Page 8

SERIES 28HE STEAM BOILER INSTALLATION AND OPERATION INSTRUCTIONS

2. Carefully place the back section in position on the

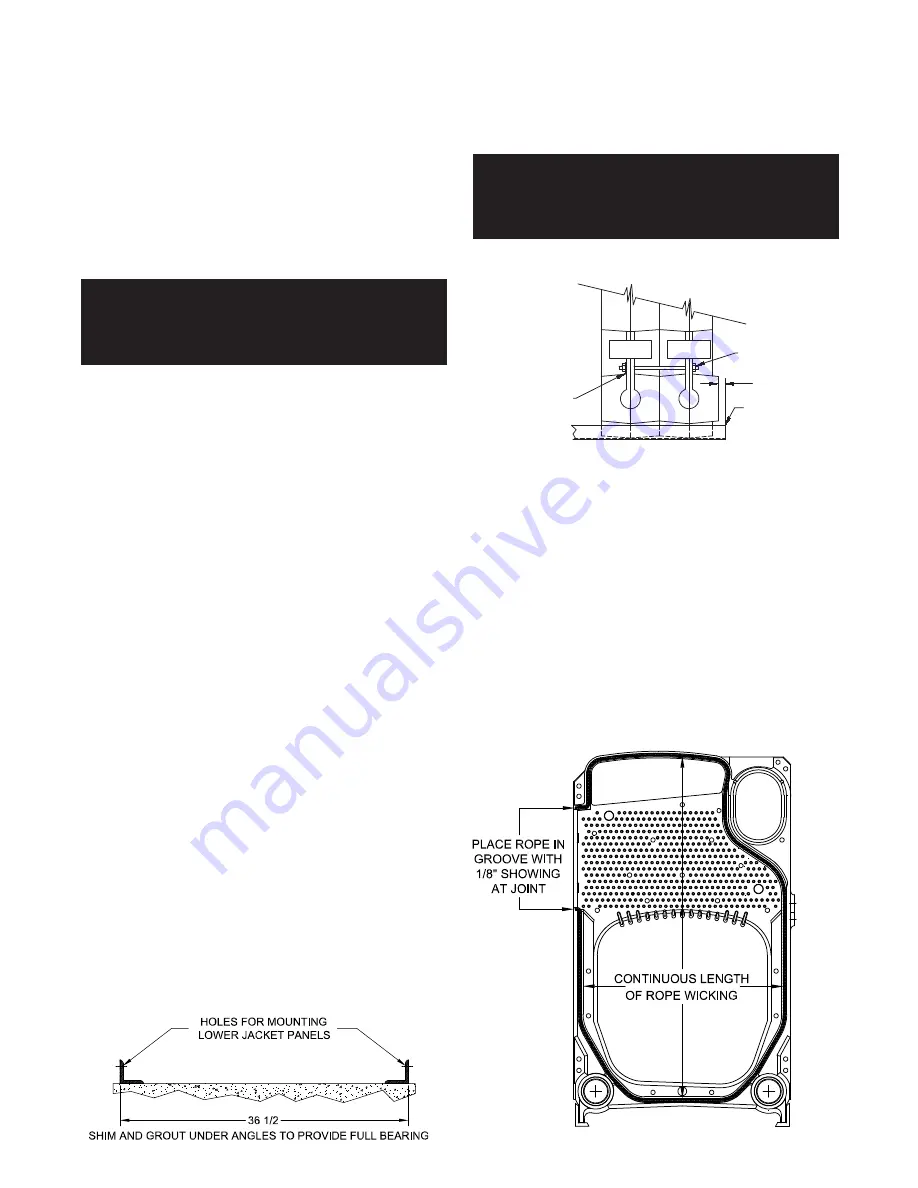

angles as shown in Figure 4.

WARNING: The section MUST be fully supported

to prevent it from falling! Failure to comply

with this warning may result property damage,

severe personal injury or death!

Figure 4 - Section Placement

3. Clean the hydronic port connector sealing surfaces

and the rope grooves with a wire brush to remove

any rust or debris.

4. Apply two coats of the spray adhesive supplied with

the boiler to the rope groove. Allow time for the fi rst

coat to dry before applying the second coat. When

the second coat is tacky press the rope into the rope

groove. Trim the rope off leaving

1/8 in

.,

3.2 mm

extending beyond the surface of the cast iron

section, Figure 5.

Figure 5 - Rope Installation

Completed boilers must be tested as follows:

Steam Boilers – the assembled boiler sections shall be

subjected to a hydrostatic test pressure of not less than

45 psig

, (

315 kPa

.)

The hydrostatic pressure shall not exceed the required

test pressure by more than

10 psig

, (

70 kPa)

during

the test.

WARNING: Never leak test the boiler using

compressed air! Failure to comply with this

warning may result in property damage, severe

personal injury or death!

1. Plug all openings in the boiler and fi ll it with water.

2. Bleed any air off through one of the top tappings

then increase the pressure as outlined above.

3. Maintain the test pressure while carefully checking

for leaks. If a leak is found it must be eliminated, see

Table 4 and supporting text. Once the assembled

boiler sections pass the hydrostatic test drain them

and remove the plugs from any tappings that will be

used in service.

4. Do not leave boiler unattended while performing

hydrostatic pre-fi re test.

NOTE: The shipping lugs, lifting lugs and metal

banding should be removed before installing the

jacket on factory assembled sections.

CAUTION: Remove the left jacket panels on fully

packaged boilers and ensure that the cleanout

covers are secure and gas tight. Loose covers could

damage the boiler.

Assembly of Knocked-Down Boilers

Drilled and tapped steel angles are furnished to provide

a level footing, ease of section assembly and a point of

jacket attachment.

1. Set the angles as shown in Figure 3. They must be

parallel and level. Grout under the angles to provide

a continuous bearing surface.

Figure 3 - Steel Angle Placement

MIN.- FLUSH

MAX. 3/8

INTER.

SECTION

BACK

SECTION

FLOOR ANGLE

FIXED NUT-NO WASHER

DO NOT TORQUE

WASHER ON SIDE TO BE

TORQUED. USE ANTISIZE

ON THREADS