4

Ser

vice

MAINTENANCE

Before servicing or making adjustments to machine, stop engine and remove

key from ignition.

Use all procedures and parts prescribed by the manufacturer's. Read the en-

gine manual before operation.

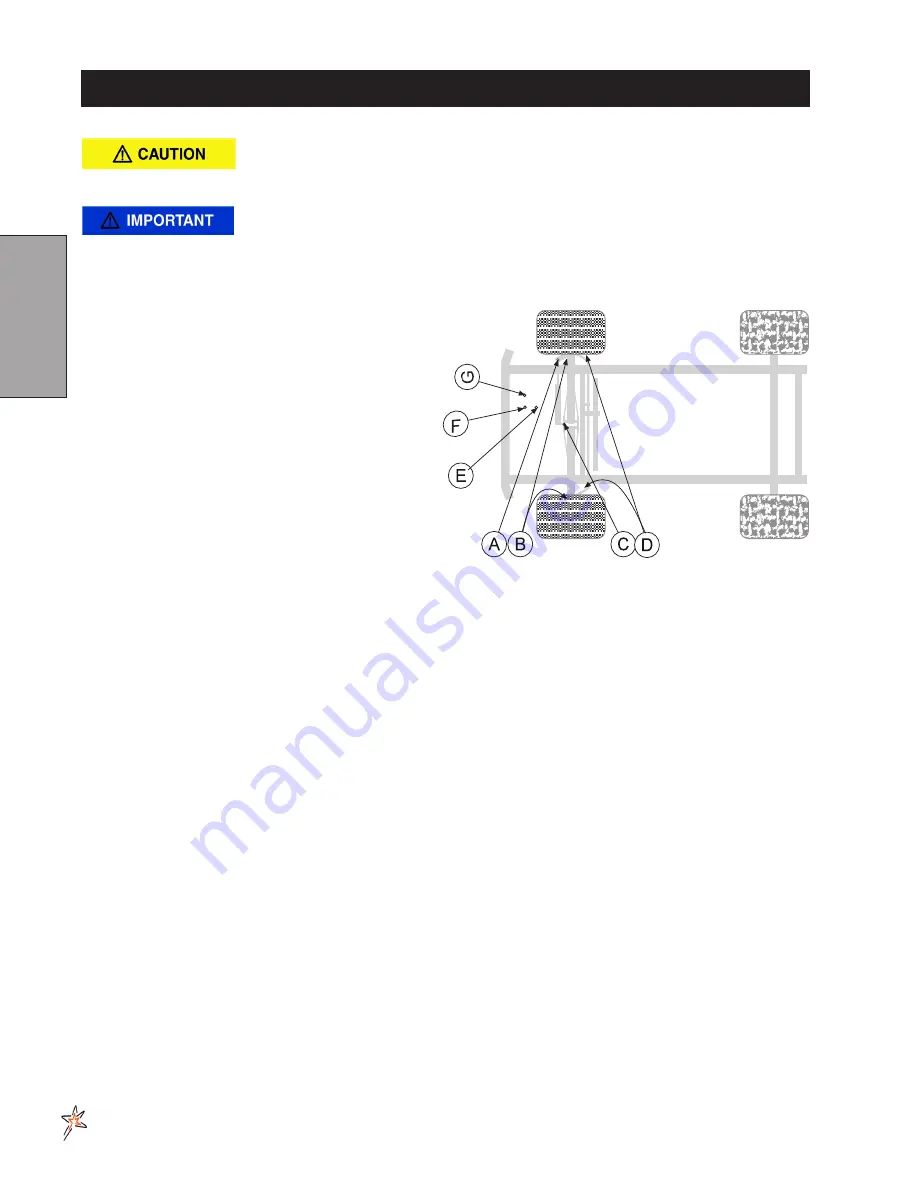

LUBRICATION

Use No. 2 General purpose lithium base grease and lubricate every 100 hours. The Spray Star 1000 has 10

grease fittings.

A. One on the rod end of hydraulic cylinder.

B. One on each the right and left spindles.

C. One on the center front pivot.

D. One on each end of tie rod.

E. One on the pedal relay.

F. One on the forward pedal.

G. One on the reverse pedal.

ELECTRICAL CONNECTIONS

Use dielectric grease on all electrical connections.

AIR CLEANER

1. Loosen cover retaining snaps and remove

cover.

2. Remove pre-cleaner from paper element.

3. Check paper element. Replace element as necessary.

4. Wash pre-cleaner in warm water with detergent. Rinse pre-cleaner thoroughly until all traces of deter

-

gent are eliminated. Squeeze out excess water (do not wring). Allow pre-cleaner to air dry.

5. Saturate pre-cleaner with new engine oil. Squeeze out all excess oil.

6. Reinstall pre-cleaner over paper element.

7. Reinstall air cleaner cover. Secure cover with cover retaining knob.

WHEEL MOUNTING PROCEDURE

1. Set park brake. Turn machine off and remove key.

2. Block wheel on opposite corner.

3. Loosen nuts slightly on wheel to be removed.

4. Jack up machine being careful not to damage underside of machine.

5. Place wheel on hub lining up bolt holes.

6. Torque to 64-74 ft/lb (87-100Nm) using a cross pattern. Re-torque after first 8 hours and every 250

hours thereafter.

7. Lower machine to ground and remove blocks and jack.

TIRE PRESSURE

Caution must be used when inflating a low tire to recommended pressure. Over inflating can cause tires to

explode. All tires should be 20 psi (1.4bar). Improper inflation will reduce tire life considerably.

Содержание Spray Star 1000

Страница 12: ...10 Diagrams WIRING DIAGRAM...

Страница 14: ...12 Diagrams HYDRAULIC DIAGRAM...

Страница 16: ...14 Parts BODY FRAME DRAWING...

Страница 18: ...16 Parts NOSE CONE DRAWING...

Страница 20: ...18 Parts FRONT AXLE DRAWING...

Страница 22: ...20 Parts SEAT CONSOLE AND ROPS DRAWING...

Страница 24: ...22 Parts FUEL TANK DRAWING...

Страница 26: ...24 Parts OIL TANK OIL FILTER OIL COOLER DRAWING...

Страница 28: ...26 Parts FOOT PEDAL LINKAGE DRAWING...

Страница 30: ...28 Parts PUMP DRAWING...

Страница 32: ...30 Parts ENGINE DRAWING...

Страница 34: ...32 Parts PARK BRAKE DRAWING...

Страница 36: ...34 Parts REAR AXLE DRAWING...

Страница 38: ...36 Parts TANK DRAWING TURBO QUAD AGITATOR DRAWING...

Страница 40: ...38 Parts 15 301 ORBITROL DRAWING...

Страница 56: ...56 Accessories DYNAJET MODULE MOUNTS...

Страница 58: ...58 Accessories WIRING TEEJET AEROS SYSTEM...

Страница 59: ...59 Accessories WIRING TEEJET DYNA JET SYSTEM...

Страница 62: ...62 Accessories 10 648 3 WAY MANUAL VALVE DRAWING...

Страница 68: ...68 Accessories 17 585 18 SMITHCO SUPER BOOM...

Страница 70: ...70 Accessories 17 585 18 SMITHCO SUPER BOOM...

Страница 74: ...74 Accessories 17 601 15 HD BOOM DRAWING...

Страница 76: ...76 Accessories 17 601 15 HD BOOM DRAWING...

Страница 84: ...84 Accessories 16 906 ELECTRIC HOSE REEL DRAWING...

Страница 88: ...88 Accessories 1002D 1008D HOSE REEL PLUMBING DRAWING 1011D HOSE REEL PLUMBING DRAWING...

Страница 92: ...92 Accessories 10 378 FOAM MARKER FOR 1000 DRAWING WIRING DRAWING...

Страница 94: ...94 Accessories 10 378 FOAM MARKER DRAWING...

Страница 96: ...96 Accessories FOAMER NOZZLE MOUNT DRAWING...

Страница 98: ...98 Accessories 14 291 FOAMER REPLACEMENT PARTS...

Страница 102: ...102 Accessories 10 417 CHEMICAL CLEAN LOAD TROUBLE SHOOTING...

Страница 104: ...104 Accessories 15 620 CHEMICAL CLEAN LOAD DRAWING...

Страница 108: ...108 Reference NOTES...