19

MAINTENANCE

7- MAINTENANCE

IN CASE OF MALFUNCTION, STOP THE PLANTER IM-

MEDIATELY AND REMOVE THE IGNITION KEY. LEAVE

THE TRACTOR AND VISUALLY INSPECT AND EVALUA-

TE THE EXTENT OF THE PROBLEM. PERFORM THE

REQUIRED OPERATIONS ON THE PLANTER BEFORE

RESTARTING IT.

MAINTENANCE OPERATIONS MUST BE PERFORMED

IN PROPERLY EQUIPPED GARAGES BY QUALIFIED PER-

SONNEL.

NO REPAIRS SHOULD BE PERFORMED WITHOUT THE

NECESSARY SKILLS AND KNOWLEDGE. IT IS ESSEN-

TIAL THAT THE INSTRUCTIONS DETAILED IN THIS

MANUAL ARE STRICTLY FOLLOWED. IF THESE INS-

TRUCTIONS ARE MISSING, PLEASE CONTACT THE

PLANTER’S PROVIDER OR QUALIFIED PERSONNEL.

IN ORDER TO PERFORM MAINTENANCE OR REPAIR

OPERATIONS TO THE PLANTER, IT IS ESSENTIAL TO

USE PROPER

PERSONAL PROTECTIVE EQUIP-

MENT

(PPE): SAFETY BOOTS AND GLOVES, HEARING

PROTECTION, DUST MASK AND PROTECTIVE GLAS-

SES).

IT IS RECOMMENDED TO AVOID WEARING LOOSE

CLOTHING SINCE IT MAY BECOME TANGLED WITH

THE PLANTER’S MOVING PARTS.

Before performing any task on the machine, it is essential to take into

account the following factors:

- Maintaining or repairing the planter should be performed on a

flat and compact ground. Before starting any of these tasks, the

tractor’s engine must be turned off and the ignition key removed.

- The chosen device to raise the planter needs to be appropriate for

the operations to be performed. Please ensure that all safety regu-

lations are observed.

- Always use appropriate protective equipment for any task to be

performed.

- In case compressed air is used to clean the planter, you are required

to wear protective glasses and mask.

- If any operation needs to be performed on a part of the machine

which is at more than 1,5 metres height from the ground, check if it

is possible to reach this part using the planter’s access points. If not

possible, use either a ladder or a platform which is in accordance

with the current safety regulations.

- Prolonged and/or repetitive skin contact with fuel and lubricants

is harmful. In case these products come accidentally into contact

with the eyes or other sensitive parts, wash well the affected parts

with clean water. In case of ingestion, contact the medical services

immediately.

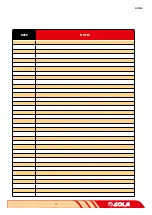

7.1 CHECKING FREQUENCY

The periodicity of the check-ups indicated below is solely for orien-

tation purposes. It may suffer variations depending on the type of

service, use of the machine and conditions of use.

- BEFORE STARTING THE SOWING SEASON:

Check the general operation of the planter. Perform this check

without any products inside the hopper.

Check that the plastic components of the planter are in good condi-

tion. The wear of this material due to natural ageing or to the presen-

ce of rodents causes damages to these components.

Check that the mechanical components are in good condition and

not rusty.

Clean the parts of the machine which are permanently in contact

with seeds or fertilizers, such as hopper and metering unit.

Check that the signal lamps work properly.

Check that the unions and the ducts of the hydraulic system do not

show oil leaks.

- DAILY:

Empty and clean with air pressure both the hopper and the dispen-

ser of residual products that may remain after finishing the work

shift.

Check that the metering unit and the air circuit do not contain any

residue (such as seed or fertilizer residue, dust, etc). Residue accumu-

lation may damage the air circuit.

- END OF SOWING SEASON

Empty and clean with air pressure both the hopper and the dispen-

ser, making sure that there are no residual products,

If washing the machine, make sure no residual products remain, as

they may damage the machine if left to dry.

Repaint any metallic component which has lost its paint due to wear.

To store the planter properly, cover it with tarpaulin and keep it in a

dry place.

Thoroughly check all components of the planter and replace the

ones which are damaged or worn.

A careful maintenance of the machine ensures proper functioning

and long service life of the machine.

BEFORE PERFORMING THESE OPERATIONS, THE

PLANTER’S ENGINE MUST BE TURNED OFF AND THE

IGNITION KEY REMOVED.

The next table shows the maintenance operations to be performed

on the machine along with their (GUIDANCE) frequency:

AFTER THE FIRST 10 HOURS OF WORK, TIGHTEN THE

SCREWS.

Содержание AURA-3215

Страница 1: ...WWW SOLAGRUPO COM AURA 3215 Pressurized hopper MAINTENANCE AND DOSAGE STARTING MANUAL ...

Страница 4: ...4 ...

Страница 22: ...22 NOTES NOTES DATE NOTES ...

Страница 23: ...23 NOTES DATE NOTES ...

Страница 24: ......