: 00

D = - TWTF- -

Off = 23: 00

On = 06: 00

D = MTWTF-S

B04: No1

D = MTWTFSS

On = 06: 00

Off = 23: 00

Off = 23: 00

On = 06: 00

D = MTWTFSS

B04: No1

>Set Param

Set Clock

3. Press

OK

>Set Clock

Set Param

Mo 09:00

I: 1 2 3 4 5 6

Q: 1 2 3 4

2. Press

ESC

ESC

The cursor will move to M = Monday.

OK

OK

6. You have finished setting the clock.

move to year. Adjust the year by pressing

Adjust the day by pressing

5. To change the date press again. The month will be highlighted. Press

Adjust the minutes by pressing

4. To change the time press once. The hour will be highlighted. Press

3. To change the day of week press

1. Press these two buttons together

ESC

MM. DD. YY

11. 13. 01

I: 1 2 3 4 5 6

Su 11: 25

Set Clock

11. 11. 01

MM. DD. YY

MM. DD. YY

11. 13. 01

Set Clock

Su 11:25

Su 11:25

7. Press

ESC

or

Set Clock

11. 13. 01

MM. DD. YY

Mo 09:00

Set Clock

Set Param

>Set Clock

Mo 09:00

Su 09:00

Q: 1 2 3 4

or

OK

2. Press

I: 1 2 3 4 5 6

to return to the operating screen.

until correct year appears.

Press to move to day.

until correct day appear. Press to

until correct minutes appears.

Press to move to minutes.

until the correct day appears.

or

or

until the correct month appears.

and

OK

or

until the correct hour appears.

OK

or

OK

Q: 1 2 3 4

Mo 09:00

I: 1 2 3 4 5 6

2. Press

OK

3. Press

Set Param

>Set Clock

>Set Param

Set Clock

1. Press these two buttons together

ESC

OK

The wash time has been factory pre-set at 2 minutes.

ESC

5. Press

D = MTWTFSS

Off = 23: 00

On = 06: 00

B04: No1

Ta = 02:00m

T = 02:00m

B01: T

T = 02:00m

B01: T

T = 02:30m

B01: T

Ta = 02:00m

OK

Ta = 02:00m

B01: T

Ta = 02:00m

I: 1 2 3 4 5 6

T = 02:30m

ESC

Q: 1 2 3 4

Mo 09:12

4. The clock has been factory set to turn the fan on at 6:00 a.m. and off

at 23:00 hours or 11:00 p.m. When the fan shuts off the wash activates.

To change these times see section "Programming the SMARTRELAY time clock.

7. Press to change the length the wash in minutes. Press to move to the

9. Press and to return to the operating screen.

the length of wash in seconds. Press to change the seconds.

6. To change the wash time press

8. Press if the wash time is correct.

Setting the Length of Wash

to change the hour you want the fan to start in each morning. Press to move

to the minute the the fan will start in the morning. Press to change the minute

Setting Weekend Operation

8. Press to move to the hour that the fan will start in the morning. Press

to the minute the fan stop in the evening. Press to change the minutes.

to change the hour you want the fan to stop each evening. Press to move

9. Press to move to the hour that the fan will stop in the evening. Press

B04: No2

Off = - - : - -

On = 10: 00

D = - - - - - SS

B04: No2

On = - - : - -

D = - - - - - SS

Off = - - : - -

ESC

1. Press these two buttons together

5. To set Weekend Operation press

6. Press to program the weekend operation.

7. Press five times to move to Saturday. Press to turn fan on Saturday.

4. The clock has been set to turn the fan on at 6:30 a.m. and off at 22:30 hours

or 10:30 p.m. When the fan shuts off the wash activates.

Press once to move to Sunday. Press to turn fan on Sunday.

On = 06: 30

B04: No2

B04: No2

Off = - - : - -

D = - - - - - SS

On = - - : - -

D = - - - - - - -

On = - - : - -

Off = - - : - -

OK

D = MTWTFSS

Off = 23: 00

On = 06: 00

B04: No1

Off = 22: 30

B04: No1

D = MTWTF- -

Set Clock

>Set Param

OK

3. Press

Q: 1 2 3 4

>Set Clock

Set Param

Mo 09:14

I: 1 2 3 4 5 6

2. Press

OK

operating screen.

OK

10. Press

D = - - - - - SS

On = 10: 00

Off = 23: 30

B04: No2

If your selection is complete press and to return the

ESC

ESC

11. You have completed programming weekend fan "On" and "Off" cycling.

Q: 1 2 3 4

Mo 10:24

I: 1 2 3 4 5 6

Setting the Clock Time and Day

I6

I5

I4

I2

I1

I3

N

L

I: 1 2 3 4 5 6

SMART RELAY

Q1

Q2

Mo 09:00

Q: 1 2 3 4

Q3

Q4

ESC

OK