AA

19

0D

AG

Ser

ies

Air

Motor

‐

Driven

Tank

Washer

|

0

8/

1

5/

20

11

|

RE

V

.

1

11

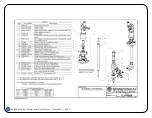

INPORTANT!

EXHAUST CONNECTION IS THE THREADED CONNECTION ON THE LEFT

AS YOU FACE THE MOTOR OPENINGS (MAKRED

“OUT”

). CONNECT THE

LUBRICATOR SUB-ASSEMBLY TO THE AIR INLET CONNECTION OF THE AIR MOTOR.

THE INLET CONNECTION IS THE THREADED CONNECTION ON THE RIGHT AS YOU

FACE THE MOTOR OPENINGS (MARKED

“AIR IN”

). LUBRICATOR SUB-ASSEMBLY

SHOULD BE LOCATED NO FURTER THAN 20 INCHES FROM AIR MOTOR.

ATTACH A COMPRESSED AIR LINE TO THE QUICK CONNECT FITTING OF THE PRESSURE

REGULATOR AND VERIFY THAT THE NOZZLE HUB

ROTATES

CLOCKWISE

WHEN VIEWED

FROM THE NOZZLE HUB END BY APPLYING AIR PRESSURE TO THE MOTOR. CONNECT

THE LIQUID LINE TO THE INLET CONNECTION OF THE LIQUID INLET BODY.

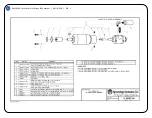

MOUNTING

BOLT OR CLAMP THE UNIT TO THE TANK TO BE CLEANED AS DICTATED BY THE

MOUNTING FLANGE PROVIDED. ADJUSTABLE FLANGES ALLOW EASY POSITIONING OF

THE TANK CLEANING UNIT TO VARIOUS SPRAY DEPTHS FOR MAXIMUM CLEANING

EFFECTIVENESS.

LIQUID INLET CONNECTION

PROPER INSTALLATION REQUIRES LIQUID SUPPLY LINE (PIPE, HOSE, ETC.) MEET OR

EXCEED MAXIMUM WORKING PRESSURE. USE OF PTFE PIPE TAPE OR OTHER

APPROPRIATE SEALANT COMPATIBLE WITH YOUR PROCESS FLUIDS IS HIGHLY

RECOMMENDED FOR LEAK FREE CONNECTIONS.

DANGER

INSTALLATION THE TANK CLEANER WITH INSUFFICIENT CONNECTIONS COULD RESULT

IN LEAKS AND/OR EXPLOSION. IF YOU DO NOT FOLLOW THESE INSTRUCTIONS, YOU MAY

BE KILLED OR SERIOUSLY INJURED.

MECHANICAL CLEARANCES

PROPER INSTALLATION REQUIRES THAT SUFFICIENT CLEARANCE BE MAINTAINED

BETWEEN THE ROTARY HOUSING AND NOZZLES OF THE TANK CLEANING UNIT AND ANY

INTERNAL BAFFLES OR THE WALLS OF THE TANK BEING CLEANED.