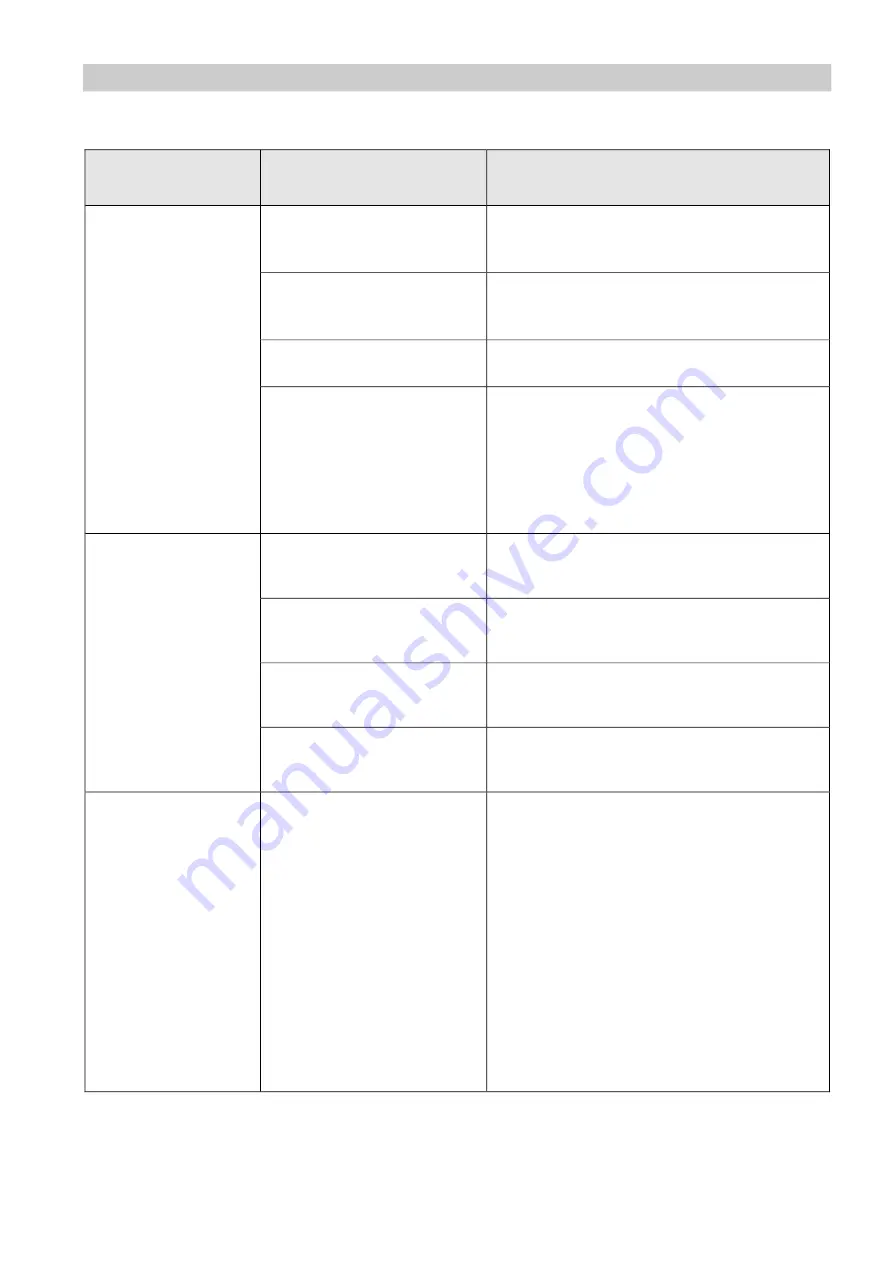

8-3 Troubleshooting

Problem

Possible cause

Solution

Rotary table does not

move

Supply pressure is not applied

correctly.

Correctly set the regulator at the supply

pressure side.

The directional switching

valve (such as a solenoid

valve) does not switch.

Correctly apply a signal to the directional

switching valve (such as a solenoid valve).

Air leakage from piping.

Inspect the piping and stop the leakage.

The restrictor in the port is

clogged.

Clean the restrictor.

Take the following countermeasures:

(1) Blow air through the piping again.

(2) Inspect the air filter.

Operation is not

smooth.

(stick-slip)

The load has some friction.

Reduce the friction resistance.

The rotation table and the item

used with it are not aligned.

Align the two centers or use a flexible fitting.

Insufficient output due to a low

supply pressure.

To obtain stable operation, adjust the supply

pressure to make the load ratio appropriate.

Speed controller is restricted

too much.

Adjust the speed controller so that the rotating

marks will be in the adjusting range.

Extreme rotating

angle changes.

Internal parts are broken.

Replace the rotary table with the new one.

After that, take the measures below.

・

Calculate the kinetic energy applied to the

rotary table and adjust the load and rotation

speed to make the value within the allowable

kinetic energy.

・

Mount an external stopper or shock absorber

to absorb the impact force

.

In this case, adjust so that the adjusting bolt

does not come into contact with the piston. Set

the rotation end with an external stopper.

-37-

2020-10-13 10:36

DI987004

Содержание CRQ2 Series

Страница 27: ...Table for calculation of Inertia moment 25...