18

SERVICE AND ADJUSTMENTS

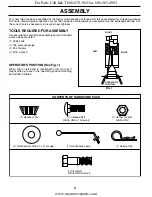

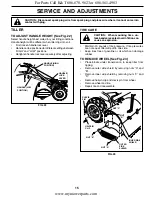

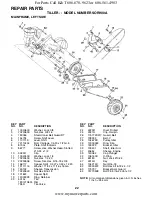

FIG. 29

THROTTLE

CONTROL

CLAMP

SCREW

CASING

AND WIRE

FUEL

TANK

ENGINE

TO ADJUST THROTTLE CONTROL CABLE

(See Fig. 29)

The throttle control has been preset at the factory and

ad just ment should not be necessary. If adjustment is

necessary, proceed as follows:

• With engine not running, move remote throttle control

lever to “FAST” position.

• If throttle lever on engine touches high speed stop, no

further adjustment is necessary. If throttle lever does

not touch high speed stop, continue with adjustment

procedure.

• Loosen cable clamp screw.

• Move throttle lever up until it touches high speed stop,

and hold in this position.

• Tighten cable clamp screw securely.

TO AD JUST CARBURETOR

The carburetor has been preset at the factory and ad just ment

should not be necessary. However, engine per for mance

can be affected by dif fer enc es in fuel, tem per a ture, al ti tude

or load. If the carburetor does need ad just ment, contact

your nearest authorized service center/de part ment

IMPORTANT:

NEVER TAMPER WITH THE ENGINE GOVERNOR,

WHICH IS FACTORY SET FOR PROPER ENGINE SPEED.

OVER SPEED ING THE ENGINE ABOVE THE FACTORY HIGH

SPEED SETTING CAN BE DANGEROUS. IF YOU THINK THE

ENGINE-GOVERNED HIGH SPEED NEEDS ADJUSTING,

CONTACT YOUR NEAREST AUTHORIZED SERVICE CENTER/

DEPARTMENT, WHICH HAS THE PROPER EQUIP MENT AND

EXPERIENCE TO MAKE ANY NEC ES SARY ADJUSTMENTS.

For Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com