AA

19

0D

AG

Se

ries

Air

Motor

‐

Driven

Tank

Washer

|

1

1/

1

1/

20

10

|

RE

V

.

1

4

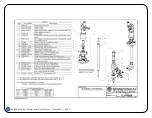

SPECIFICATIONS & OPERATING CONDITIONS

•

LIQUID PRESSURE:

500 PSI (35 BAR) MAX FOR AA190DAG

1000 PSI (69 BAR) MAX FOR AA190DAGH

•

FLOW RATES:

UP TO 20 GPM (76 L/M)

•

PRESSURE DROP AT MAX. FLOW: 40 PSI (2.8 BAR)

•

LIQUID TEMPERATURE:

200 DEGREES F (93 DEGREES C) MAX.

•

AIR PRESSURE TO MOTOR:

16 PSI (0.69 BAR) MAX.

•

AMBIENT TEMPERATURE:

104 DEGREES F (40 DEGREES C) MAX.

•

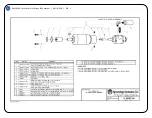

TANK DIAMETER:

FOR AA190DAG

25 FEET (7.6 M) MAX RECOMMENDED

FOR AA190DAGH

34 FEET (10.4 M) MAX RECOMMENDED

•

TANK

COVERAGE 180

DEGREES DOWN COVERAGE

•

SPRAY HEAD AND NOZZLES FIT THROUGH A 4 ¾” (127 MM) DIA. OPENING

TANKS OVER THE SPECIFIED DIAMETERS COULD POSSIBLY BE CLEANED ADEQUATELY

DEPENDING ON THE MAXIMUM TANK DIMENSION, CLEANING SOLUTIONS BEING USED,

TEMPERATURES, SPRAY PRESSURES, FLOW RATES AND THE MATERIAL BEING CLEANED

FROM THE TANK.

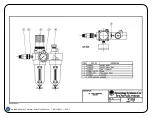

THE TANK CLEANER MAY BE USED WITH PLAIN WATER OR WITH A VARIETY OF

CHEMICALS (COMPATIBLE WITH 316 SS, ETHYLENE PROPYLENE RUBBER, AND CARBON

GRAPHITE FILLED TEFLON

®

). HOWEVER, IF CHEMICALS ARE USED, REVIEW MSDS

SHEETS AND CHEMICAL COMPATIBILITY WITH MATERIAL USED TO CONSTRUCT THIS

PRODUCT. ALSO, THE UNIT SHOULD BE FLUSHED WITH CLEAN WATER AT THE END OF

THE DAY BEFORE THE UNIT IS STORED. A LIQUID LINE STRAINER AHEAD OF THE UNIT IS

RECOMMENDED TO REMOVE LARGE PARTICLES WHICH MAY DAMAGE THE UNIT.