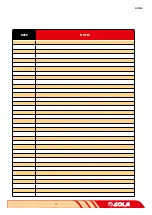

13

DOSAGE

WHEN EXTRACTING THE ENDLESS, BE CAREFUL NOT

TO LOSE THE O-RINGS OF THE AXLE. MOUNT THE O-

RING CORRECTLY AFTER ASSEMBLING THE ENDLESS.

DON’T FORGET THE LATCH

“R”

OR THE DISPENSER

WON’T WORK.

5.1.3 TRANSFILLING DISPENSER

This dispenser only works as TRANSFILLING of seed or fertilizer in low

doses (20 Kg/min).

5.2 CALIBRATION TEST

Before working with the machine, a flow test must be performed in

order to determine the dose to be distributed. For that, you must:

1-

Assembly the distributor’s roller or change the endless, in function

of the chosen dosage graph.

2-

Place the chopper in working position.

CLOSED POSITION

WORK POSITION

3-

Open the calibration cap acting over the 2 closures.

4-

Put the supplied sack or any other container below the calibration

output.

5-

Act over the PERFORMER or ISOBUS controller of the machine to

perform the test, see specific PERFORMER or ISOBUS manual.

6-

Weigh the material in the sack or container and verify that it’s the

desired dose, if not increase or decrease the dose through the

controller or by changing the number of sectors of the roller or

endless (depending on the model).

WHENEVER THE DISTRIBUTOR’S CONFIGURATION IS

MODIFIED OR PRODUCTS ARE SWITCHED, YOU MUST

PERFORM A CALIBRATION TEST.

THE CONTROLLER’S SCREEN HAS A BAR THAT INDICA-

TES THE ENGINE’S LOADING RANGE. IT MUST WORK

WITHIN 60% TO 80% OF ITS CAPACITY.

60%- 80%

WHEN FINISHING THE CALIBRATION TESTS, CLOSE

THE CALIBRATION CAP AGAIN.

Содержание AURA-3215

Страница 1: ...WWW SOLAGRUPO COM AURA 3215 Pressurized hopper MAINTENANCE AND DOSAGE STARTING MANUAL ...

Страница 4: ...4 ...

Страница 22: ...22 NOTES NOTES DATE NOTES ...

Страница 23: ...23 NOTES DATE NOTES ...

Страница 24: ......