Part 4 Maintenance

4.1

Span Calibration using Ambient Air

Calibration involves using a known span gas to match and adjust the oxygen sensor / analyzer

combo to a known value. This can be as simple as using ambient air that tends to be a constant

20.9% which is what we will focus on for section 4.1. For calibrating with a certified SPAN Gas,

please proceed to section 4.2. For a decision on which type of calibration is good for your pro-

cess consult the factory for a recommendation.

Calibration using Ambient Air:

If using ambient air to calibrate the sensor, it is recommended to read

through the calibration procedure prior to performing an air calibration

to make sure all instructions are understood. Consult the factory if any

questions arise.

If the sensor is already installed in the sensor housing, you will need to

connect the gas samples line as noted in section 2.5 or expose the sensor

to ambient air which is typically 20.9%. If using the H3 flow through

sensor housing, you can open up the housing and with two fingers, hold

the sensor to the top portion of the housing, making sure the sensor

contacts are firmly touching the gold pogo pins on the housing. The H1

sensor housing alread has a hole at the bottom of the sensor that exposes

the sensing surface to ambient air.

Let the reading stabilize for about 45 seconds and then proceed to the

following steps in the OMD-501D menu:

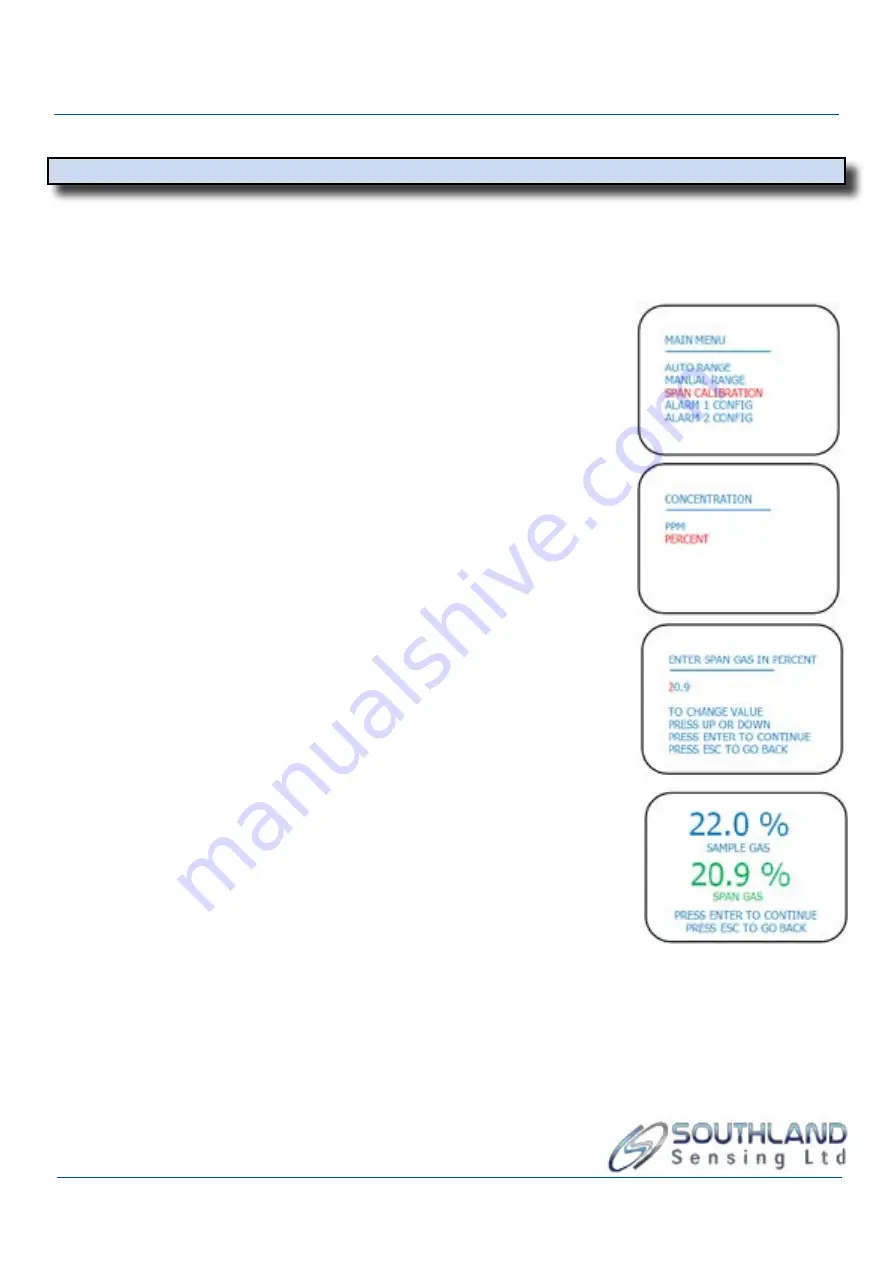

SPAN calibration: To Calibrate the indicator, press MENU key

Use UP/DOWN keys to bring * besides the option

SPAN CAL and press ENTER key:

SPAN CALIBRATION: To calibrate the analyzer, press MENU key

use UP / DOWN keys to bring the cursor to select the SPAN

CALIBRATION selection and press ENTER. Select the PERCENT range

The cursor will show RED next to the digit that can be edited. Use the UP

/ DOWN key to set the required value. You can shift to the next digit

by pressing the ENTER key. For example, if the current reading is 22.0%

and you need to set it to 20.9%, Using the UP and DOWN key to adjust the

value and than the enter key to toggle to the next digit. A final ENTER is

needed to save the value and change the display.

Once ENTER has been pressed, the display will show “PASSED” or “FAILED”. If passed,

promptly put the sensor into a zero or low ppm O2 gas. This will help extend the life of the sen-

sor and speed up the response time. Sensor should be exposed to

ambient air for less than 4 minutes. If failed, repeat calibration steps.