10

Section 3 - OPERATING INSTRUCTIONS

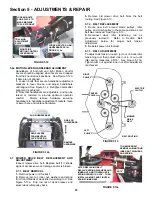

ROLL RELEASE: To roll the machine without the

engine running, pressure within the hydraulic pumps

must be released. There is a hydraulic pressure relief

valve on the upper side of each pump that is used to

release the pressure. Use a wrench to rotate both relief

valves counter clockwise two full turns to open. After

rolling machine, both relief valves must be rotated

clockwise to close valves and tighten securely before

operating machine. Machine will not move if relief

valves are open. See Figure 3.4.

FIGURE 3.4

WARNING

DO NOT disengage the hydro transmission and coast

down slopes. DO NOT use Roll Release Control to

disengage the hydro transmission unless machine

motion can be controlled and engine is off.

3.2 STARTING & STOPPING – ENGINE, BLADES,

PARKING BRAKE

3.2.1. STARTING ENGINE

When the ignition key is turned the engine will not

start or turn over unless the blade switch is pushed

in to the “OFF” position and the motion control

levers are in the neutral lock position. Always

engage parking brake before starting engine.

1.

Complete pre-start checklist.

2.

Sit in operator’s seat.

3.

Push blade switch in to “OFF”, blades

disengaged position and engage parking brake.

See Figure 3.2.

4.

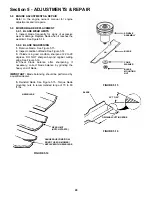

Move choke control forward to choke position to

start a cold engine. See Figure 3.5.

5.

Move engine speed control to the Rabbit “FAST”

position. See Figure 3.5.

6.

Turn key to the start position until engine starts.

See Figure 3.6.

NOTE:

If after 5 seconds of cranking the engine

does not start, release the key. Attempt starting

again after waiting for approximately 20 seconds.

7.

After engine starts, move the choke control to

the “OFF” or no choke position. Allow a brief warm-

up until engine runs smooth.

FIGURE 3.5

CHOKE

CONTROL

ENGINE

SPEED

CONTROL

KEY

SWITCH

SHOWN FROM OPERATOR’S VIEW POINT

ROTATE RELIEF VALVE

COUNTERCLOCKWISE

TO RELIEVE PRESSURE

RELIEF VALVE

MOTION CONTROL LEVERS

SHOWN IN THE NEUTRAL

LOCK POSITION

Содержание CZT19480KWV, CZT19481KWV, HZT2

Страница 33: ...33 PRIMARY MAINTENANCE...

Страница 34: ...34 PRIMARY MAINTENANCE...

Страница 35: ...35 PRIMARY MAINTENANCE...

Страница 36: ...36 PRIMARY MAINTENANCE...

Страница 38: ...38 NOTES...

Страница 39: ...39 NOTES...