ISSUE DATE: FEBRUARY 2018

ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018

APPROVED BY: S. GONZALEZ

PAGE 27 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

Cleaning Procedures

The fabric, header, and vane fabric are 100% polyester. They are resilient, anti-static, and dust resistant.

Periodic cleaning is recommended to help keep Luminette

®

Privacy Sheers looking like new. For all cleaning

applications, fabrics should remain hanging to minimize handling, wrinkling, or puckering.

IMPORTANT:

Disposable gloves should be worn when handling fabrics.

CAUTION:

Keep all cleaning solutions away from the SofTrak

™

headrail system. Never immerse the

headrail.

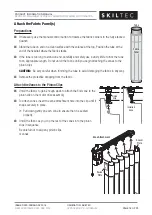

Routine Cleaning

■

Use a feather duster for regular light dusting.

■

For more thorough dust removal, a hand-held vacuum with low suction may be used. When vacuuming,

avoid pulling or stretching the fabric.

➤

Start in the upper left corner and work across the fabric using short horizontal strokes while

steadying the fabric with your free hand. Each stroke should be approximately the width of two to

three vanes. Do not use long horizontal or vertical strokes, as these actions will crease the fabric.

Continue to the bottom of the fabric.

CAUTION:

Do not use a brush attachment or rigorous vacuuming since either could distort the fabric.

Electrostatic Cleaning

CAUTION:

Do not use electrostatic cleaning devices on any Luminette product.

Spot-Cleaning

To reduce the potential for permanent staining, spots should be treated and cleaned as soon as possible

with a clothing stain pre-treatment solution.

■

Apply the pre-treatment solution to a clean, white cloth.

■

Support the fabric from behind using another clean, dry cloth. Clean the spot using a gentle blotting

action. Avoid rubbing the fabric since any abrasive action may cause it to distort.

■

Let the area air dry.

■

After the area is dry, remove excess solution by blotting it with distilled or bottled water applied to

another clean cloth.

Deep Cleaning

For deep cleaning, both injection/extraction and ultrasonic cleaning methods are recommended.

CAUTION:

Do not dry clean Luminette fabrics.