4

Service

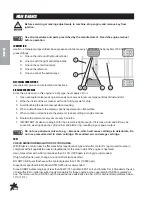

MAINTENANCE

Before servicing or making adjustments to machine, stop engine and remove key from

ignition.

Use all procedures and parts prescribed by the manufacturer's. Read the engine manual

before operation.

LUBRICATION

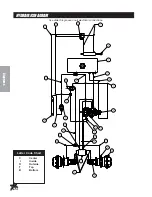

Use No. 2 General purpose lithium base grease and lubricate every 100 hours. The Spray Star 3180 has 7

grease fittings.

A. One on the rod end of hydraulic cylinder.

B. One on each the right and left spindles.

C. One on the center front pivot.

D. One on the idler arm.

E. One on each of the pedal relays.

ELECTRICAL CONNECTIONS

Use dielectric grease on all electrical connections.

AIR CLEANER ON ENGINE

Since the air cleaner on this engine is a dry type, never apply oil to it.

1. Open evacuator valve (see engine manual) once a week to remove large particles of dust and dirt.

2. Wipe the inside of the air cleaner with a cloth if it gets wet or dirty.

3. Avoid touching the element except when cleaning.

4. When dust adheres to the element, gently tap element on flat surface.

5. When carbon or oil adheres to the element clean according to engine manual.

6. Replace the element every year or every 6 months.

7. IMPORTANT - Make sure wing bolt for the element is tight enough. If it is loose, dust and dirt may be

sucked in, wearing down the cylinder liner and piston ring, resulting in poor power output.

Do not use petroleum solvents, e.g.., kerosene, which will cause cartridge to deteriorate. Do

not use pressurized air to clean cartridge. Pressurized air can damage cartridge.

FUEL

CHECK EMISSION REGULATIONS OF YOUR AREA

With Emission control now in effect diesel fuel specification type and sulfur content % (ppm) used must be in

compliant with all applicable emission regulations for the area in which the engine is operated.

Use of diesel fuel with sulfur content less than 0.10% (1000 ppm) is strongly recommended.

If high sulfur fuel is used, change oil and oil filters twice as often.

DO NOT USE Fuels that have sulfur content greater than 1.0% (10000 ppm).

Diesel fuels specified in EN 590 or ASTM D975 are recommended.

Since KUBOTA diesel engines of less than 56kW (75 hp) utilize EPA Tire 4 and Interim Tier 4 Standards, the use

of low sulfur fuel or ultra low sulfur fuel is mandatory for these engines, when operated in US EPA regulated ar-

eas. Therefore, use No.2-D S500 or S15 diesel fuel as a alternative toe No. 2-D for ambient temperatures below -

10°C (14° F).

Содержание 30-000-C

Страница 13: ...11 Service NOTES ...

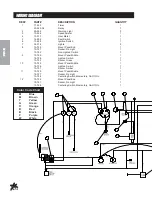

Страница 18: ...16 Parts BODY FRAMEDRAWING ...

Страница 20: ...18 Parts NOSECONEDRAWING ...

Страница 22: ...20 Parts NOSECONEDRAWING ...

Страница 24: ...22 Parts LINKAGEDRAWING ...

Страница 26: ...24 Parts FRONTAXLEDRAWING ...

Страница 28: ...26 Parts OIL FUELTANKDRAWING ...

Страница 30: ...28 Parts SEATPANELDRAWING ...

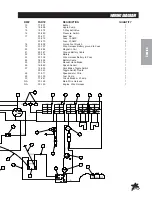

Страница 32: ...30 Parts ENGINEANDPUMPS DRAWING ...

Страница 34: ...32 Parts ENGINEANDPUMPS DRAWING ...

Страница 36: ...34 Parts COOLERANDEXHAUSTDRAWING ...

Страница 38: ...36 Parts REARWHEELDRIVEDRAWING ...

Страница 40: ...38 Parts TANKDRAWING ...

Страница 42: ...40 Parts TURBO QUADAGITATORDRAWING ...

Страница 44: ...42 Parts 15 301ORBITROLDRAWING ...

Страница 48: ...46 Parts 30 102EATONPUMPDRAWING ...

Страница 50: ...48 Parts 30 102EATONPUMPDRAWING ...

Страница 52: ...50 Parts 30 101EATONMOTORDRAWING ...

Страница 54: ...52 Parts 30 099 AUBURN POWERWHEEL DRAWING ...

Страница 56: ...54 Accessories 3182PLUMBINGDRAWING RAVEN440 15 818 75 Fitting O ring 15 817 50 Fitting O ring ...

Страница 58: ...56 Accessories 3184PLUMBINGDRAWING RAVEN203 15 818 75 Fitting O ring 15 817 50 Fitting O ring ...

Страница 66: ...64 Accessories CONTROLS3182SYSTEMDRAWING RAVEN 440 ...

Страница 68: ...66 Accessories CONTROLS3184SYSTEMDRAWING RAVEN 203 ...

Страница 70: ...68 Accessories WIRING 3185 3186 SYSTEM ENVIZIO PRO II SHARP SHOOTER W RATE SYNC ...

Страница 72: ...70 Accessories WIRING3187 3188SYSTEM RAVEN440 SHARPSHOOTER ...

Страница 76: ...74 Accessories 15 743MANIFOLDVALVEDRAWING ...

Страница 78: ...76 Accessories 17 58020 HEAVYBOOM ...

Страница 80: ...78 Accessories 17 58020 BOOMDRAWING ...

Страница 84: ...82 Accessories 17 585 18 HEAVYBOOM ...

Страница 86: ...84 Accessories 17 585 18 HEAVYBOOM ...

Страница 90: ...88 Accessories 30 010ELECTRICHOSEREELDRAWING ...

Страница 94: ...92 Accessories HOSEREELMOUNT DRAWING ...

Страница 96: ...94 Accessories 30 004FOAMMARKERDRAWING WIRINGDRAWING ...

Страница 98: ...96 Accessories 30 004FOAMMARKERDRAWING ...

Страница 100: ...98 Accessories FOAMER NOZZLEMOUNT HOSEGUARDMOUNTDRAWING ...

Страница 103: ...101 Accessories NOTES ...

Страница 106: ...104 Accessories 30 006FRESHWATERTANKDRAWING ...

Страница 110: ...108 Accessories 15 620CHEMICALCLEANLOAD PARTSDRAWING ...