Hydraulic connection

Installation manual

pellet

top

13

6

Hydraulic connection

6.1 Fill-up water requirements

General recommendations for installation

- Fit an upstream filter (<25 µm) to prevent particles

getting into the heating water.

- Position shut-off valves for each section (in buffer

tank, etc.) in order to minimise heating water loss in

the event of repairs or system extensions.

Corrosion

Corrosion is usually triggered by the available oxygen in

the water. This value can be brought into a safe range

with proper planning, design, installation and mainte-

nance of the heating system.

Important:

Pressure maintenance at regular intervals

(system pressure, pressure in the expansion tank)

Formation of scaling

Scaling refers to heating water deposits on the heat

exchanger of the boiler. The cause of scaling is the

presence of limestone in the water. If the value (total

hardness °dH) is too high, the fill-up water must be

treated.

Parameters that play a role in the formation of scaling:

-

System volume

(the bigger it is, the less total hard-

ness is permissible, e.g. buffer tank fitted, boiler cas-

cade, etc.).

-

Boiler output

(the bigger it is, the less total hardness

is permissible).

To determine the total allowable hardness for the

system, the specific water content must be deter-

mined

:

System volume

(litres)

=

Spec. water content of the

system

(l/kW)

Boiler output (kW)

Example:

1166

litres

= 46.64 l/kW

25 kW

Overall output of heat supply

German hard-

ness

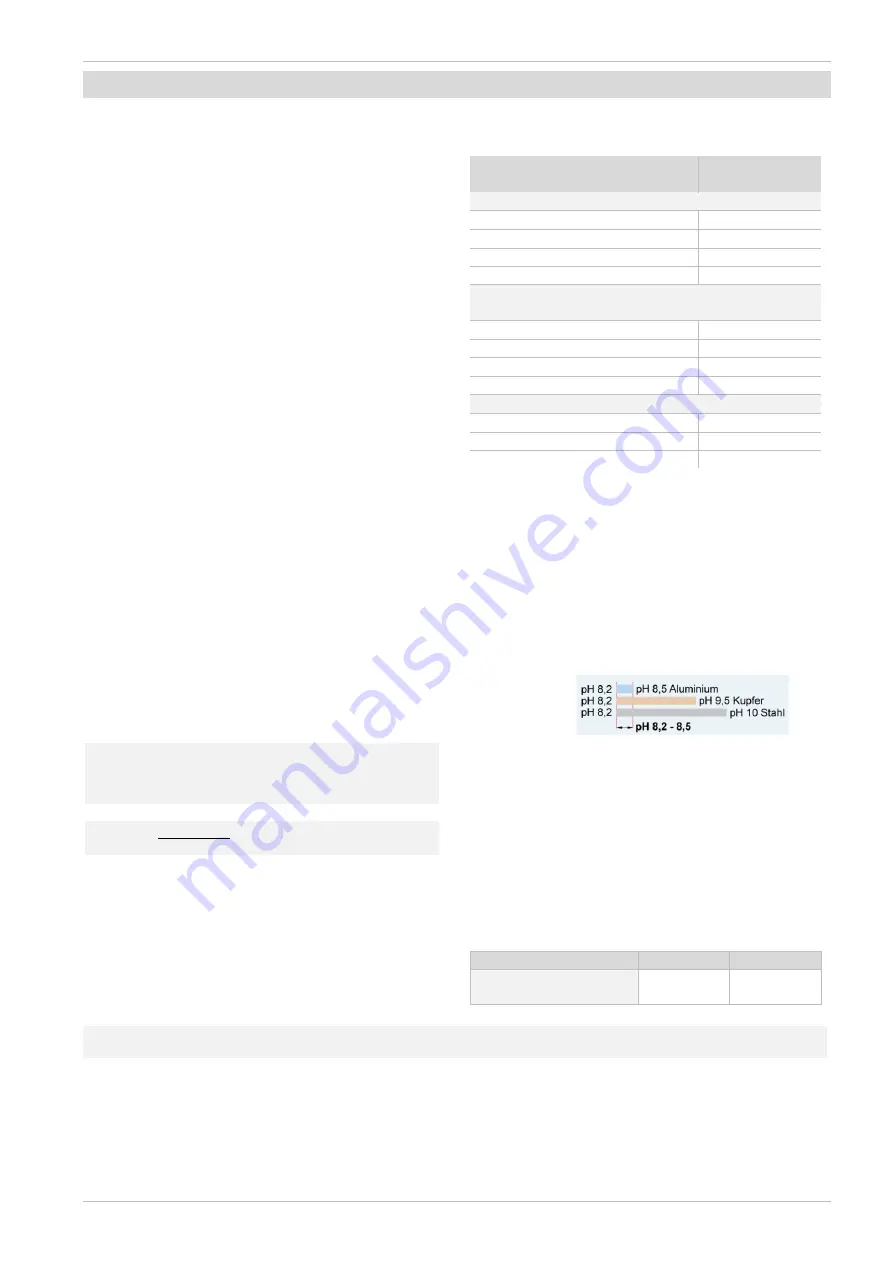

Specific water content of the system <20 l / kW

≤ 50 kW

≤ 16.8 °dH

> 50

kW to ≤ 200 kW

≤ 11.2 °dH

> 200 kW to ≤ 600 kW

≤ 5.6 °dH

> 600 kW

≤ 2.8 °dH

Specific water content of the system ≥ 20 l/kW, but

< 50 l/kW

≤ 50 kW

≤ 11.2 °dH

> 50 kW to ≤ 200 kW

≤ 5.6 °dH

> 200 kW to ≤ 600 kW

≤ 2.8 °dH

> 600 kW

≤ 0.6 °dH

Specific

water content of the system ≥ 50 l/kW

≤ 50 kW

≤ 5.6 °dH

> 50 kW to ≤ 200 kW

≤ 2.8 °dH

> 200 kW

≤ 0.6 °dH

In the event of exceeding the above values, the fill-

up water is to be treated. Recommended action:

Softening (e.g., ion-exchange resin, the same pro-

cedure as for drinking water softening).

Check the pH of the fill-up water

- In the normal case (mixed installation) no

measures are required to influence the pH (con-

trol: value should be in the range of 8.2 to 10).

Exception: If aluminium materials are used in the

heating system, a pH from 8.2 to 8.5 must be met

(pH> 8.5 increased corrosion tendency).

- If the value is significantly less than <8.2 after

filling, then check again after 8-12 weeks

- If there is no increase in value, then add 10 g/m³

trisodium phosphate (Na3PO4) or 5 g/m³ sodium

hydroxide (NaOH).

- Allow 2-4 weeks of operation before further cor-

rections.

Electrical conductivity

Recommendation: Low salt driving (filling with de-

mineralised water), see VDI 2035 sheet 2.

Low salt

Salty

Electrical conductivity

at 25°C

< 100

µS/cm

100

– 1500

µS/cm

Compliance with the above mentioned standards / regulations must be ensured by the heating engineer.

Содержание pellet top touch 35

Страница 25: ...Annex Installation manual pellettop 25 Boiler cascade solution with different storage conveying system...

Страница 26: ...Annex 26 Installation manual pellettop 9 6 Commissioning log...

Страница 27: ...Annex Installation manual pellettop 27...

Страница 28: ...Annex 28 Installation manual pellettop 9 7 Customer service order form...

Страница 29: ...Annex Installation manual pellettop 29...

Страница 30: ...Annex 30 Installation manual pellettop...

Страница 31: ...Annex Installation manual pellettop 31...