IM-P145-02

ST Issue 2

8

3. Installation

Note: Before actioning any installation observe the 'Safety information' in Section 1.

Refering to the Installation and Maintenance Instructions, name-plate and Technical

Information Sheet, check that the product is suitable for the intended installation.

3.1

Check materials, pressure and temperature and their maximum values. If the maximum

operating limit of the product is lower than that of the system in which it is being fitted,

ensure that a safety device is included in the system to prevent overpressurisation.

3.2

Determine the correct installation situation and the direction of fluid flow.

3.3

Remove plastic protective covers from connections.

3.4

If the trap is to discharge to atmosphere ensure that it's to a safe place, the discharging

fluid may be at a temperature of 100

°

C (212

°

F).

3.5

The trap must be fitted with the float arm in a horizontal plane so that it rises and falls

vertically. This applies to all installation flow directions.

3.6

Although the standard flow configuration is right to left (R-L) the connection orientation

can be changed on site by undoing the four cover bolts and moving the cover to the

preferred flow orientation.

Note:

A new gasket must always be fitted.

Warning: The cover gasket contains a thin stainless steel support ring which may

cause physical injury if not handled and disposed of carefully.

3.7

Traps should be fitted below the outlet of the steam system with a small drop leg

immediately preceding the trap - Typically 150 mm (6") see Figure 4. If no drop leg is

allowed then it may be possible (under low load conditions) for steam to flow over the

condensate in the bottom of the pipe and reach the trap.

3.8

Always fit a non-return (check) valve downstream of any steam traps which discharge

into condensate return lines where back pressure is experienced. This is most

commonly caused by a rising condensate line. The check valve will prevent the steam

space flooding when the inlet pressure is reduced or the steam is shut off. Use a suitable

valve such as the Spirax Sarco DCV41, see Figure 4.

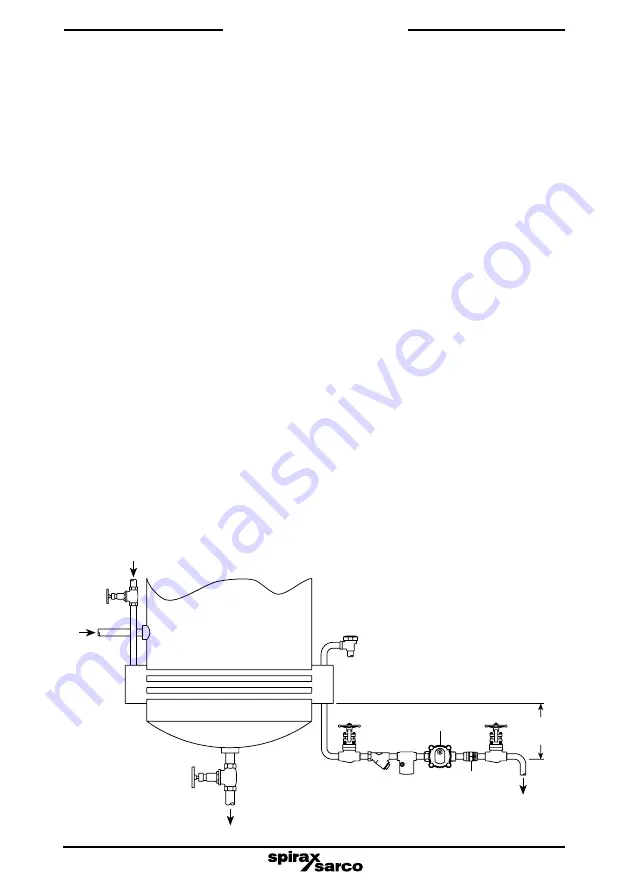

Fig. 4 Evaporator

Heater

Steam in

Product

in

Air vent

Product out

FTS14

150 mm (6")

mimimum

DCV41

Condensate

out

Содержание FTS14

Страница 2: ...IM P145 02 ST Issue 2 2 ...

Страница 12: ...IM P145 02 ST Issue 2 12 ...