56

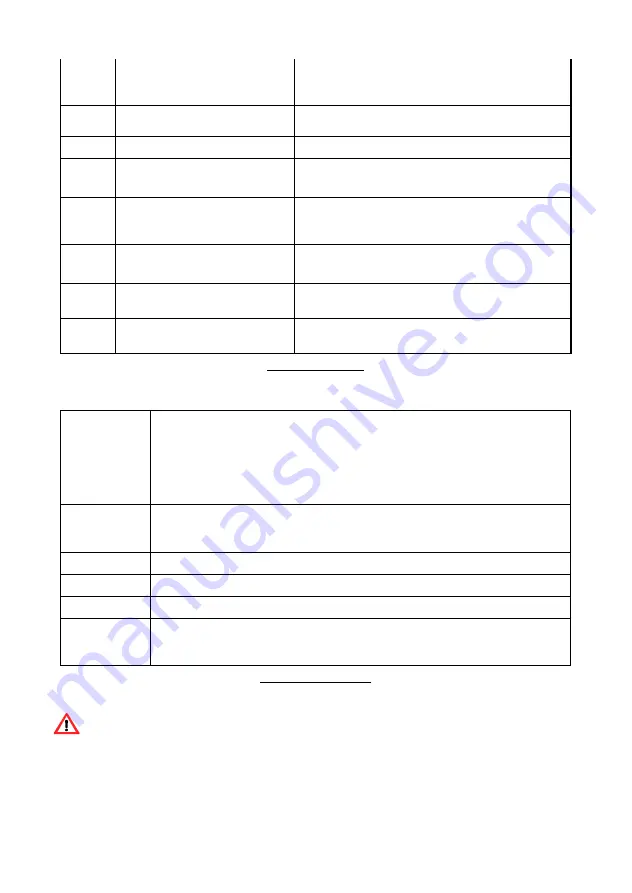

Er23

Boiler probe or inertia tank probe

open

- Check electrical connection.

- Restart the boiler, if the problem persists, contact

technical service.

Er25

Burner cleaning motor broken

- Motor Clean burner broken or blocked.

Er26

Broken cleaning motor

- Motor Clean burner broken or blocked.

Er39

Differential

pressure

sensor

damaged

- Check electrical connection.

- Check for obstructions in the measuring sockets.

Er41

Minimum value of differential

sensor not reached during Check-

up

- Check electrical connection.

- Check for obstructions in the measuring sockets.

Er42

Maximum value of differential

sensor has been exceeded

- Check electrical connection.

Er52

Error I2C I/O modules

- Restart the boiler, if the problem persists, contact

technical service.

Er56

Modified hydraulic installation

- Restart the boiler, if the problem persists, contact

technical service.

Table 3 - List of alarms

Other messages:

Sond

Display the status of the temperature probes. The message appears during

the Check Up phase and indicates that the temperature detected by one or

more probes is equal to the minimum or maximum value (depending on the

probe in question). Check that the probes are not open (detection of the

minimum value of the temperature scale) or short-circuited (detection of

the maximum value of the temperature scale).

Ignition

interlock

Message that appears when the system has been switched off not manually

in the Ignition phase (after Pre-charge): the system only switches off when

it reaches maximum capacity.

Er06

Thermostat Pellets open

Link Error

Lack of communication between the keyboard and the electronic board.

Cleaning On

The system is performing periodic cleaning.

Cleaning

Message indicating that the boiler has more than 2100 operating hours

(parameter T67). Contact your service representative for maintenance.

Table 4 – Other messages

WARNING

THE MAINTENANCE ANOMALY (THE "SERVICE" MESSAGE APPEARS ON THE

DISPLAY) INDICATES THAT THE UNIT HAS EXCEEDED 2100 OPERATING

HOURS. THE UNIT MUST BE SERVICED; ONLY THEN HOUR METER CAN BE

RESTARTED (TECHNICAL MENU) AND THE WARNING CLEARED. THIS

Содержание SZM A PLUS 16 kW

Страница 13: ...9 4 2 Connections views Figure 4 Pellet boilers connections SZM A PLUS 16 24 and 32 kW ...

Страница 23: ...19 Figure 16 Side view of the installation without chimney ...

Страница 25: ...21 Figure 18 Example of flue duct installation B ...

Страница 62: ...58 ...

Страница 63: ...59 ...

Страница 64: ...60 ...