LEVIXO 30/50 230V RTS

EN

5

Copyright

©

2017 SOMFY ACTIVITES SA. All rights reserved.

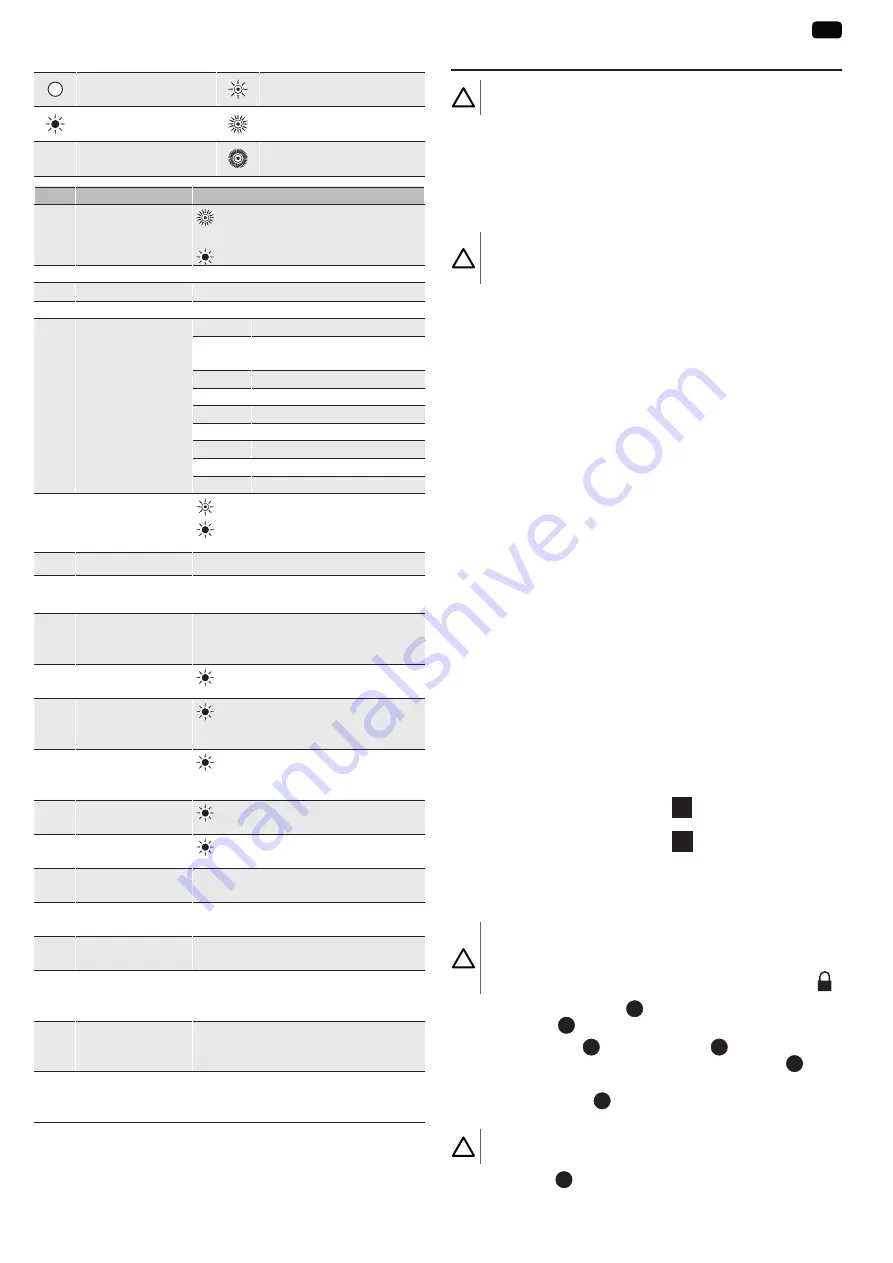

2.5. Description of the circuit board - Fig. 3

Off

Slow flashing

Permanently lit

Rapid flashing

Very rapid flashing

No.

Description

Comments

1

POWER indicator

: Electronic fault (motor thermal cut-

out, etc.)

: Motor on

2

SET indicator

Not used

3

SET button

Not used

4

TIME potentiometer Setting of the automatic timed close

5

Dipswitches

1 - 2

Not used

3

Motor direction of rotation:

installation on left or right

4

Auxiliary output: Lighting

5

Lighting time delay

6

Wire input operating modes

7 - 8 - 9 Motorisation operating modes

10

Safety edge autotest

11

Orange light warning

12

Cell autotest during closing

6

PROG indicator light

: Radio reception

: Awaiting memorisation of a radio

control point

7

PROG button

Radio control points memorised/cleared

8

Removable terminal

block

Terminals 9 to 20: Wiring the accessories

Terminals 21 to 23: Wiring the end limits

9

Non-removable

terminal block (ter-

minals 24 and 25)

Aerial wiring

10

Safety edge input

indicator light

: Fault or activation of the safety edge

11

Cell active during

closing input indica-

tor light

: Fault or photoelectric cells obstructed

12

"Cell active during

opening input"

indicator light

: Fault or photoelectric cells obstructed

13

Total control input

indicator

: Input activated

14

Pedestrian control

input indicator

: Input activated

15

250 V 3.15 AF fuse

Protection of the motor and the 230 V

orange light

16

250V 100 mAT fuse Surge protection for the 24 V accessories

outputs

17

250V 315 mAT fuse Short circuit protection for the 24 V acces-

sories outputs

18

Non-removable

terminal block

(terminals 1 to 3)

230V power supply wiring

19

Removable terminal

block (terminals 4

to 6)

Motor wiring (wired in the factory)

20

Removable terminal

block (terminals 7

and 8)

Wiring for the orange light

3. INSTALLATION

Attention

Check that the ground is level.

͉

͉

The barrier can be installed either directly on the ground or using the

mounting plate provided (recommended for easier levelling).

The barrier is supplied for left-hand mounting.

The door of the housing must be facing inside the property.

3.1. Preparing the base

Attention

Before opening the door of the housing, ensure that the spring is

released by moving the boom to the vertical position.

3.1.1. Foundations with a base plate (optional) and con-

crete foundation - Fig. 4

1) Make a hole in the base suitable for the type of terrain.

2) Use several ducts to route the electrical cables.

3) Place the 4 bolts supplied with the base plate in the final position with

the thread of the bolt facing upwards and weld the heads of the 4 bolts

to the base. Protect the welds with an anti-rust product.

4) Position the plate so that it protrudes from the ground by approximate-

ly 20 mm.

5) Fill the base with concrete, using a spirit level to check the position of

the plate in both directions, and leave the cement to harden.

3.1.2. Foundations without base plate Fig. 5

1) Place the housing on the ground.

2) Mark the mounting holes.

3) Remove the housing.

4) Drill the mounting holes.

5) Insert plugs (not provided) in the mounting holes.

͉

͉

The top surface of the housing is angled slightly to prevent rain water

from collecting. Use a side surface to check that the housing is level.

3.2. Mounting the housing - Fig. 6

Secure the housing using M12 nuts.

3.3. Identifying the barrier’s mounting direction -

Fig. 7

Standing in the middle of the gap and facing the outside:

• if the housing is on the left (Fig. 7

A

), refer directly to the boom

mounting section.

• if the housing is on the right (Fig. 7

B

), refer to the following sec-

tion for right-hand mounting.

3.4. Mounting on the right (opposite of factory

mounting) - Fig. 8

Attention

Before performing any work in the housing, ensure that the spring

is released by moving the boom to the vertical position.

Lock the boom by turning the key to the padlock closed position .

1) Slacken the spring tensioner

1

completely using a Ø19 spanner until

the bolt and nut

2

securing the base of the housing can be removed.

2) Remove the bracket

3

and loosen the bolt

4

using a Ø19 spanner

(with a tightening offset of at least 40 mm) until the lever

5

begins

to rotate.

3) Pull and turn the lever

5

180°. Only one position is possible at 180°,

and is indicated by a notch.

Attention

Be sure not to damage the end limit contacts.

4) Tighten the bolt

4

which immobilises the lever using a torque wrench

set to a torque of approximately 80 Nm.